Method for producing instant fermented tea powder through liquid fermentation of microorganisms

A technology of liquid fermentation and fermented tea, applied in the field of food processing, can solve the problems of long production cycle, difficult product quality, cumbersome processing technology, etc., achieve good soup color and taste, shorten the fermentation cycle, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

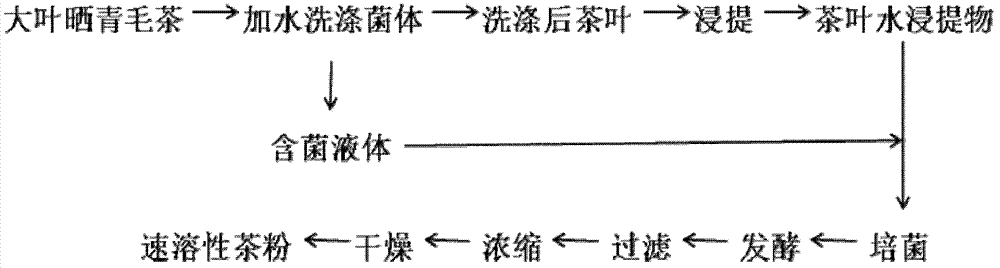

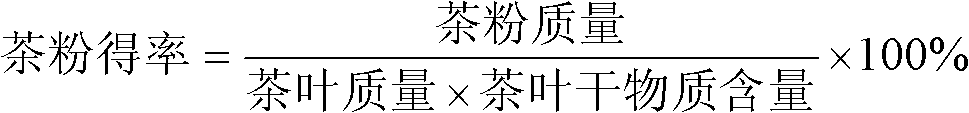

[0025] The classified Yunnan big-leaf sun-dried green hair tea is subpackaged after washing microorganisms and leaching treatments (the specific production process of instant fermented tea powder is the same as that in the above embodiment, see Process 1 figure 1 (Shown), 50ml per bottle, placed in a shaker at 30°C and a rotating speed of 120r / min, cultured for 4 days, heated to 45°C, and a fermentation period of 6 days;

[0026] After the fermentation, the fermentation broth is boiled and inactivated, centrifuged, and suction filtered to obtain fermented tea juice, which is concentrated and dried to obtain instant tea powder. The yield of instant fermented tea powder is 23.86%, of which the theafucin content is 28.55% and the tea polyphenol content is 23.19%.

Embodiment 2

[0028] After grading, the Yunnan big-leaf sun-dried green hair tea is washed and extracted (process 1), cultured and fermented in a 30L fermentor at 35°C, 100r / min, and the fermentation cycle is 6d (specific production process Same as above);

[0029] After the fermentation, the fermentation broth is boiled to inactivate, centrifuged, filtered, and dried to obtain instant tea powder. The yield of instant fermented tea powder is 26.70%, the content of the brown pigment is 25.65%, and the content of tea polyphenol is 24.42%.

Embodiment 3

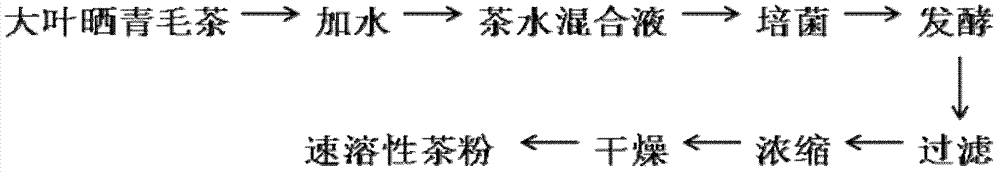

[0031] After the classification treatment, Yunnan Dayezhong Sun-dried Green Hair Tea is directly added to 35℃ water to obtain a tea-water mixture (such as figure 2 The instant fermented tea powder production process 2), each bottle of 70ml, placed in a shaker at 35°C, 100r / min, cultured for 4 days, heated to 45°C, and a fermentation period of 14 days; after the fermentation, it was subjected to coarse filtration and microfiltration. The instant tea powder can be obtained by filtering, concentrating and drying (the specific production process is the same as the above embodiment).

[0032] The yield of instant fermented tea powder is 25.09%, the content of the brown pigment is 16.38%, and the content of tea polyphenol is 24.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com