Application of papermaking white clay in biological fermentative hydrogen production

A technology for papermaking white mud and biological fermentation, which is applied to fermentation and other directions, can solve the problems of high cost, high energy consumption, complex process and the like, and achieves the effects of high hydrogen production rate, improved hydrogen production rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

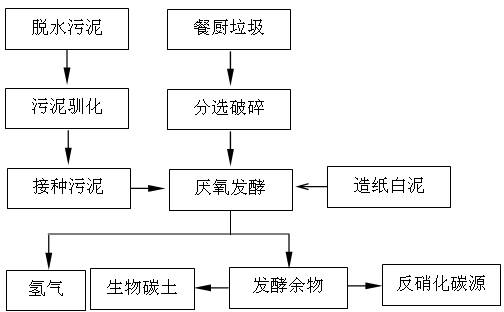

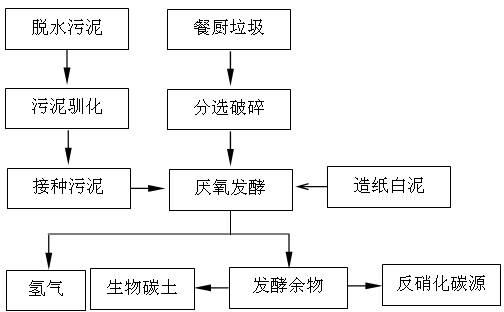

Image

Examples

Embodiment 1

[0021] Fill the bucket with dewatered sludge from the sewage plant (about 80% water content) to remove impurities such as silt, grass, etc., cover it and leave it for 10 to 20 days to create an anaerobic environment, remove the aerobic bacteria in it, and then Take 100g of dewatered sludge from the lower part of the barrel, put it into a fermentation bottle, seal it, and heat it at 80°C for 0.5h, then add 1.2g of glucose and 1g of peptone, shake well, and seal it. The fermentation bottle is acclimatized at 50-53°C, and the sludge is acclimated until no gas is produced, the time is 20-30h, and the acclimated sludge is recorded as inoculation sludge. Add the obtained inoculated sludge, 100g of kitchen waste, and 3g of papermaking white mud into the fermentation bottle, add water to ensure that the solid content is 5-10% (preferably 6-8%), shake well, seal, and control the fermentation reaction temperature at 50-53 ℃, the hydrogen yield is 83.18mLH 2 / gVS, after 12-18 hours of f...

Embodiment 2

[0023] Take 100g of the sludge left in anaerobic state for 10-20 days in Example 1, put it into a fermentation bottle, seal it, and heat-treat it at 85°C for 20min, then add 2g of glucose and 0.9g of peptone, shake well, and seal it. The fermentation bottle is acclimatized at 50-53°C, and the sludge is acclimated until no gas is produced, and the time is 20-30 hours. The acclimatized sludge is recorded as inoculation sludge. Add the obtained inoculated sludge, 100g of kitchen waste, and 5g of papermaking white mud into the fermentation bottle, add water to ensure that the solid content is 5-10% (preferably 6-8%), shake well, seal, and control the reaction temperature of dark fermentation at 50-50% 53°C, the hydrogen yield is 97.76mLH 2 / gVS, after 14-20 hours of fermentation time, the process basically ends.

Embodiment 3

[0025] Take 100g of the sludge left in the anaerobic state of Example 1 for 10-20 days, put it into a fermentation bottle, seal it, and heat-treat it at 83°C for 25 minutes, then add 0.9g of glucose and 1.2g of peptone, shake well, and seal it. The fermentation bottle was acclimated at 53°C, and the sludge was acclimated until no gas was produced, and the time was 20-30 hours. The acclimated sludge was recorded as inoculation sludge. Add the obtained inoculated sludge, 100g of kitchen waste, and 7g of papermaking white mud into the fermentation bottle, add water to ensure that the solid content is 5-10% (preferably 6-8%), shake well, seal, and control the reaction temperature of dark fermentation at 50-50% 53°C, the hydrogen yield is 108.64mLH 2 / gVS, after 14-20 hours of fermentation time, the process basically ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com