Composition of halogen-free flame-retardant polystyrene plastic and preparation method thereof

A technology of polystyrene and plastics, applied in the field of flame-retardant plastic formulation and its preparation, can solve the problem of reducing the mechanical properties and processing properties of polystyrene plastics, the decrease of impact strength, and the decrease of tensile strength of high-impact polystyrene And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

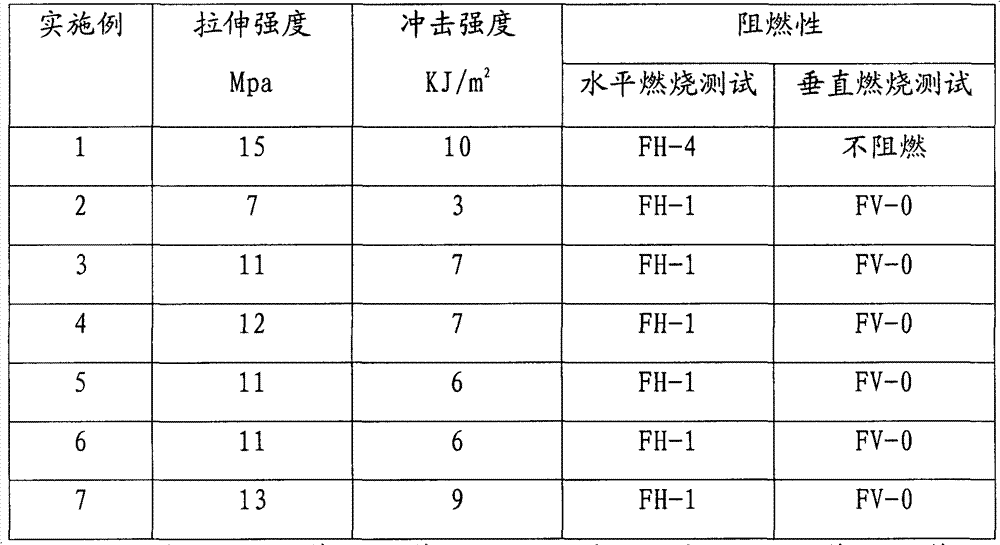

Examples

Embodiment 1

[0020] Embodiment 1 of the present invention: a formula of halogen-free flame-retardant polystyrene plastics, which includes 100 parts of high-impact polystyrene (HIPS), silicone rubber and its vulcanized crosslinking agent in parts by weight 15 parts, 5 parts of toughening agent styrene-butadiene-styrene block copolymer (SBS), 0.5 part of silane coupling agent (KH550), 2 parts of ethylene bis fatty acid amide (EBS) and liquid paraffin 0.5 parts of processing aids composed of 2.5 parts.

[0021] A method for preparing halogen-free flame-retardant polystyrene plastics. According to the parts by weight of the above formula, the silane coupling agent (KH550), organic silicon rubber and its vulcanized crosslinking agent are mixed and granulated through an open mill , to obtain pellets B; pellets B and high impact polystyrene (HIPS), styrene-butadiene-styrene block copolymer (SBS), ethylene bis fatty acid amide (EBS), liquid paraffin Together, they are extruded and granulated by a...

Embodiment 2

[0023] Embodiment 2 of the present invention: a formula of halogen-free flame-retardant polystyrene plastics, which includes 100 parts of high-impact polystyrene (HIPS), silicone rubber and its vulcanized crosslinking agent in parts by weight 30 parts, 100 parts of magnesium hydroxide, 20 parts of red phosphorus, 15 parts of block copolymer (SBS) of toughening agent styrene-butadiene-styrene, 0.5 part of silane coupling agent (KH550), made of liquid paraffin 0.5 parts and 2.5 parts of processing aids composed of 2 parts of ethylene bis fatty acid amide (EBS).

[0024] A method for preparing halogen-free flame-retardant polystyrene plastics, comprising placing magnesium hydroxide, red phosphorus, and a silane coupling agent (KH550) in a blender and stirring evenly according to the parts by weight of the above formula to obtain a stirring material A; Mixing material A, silicone rubber and its vulcanized crosslinking agent are mixed and granulated by an internal mixer to obtain p...

Embodiment 3

[0026] Embodiment 3 of the present invention: a formula of halogen-free flame-retardant polystyrene plastics, which includes 100 parts of high-impact polystyrene (HIPS), silicone rubber and its vulcanized crosslinking agent in parts by weight 22.5 parts, 70 parts of magnesium hydroxide, 8 parts of red phosphorus, 10 parts of block copolymer (SBS) of toughening agent styrene-butadiene-styrene, 0.5 part of silane coupling agent (KH550), made of liquid paraffin 0.5 parts and 2.5 parts of processing aids composed of 2 parts of ethylene bis fatty acid amide (EBS).

[0027] A method for preparing halogen-free flame-retardant polystyrene plastics, comprising placing magnesium hydroxide, red phosphorus, and a silane coupling agent (KH550) in a blender and stirring evenly according to the parts by weight of the above formula to obtain a stirring material A; Mixing material A, silicone rubber and its vulcanized crosslinking agent are mixed and granulated by an internal mixer to obtain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com