Composition for preparing polyethylene pipe with superhigh molecular weight and preparation method thereof

An ultra-high molecular weight, composition technology, applied in the field of plastic processing, can solve the problems of not mentioning the thermal oxygen aging performance, high energy consumption, affecting the service life of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

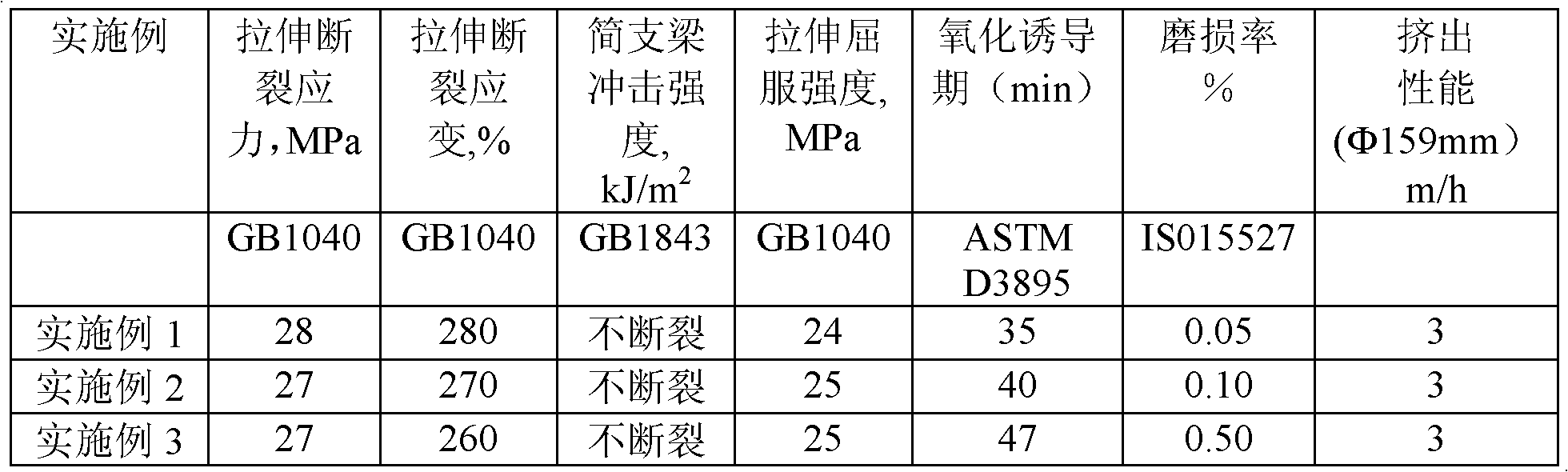

Examples

Embodiment 1

[0032] Embodiment 1 (dosing ratio is mass parts, hereinafter the same)

[0033] Ultra-high molecular weight polyethylene (viscosity average molecular weight 120×10 4 ) 100

[0034] Polyethylene wax 2

[0035] Calcium stearate 0.2

[0036] Zinc stearate 0.5

[0037] Compound antioxidant 0.1

[0038] **(Fluoropolymer processing aid FX-5920 0.1

[0039] carbon black 2

[0040] The required raw materials are all commercially available products, of which, ** (the fluoropolymer processing aid FX-5920 is the fluoropolymer processing aid PPA series product of the American 3M company (for example, FX-5911, 5920, 5924) One of the models, also known as "rheology agent", "brightener", "slip agent" and so on in some fields. It is a kind of fluorine-containing polymer-based structure developed by 3M company of the United States. Additives that help you improve the processability of your polymers.

[0041] The following embodiments are the same.

Embodiment 2

[0043] Ultra-high molecular weight polyethylene (viscosity average molecular weight 185×10 4 ) 100

[0044] Polyethylene wax 3

[0045] Calcium stearate 0.3

[0046] Zinc stearate 0.1

[0047] Compound antioxidant 0.2

[0048] Fluoropolymer processing aid FX-5920 0.08

[0049] Carbon black 1.5

Embodiment 3

[0051] Ultra-high molecular weight polyethylene (viscosity average molecular weight 202×10 4 ) 100

[0052] Polyethylene wax 4

[0053] Calcium stearate 0.2

[0054]Zinc stearate 0.5

[0055] Compound antioxidant 0.3

[0056] Fluoropolymer processing aid FX-5920 0.06

[0057] Carbon black 1.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com