Rubber diaphragm synthetic material for pressure-bearing gas pressure regulator, and preparation method of rubber diaphragm synthetic material

A technology for gas pressure regulators and synthetic materials, applied in mechanical equipment, functional valve types, balance valves, etc., can solve the problems that rubber diaphragms cannot meet the requirements of high-pressure gas pressure regulators, and achieve improved physical and mechanical properties and compression permanent deformation small size, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

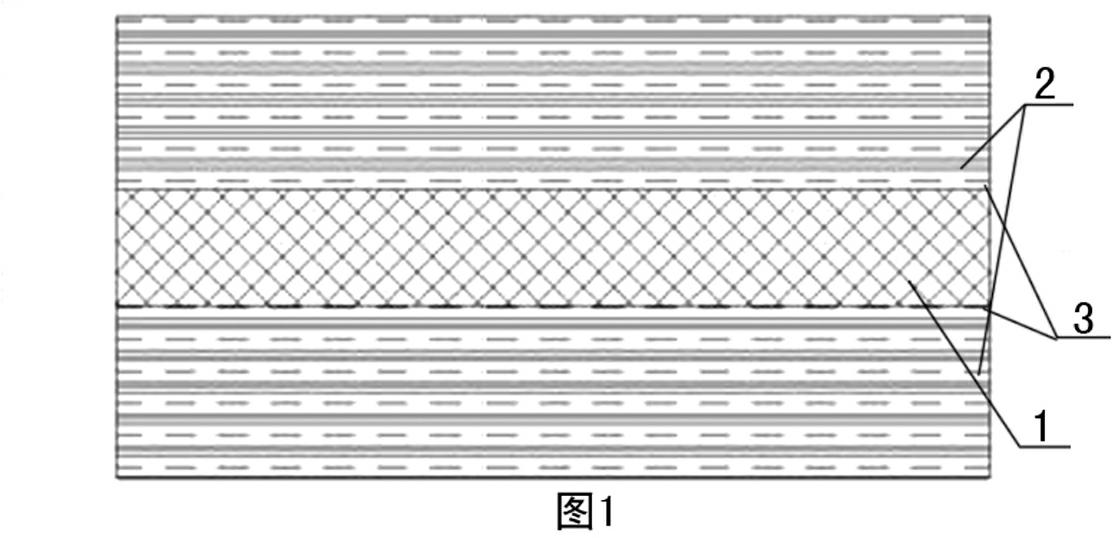

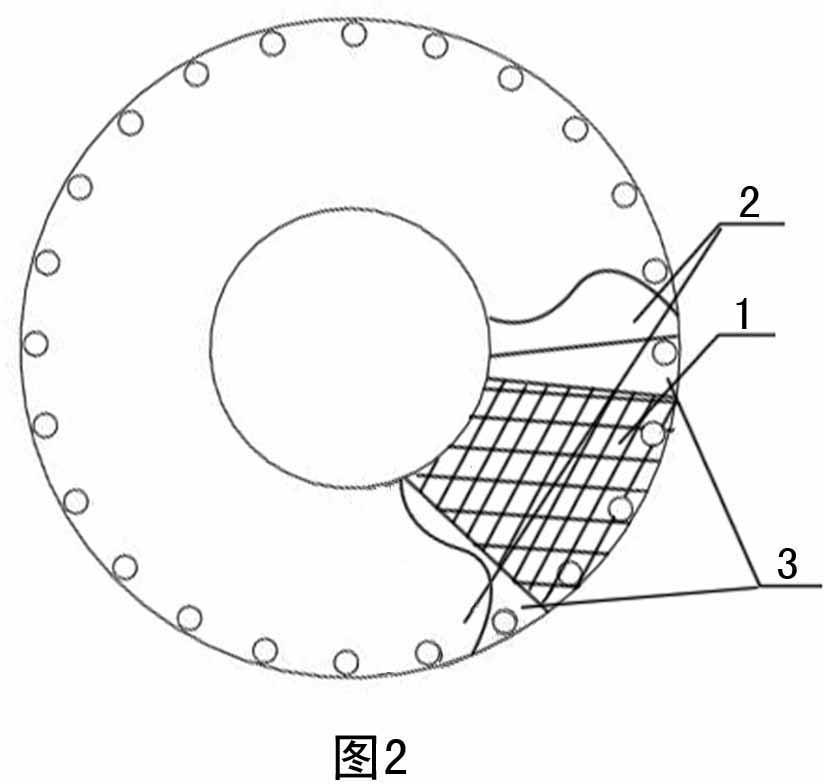

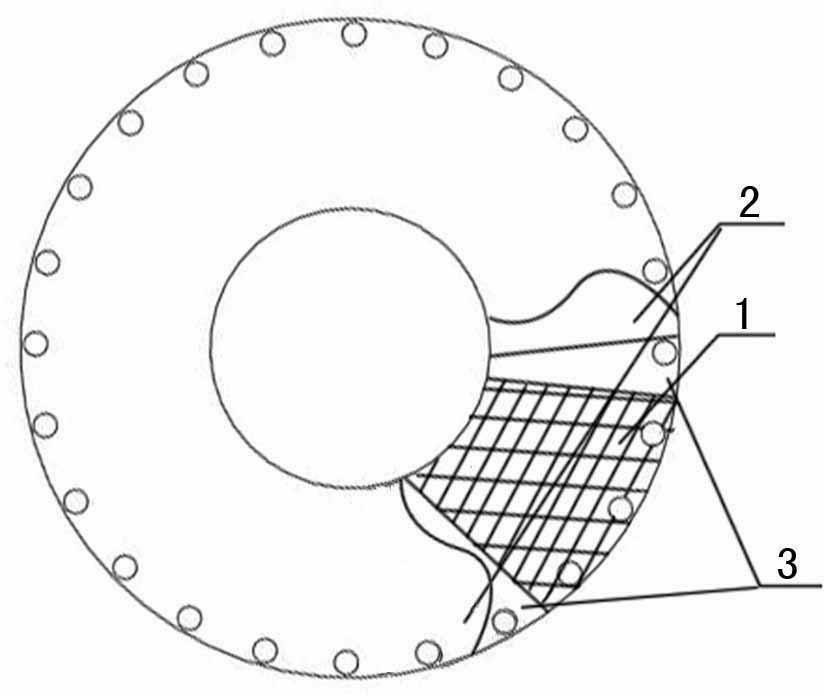

Image

Examples

Embodiment

[0028] Embodiment sees the following table: the present invention is described in detail below by general diaphragm formula and embodiment formula:

[0029] Rubber diaphragm general formula and the embodiment formula of the present invention

[0030]

[0031] Note: Nitrile rubber: domestic; Chlorinated polyethylene: domestic; other conventional reagents are commercially available.

[0032] Among them, silica is a reinforcing agent; stearic acid and zinc oxide are activators; DOP is a general-purpose plasticizer; light calcium carbonate is a filler; paraffin is also one of the anti-aging agents, and its main function is to improve ozone resistance. , anti-aging; CZ and TT are vulcanization accelerators; sulfur S is a vulcanization agent.

[0033] The preparation process of above-mentioned each embodiment formula is as follows:

[0034] (1) The first stage of mixing: add nitrile rubber and chlorinated polyethylene and knead for 0.5-1min at 50-80℃, then add zinc oxide, stear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com