Preparation method of high viscosity cationic starch

A cationic starch and high-viscosity technology, which is applied in the field of modified starch, can solve the problems that the processing technology cannot meet the needs of the market, and achieve the effects of shortening the dosing time, improving the uniformity of the reaction, and scientific and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

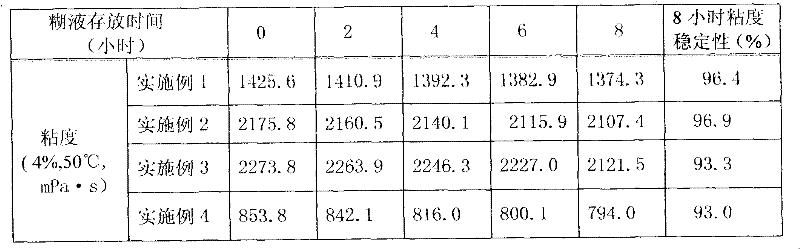

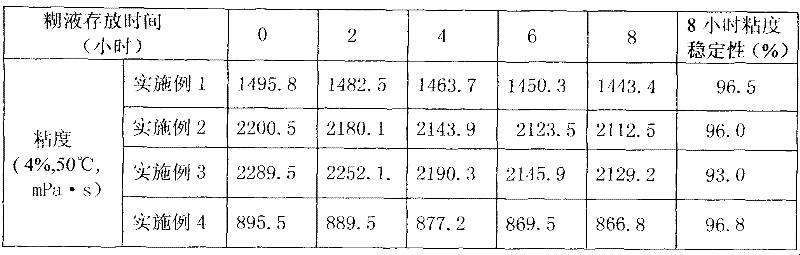

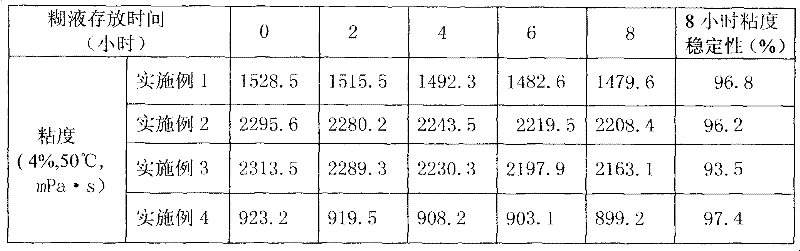

Embodiment 1

[0027] 2kg concentration is the fresh cassava starch slurry of 43% (or adjusts starch slurry with former starch), is 0.3: 1, the aqueous solution of concentration is 20% to regulate starch slurry PH=10 with sodium hydroxide and sodium sulfate mass ratio; Heating while While adding the mixture that is prepared by 30% sodium hydroxide and 56g concentration of 69% 3-chloro-2-hydroxypropyltrimethylammonium chloride by 26g concentration, the mixture is added before the starch slurry temperature reaches 40 ℃. When the temperature reaches 40°C, stop heating; use an aqueous solution with a mass ratio of sodium hydroxide and sodium sulfate of 0.3:1 and a concentration of 20% to adjust the pH of the starch slurry to 11.5; heat up to 49-50°C, and react for 3 hours; The mass ratio of sodium to sodium sulfate is 0.3:1, 3.0ml of an aqueous solution with a concentration of 20%, add 0.08ml of epichlorohydrin and mix well, then add it to the starch slurry, and react for 3.5 hours; dehydrate the...

Embodiment 2

[0029] 2kg concentration is 43% fresh cassava starch slurry (or adjusts starch slurry with former starch), is 0.35: 1, the mixed aqueous solution that concentration is 20% to regulate starch slurry PH=11 with potassium hydroxide and sodium sulfate mass ratio; Add a mixture of 57.4g of 30% sodium hydroxide and 118.4g of 69% 3-chloro-2-hydroxypropyltrimethylammonium chloride while heating, before the temperature of the starch slurry reaches 40°C After adding the mixture, stop heating when the temperature reaches 40°C; use a mixed aqueous solution with a mass ratio of potassium hydroxide and sodium sulfate of 0.35:1 and a concentration of 20% to adjust the pH of the starch slurry to 11.5; raise the temperature to 49-50°C, and react for 3.5 hours ; Take potassium hydroxide and sodium sulfate mass ratio is 0.35: 1, concentration is 20% mixed aqueous solution 4.4ml, add 0.11ml epichlorohydrin to mix, then add in starch slurry, react for 2.5 hours; Starch slurry is dehydrated , to ob...

Embodiment 3

[0031] 2kg concentration is the potato starch slurry of 43%, with potassium hydroxide and sodium chloride mass ratio is 0.3: 1, concentration is the mixed aqueous solution of 20% to adjust starch slurry pH=11.5; A mixture of potassium hydroxide and 62.3g of 3-chloro-2-hydroxypropyltrimethylammonium chloride with a concentration of 69%. Add the mixture before the starch slurry temperature reaches 40°C, and stop when the temperature reaches 40°C Heating; adjust the pH of the starch slurry to 12 with a mixed aqueous solution of potassium hydroxide and sodium chloride with a mass ratio of 0.3:1 and a concentration of 20%; heat up to 49-50°C and react for 2.5 hours; take potassium hydroxide and sodium chloride Mix 4.0ml of aqueous solution with a mass ratio of 0.3:1 and a concentration of 20%, add 0.13ml of epichlorohydrin and mix evenly, then add it to the starch slurry, and react for 5 hours; dehydrate the starch slurry to obtain a wet solution with a water content of about 30%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com