System and method for processing rubbish percolate

A landfill leachate and treatment system technology, which is applied in the field of waste water treatment equipment, can solve the problems of poor treatment effect and inability to treat landfill leachate, and achieve better treatment effect, strong resistance to membrane pollution, simple and effective treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

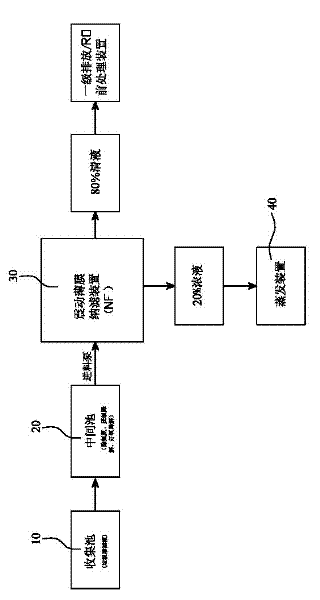

[0070] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a collection tank 10 , an intermediate tank 20 , a vibrating membrane nanofiltration device (NF) 30 and an evaporation device 40 .

[0071] Among them, such as figure 1 As shown, the collection tank 10 is used to collect landfill leachate.

[0072] The intermediate tank 20 is used to remove ammonia nitrogen, anaerobic degradation and aerobic degradation treatment for the landfill leachate. After degradation treatment, the COD content in the landfill leachate is 500-1000ppm, NH 3 The content of -N is less than 1 ppm, and the content of SS is about 100 ppm.

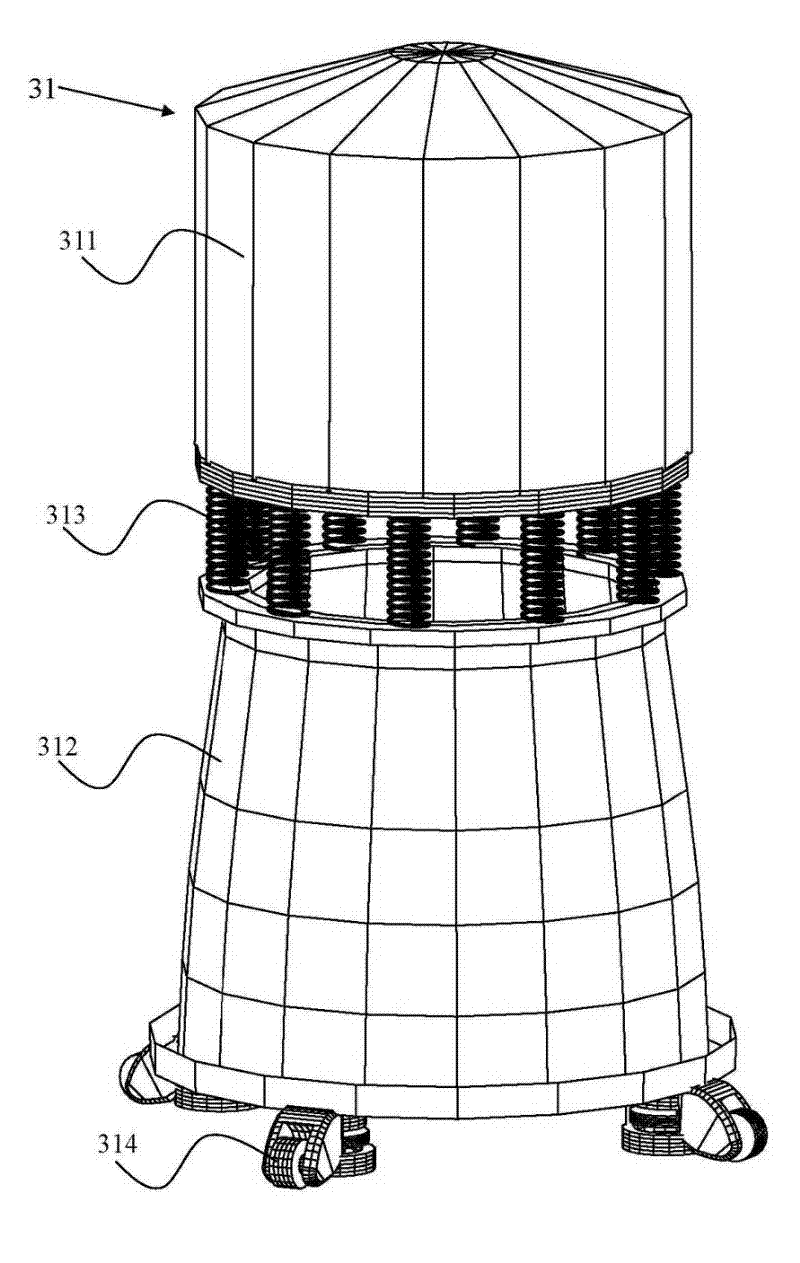

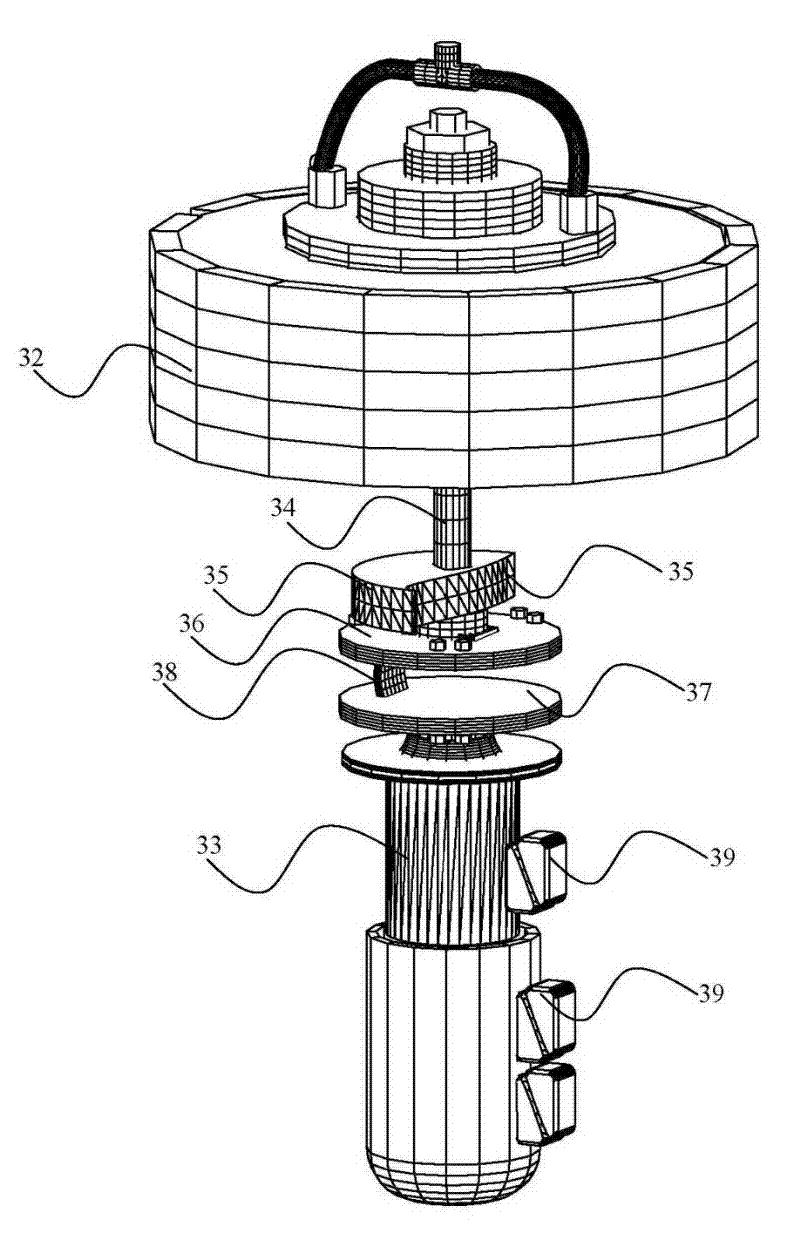

[0073] The vibrating membrane nanofiltration device (NF) 30 is used to filter and separate landfill leachate to form clear liquid and concentrated liquid, which includes an organic casing 31 and a membrane group 32 and a motor 33 installed in the casing 31 .

[0074] Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com