Method for treating acidic wastewater with high arsenic content by using nano TiO2 and recycling arsenic

A technology for arsenic fouling acid and arsenic recovery, applied in the field of environmental science, can solve the problems of large amount of sediment, high arsenic content, high transportation, storage, and processing costs, and achieves the solution of secondary environmental pollution, reduced cost input, and amount of sediment. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

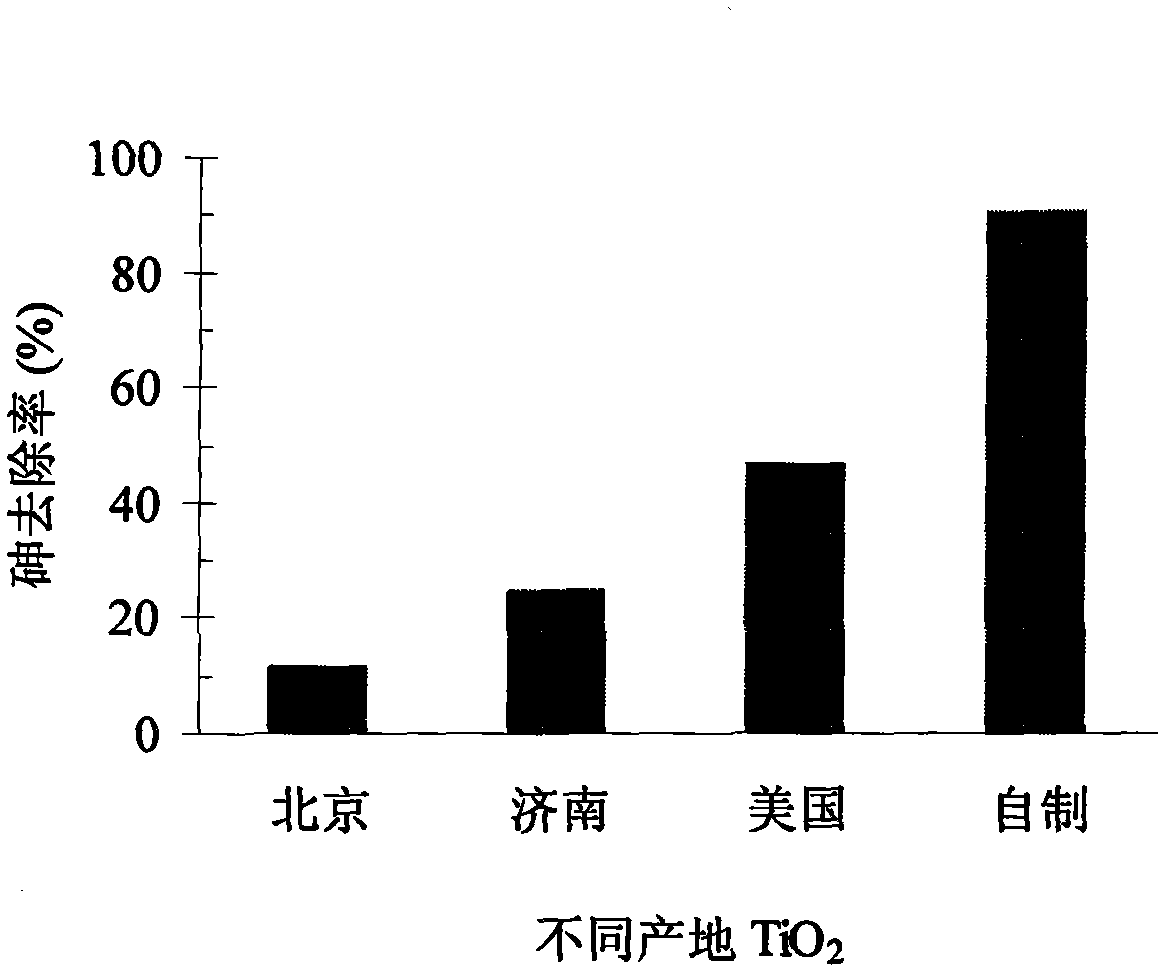

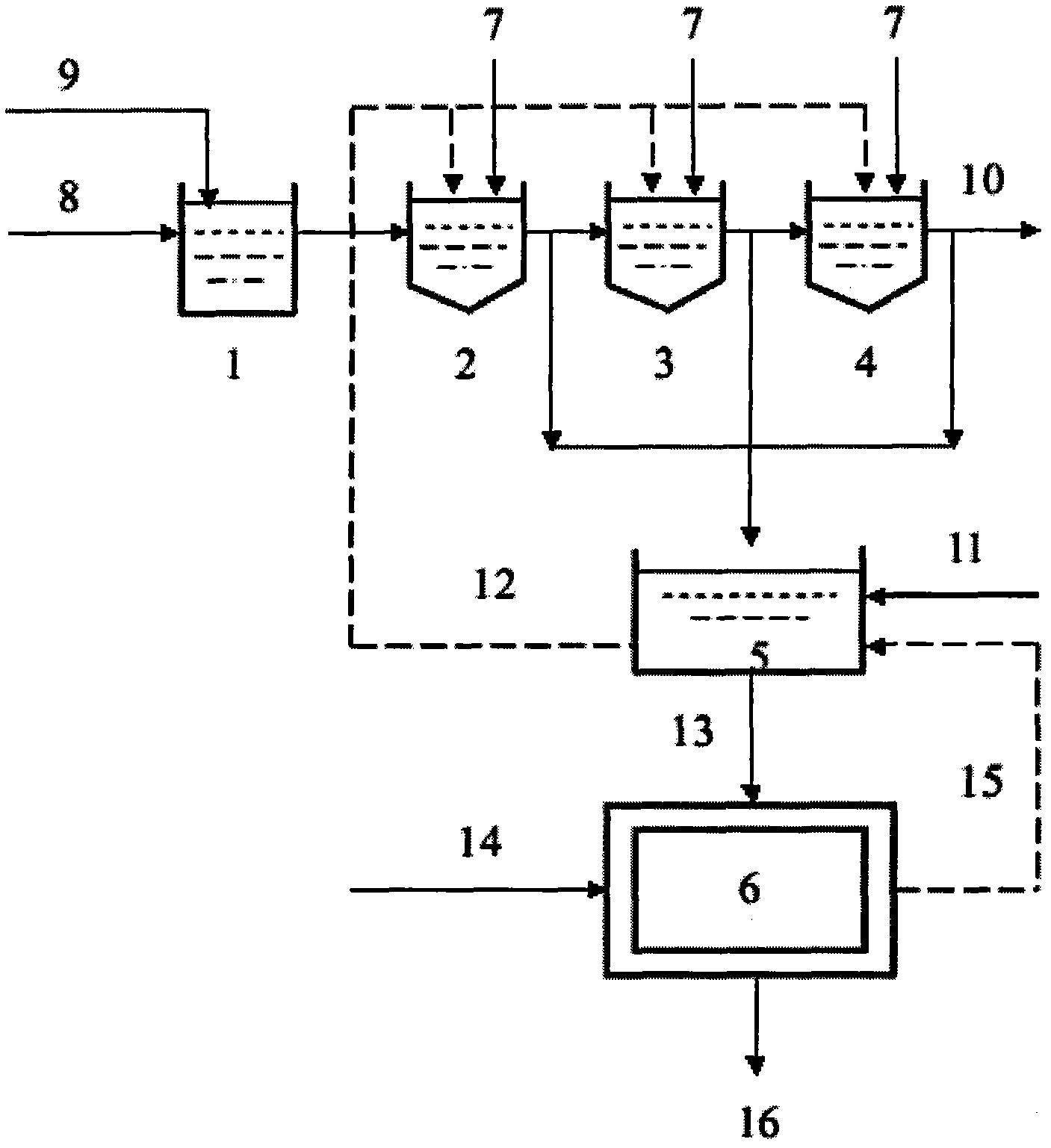

Embodiment 1

[0041] The wastewater samples were collected from the high arsenic-containing wastewater discharged from the sulfuric acid workshop of a copper smelter. The composition is shown in Table 1. Add lime milk to the wastewater, adjust the pH value to 5, and separate the solid and liquid with a centrifuge. The separated filtrate enters three reaction tanks for step-by-step adsorption, and 30g / L TiO is added to each of the three reaction tanks. 2 The pH value of the adsorbent was adjusted to 7, and the reaction time of each stage of adsorption was 1 hour. In each reaction tank the pH was adjusted to 7, with TiO 2 The adsorbent (30 g / L) was reacted for 1 hour, and after the adsorption reaction was completed, solid-liquid separation was performed. In order to ensure the removal of cadmium, the filtrate obtained after the third-stage adsorption was passed into the fourth reaction tank for adsorption and centrifugation.

[0042] The arsenic concentration and heavy metal concentration ...

Embodiment 2

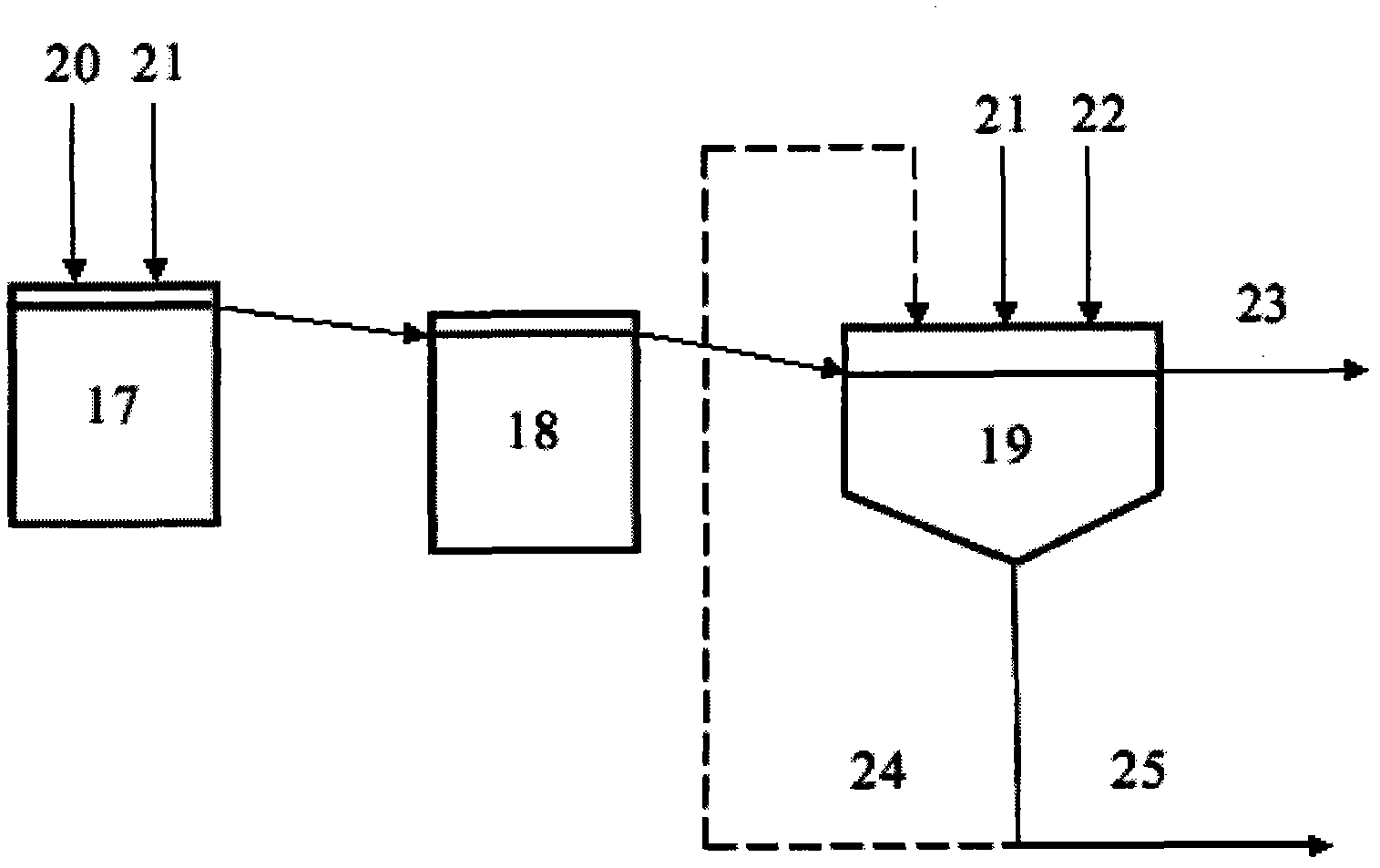

[0049] After the same wastewater as in Example 1 was treated in the reaction tank, solid-liquid separation was achieved by centrifugation. After testing, the concentration of arsenic and heavy metal ions in the filtrate meets the emission requirements, and the solid after adsorption of arsenic, namely TiO 2 The adsorbent was passed into the alkali elution tank, and 2 mol / L NaOH solution was added (the volume of NaOH added: the volume of wastewater in the reaction tank=1:10), and after stirring and elution for 30 minutes, the solid-liquid centrifugation was performed. TiO after alkaline washing 2 Pass into the reaction tank (1, 2, 3) and reuse it to remove arsenic in wastewater. The eluate containing high concentrations of arsenic enters the arsenic recovery tank.

[0050] Elution rate of arsenic and TiO after regeneration 2 The effect of removing arsenic is shown in Figure 4 and Figure 5 . Figure 4 showed that the average elution rate of arsenic was higher than 70%, i...

Embodiment 3

[0052] The same waste water source and treatment process as Example 1 and Example 2, the eluent containing high-concentration arsenic produced in Example 2 is passed into the arsenic recovery tank, and calcium oxide is added to precipitate arsenic (calcium oxide adds mass: Mass of arsenic in eluent = 1:1). The initial concentration of arsenic in the eluent and the detection results of the concentration of arsenic after adding calcium oxide are shown in Table 3.

[0053] The results show that when the mass ratio of CaO addition to arsenic is 10:1, 96% of the arsenic in the backwash can be recovered, but using 10 times the amount of CaO to recover arsenic will produce more sludge, so in practical applications , using 1 times the dosage of CaO. It can be seen from Table 3 that when the mass ratio of CaO addition to arsenic is 1:1, the average recovery rate of arsenic is 77%, which can not only recover most of the arsenic in the backwash, but also avoid excessive use of CaO. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com