Core-shell structural anode catalyst for direct borohydride fuel cells and preparation method thereof

A core-shell structure, borohydride technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, battery electrodes, etc. It can improve the utilization rate, high activity and less hydrogen evolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

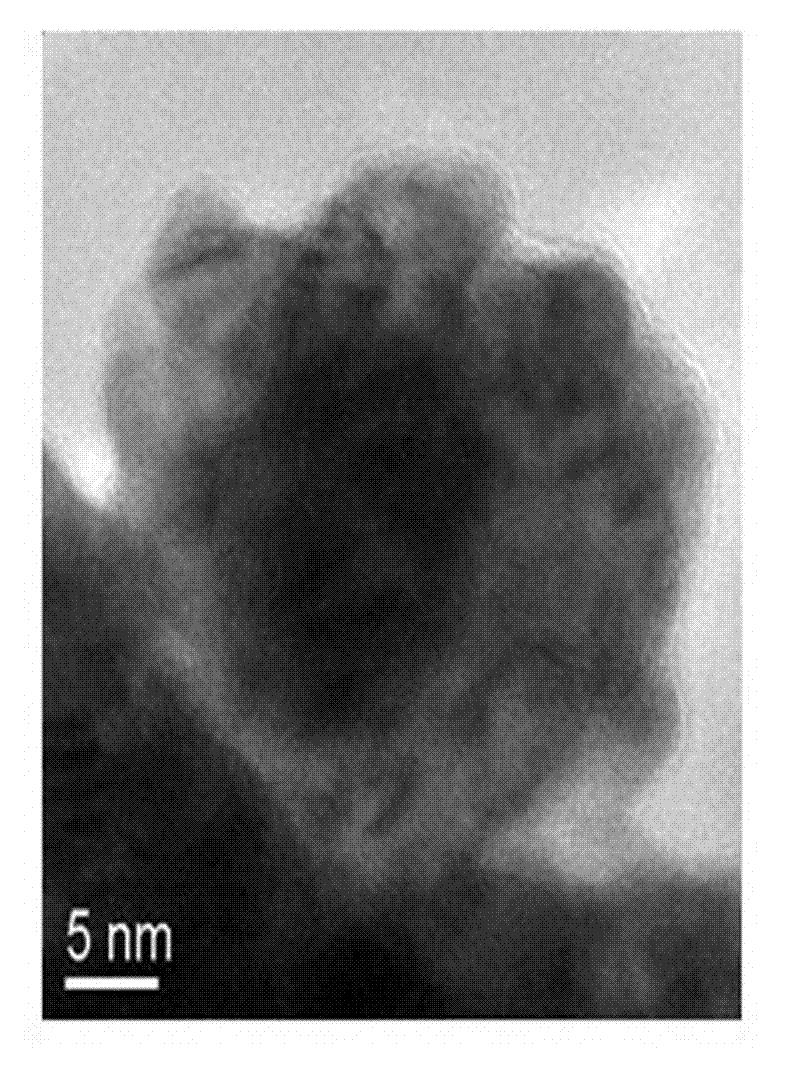

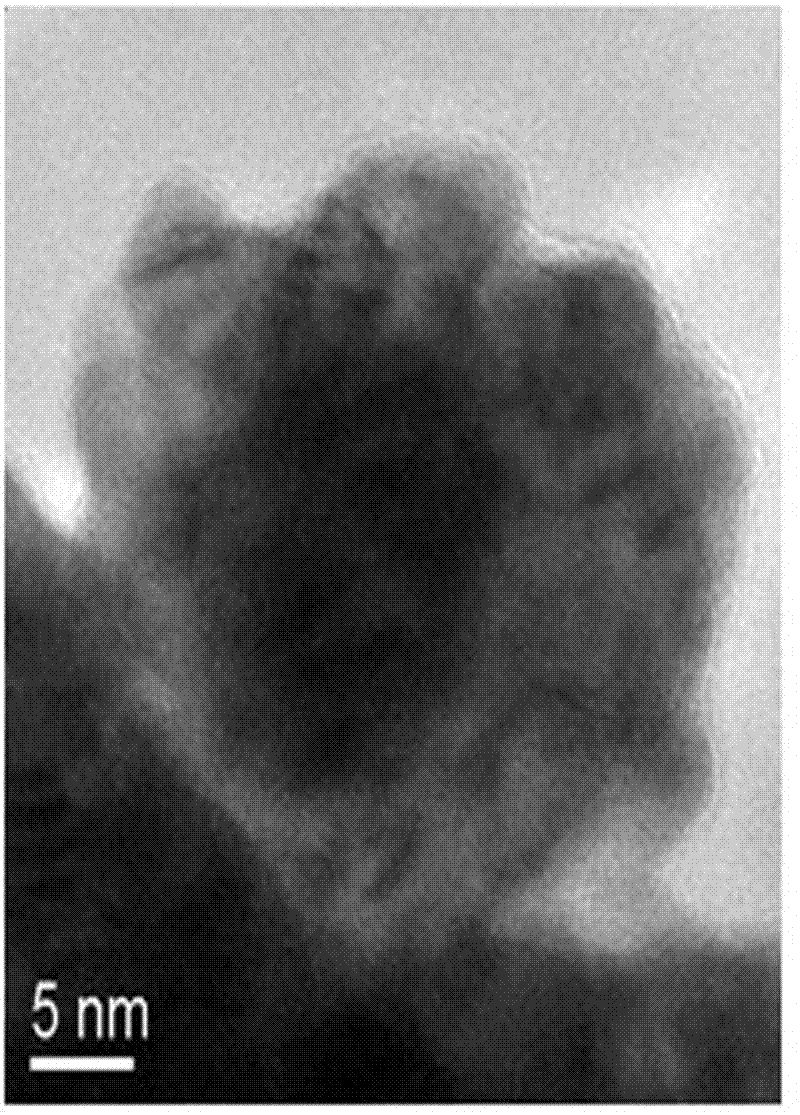

Image

Examples

Embodiment 1

[0032] (1) Preparation of Cu nanoparticles: Cu(NO 3 )·3H 2 O and polyvinylpyrrolidone (PVP) were sequentially added to 20 ml of ethylene glycol, so that the concentration of Cu atoms in ethylene glycol was 20 mmol / L, and polyvinylpyrrolidone (PVP) in ethylene glycol The concentration is 3 g / L. Stir and pass nitrogen gas for 25 minutes to make it fully mixed, then heat to 60°C, continue to pass nitrogen gas and stir continuously, and the dropwise concentration is 0.3 mol L -1 Hydrazine hydrate solution, the molar amount of hydrazine hydrate added is twice that of Cu element, and the dropping rate is 40 drops·min -1 , reacted for 40 min to prepare Cu nano catalyst sol, then suction filtered and washed with distilled water to obtain Cu nanoparticles;

[0033] (2) Re-dissolve the Cu nanoparticles in the above (1) in 20 ml of ethylene glycol, add polyvinylpyrrolidone (PVP) under stirring to make the concentration 3 g / L, blow in nitrogen and stir For 30 minutes, add a tetrahydro...

Embodiment 2

[0036] (1) Preparation of Ni nanoparticles: NiCl 2 ·6H 2 O and tetraoctylammonium bromide were added to 20ml of water in turn, so that the concentration of Ni atoms in the water was 10 mmol / L, and the concentration of tetraoctylammonium bromide in water was 1.5 g / L. Stir and pass nitrogen gas for 20 minutes to make it fully mixed, then heat to 50°C, continue to pass nitrogen gas and stir constantly, the dropwise concentration is 0.3 mol L -1 Lithium triethyl borohydride solution, adding lithium triethyl borohydride molar weight is 1.5 times that of Ni element, and the dropping speed is 40 drops min -1 , and reacted for 40 min to prepare Ni nano catalyst sol, then suction filter and wash with distilled water to obtain Ni nanoparticles;

[0037] (2) Re-dissolve the M nanoparticles in the above (1) in 20 ml of water, add tetraoctyl ammonium bromide under stirring, the concentration of tetraoctyl ammonium bromide is 1.5g / L, blow in nitrogen and stir for 30 Minutes, then add a t...

Embodiment 3

[0040] (1) Preparation of Pt nanoparticles: H 2 PtCl 6 ·6H 2 O and polyethylene glycol were sequentially added to 20 ml of tetrahydrofuran, so that the concentration of Pt atoms in tetrahydrofuran was 30 mmol / L, and the concentration of polyethylene glycol in tetrahydrofuran was 5 g / L. Stir and pass nitrogen gas for 30 minutes to make it fully mixed, then heat to 80°C, continue to pass nitrogen gas and stir constantly, the dropwise concentration is 0.3 mol L -1 Sodium borohydride solution, the molar weight of sodium borohydride added is 2.5 times that of Pt element, and the dropping rate is 40 drops·min -1 , reacted for 60 min, prepared Pt nano catalyst sol, then suction filtered, and washed with distilled water to obtain Pt nanoparticles;

[0041] (2) Redissolve the Pt nanoparticles in the above (1) in 20ml tetrahydrofuran, add polyethylene glycol under stirring, the concentration of polyethylene glycol is 5g / L, blow in nitrogen and stir for 30 minutes, and then , the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com