Expandable polystyrene resin particles and process for producing same

A technology of polystyrene and resin particles, which can be used in heating methods, air conditioning systems, applications, etc., and can solve the problems of reduced thermal insulation effect of glass wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

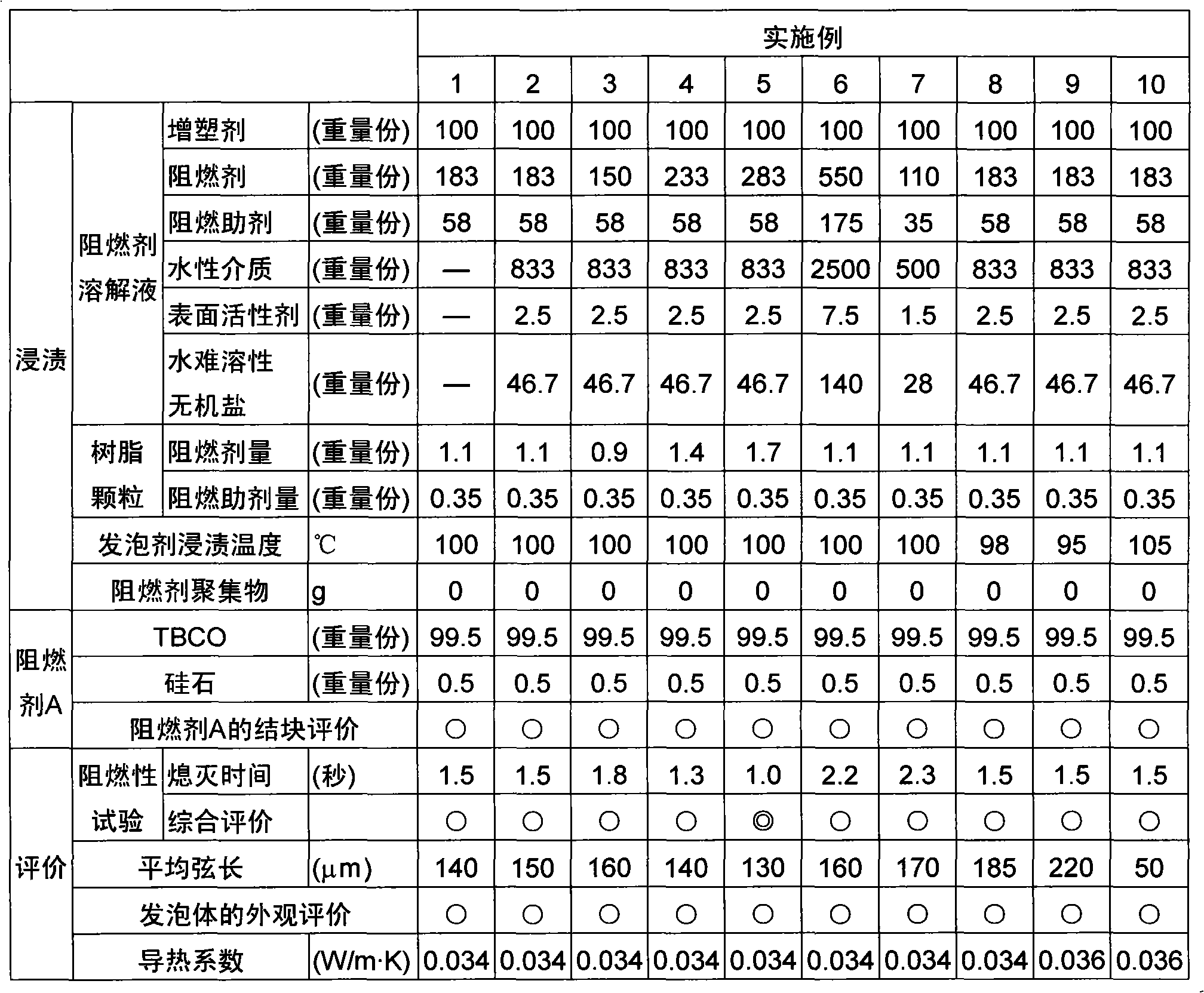

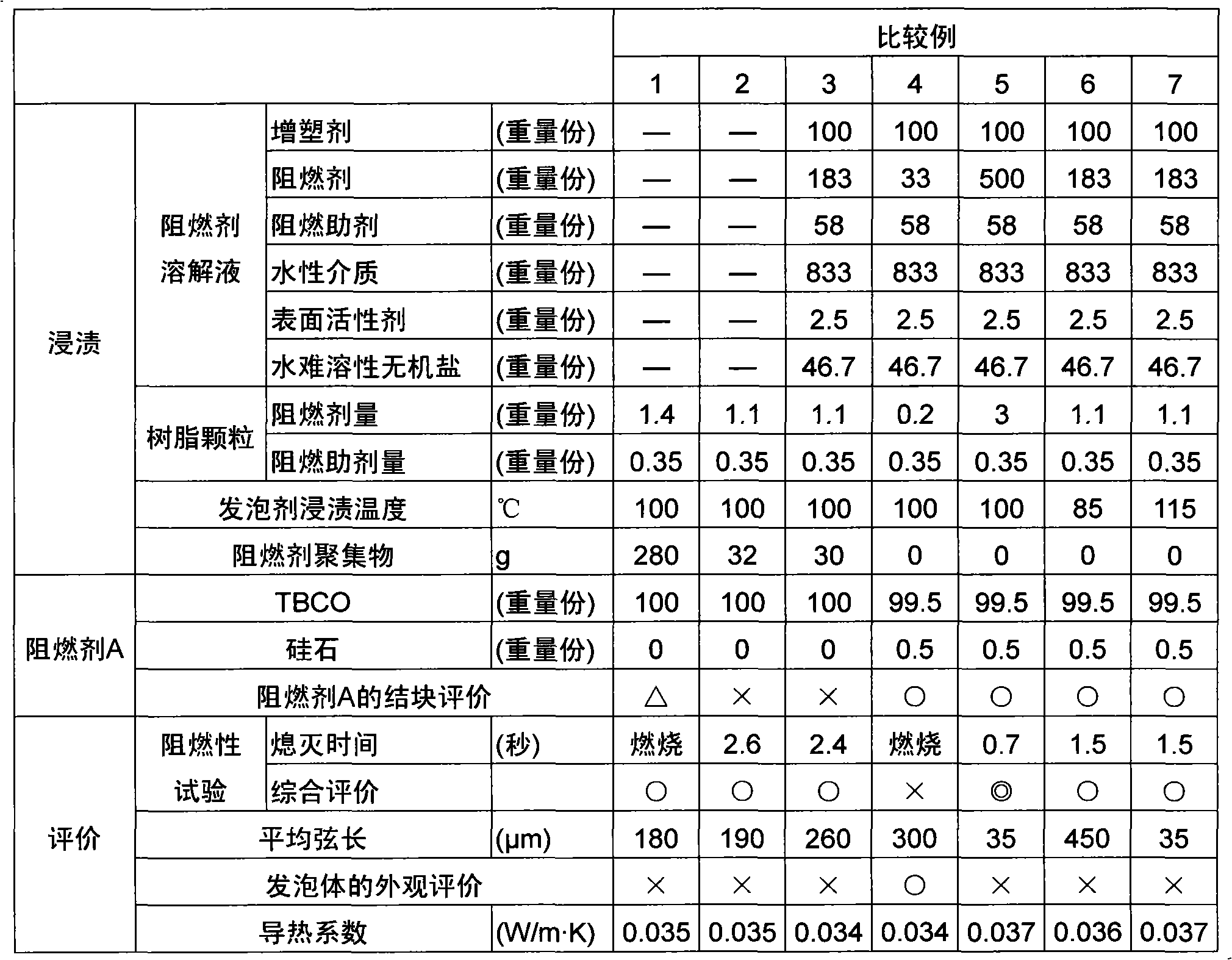

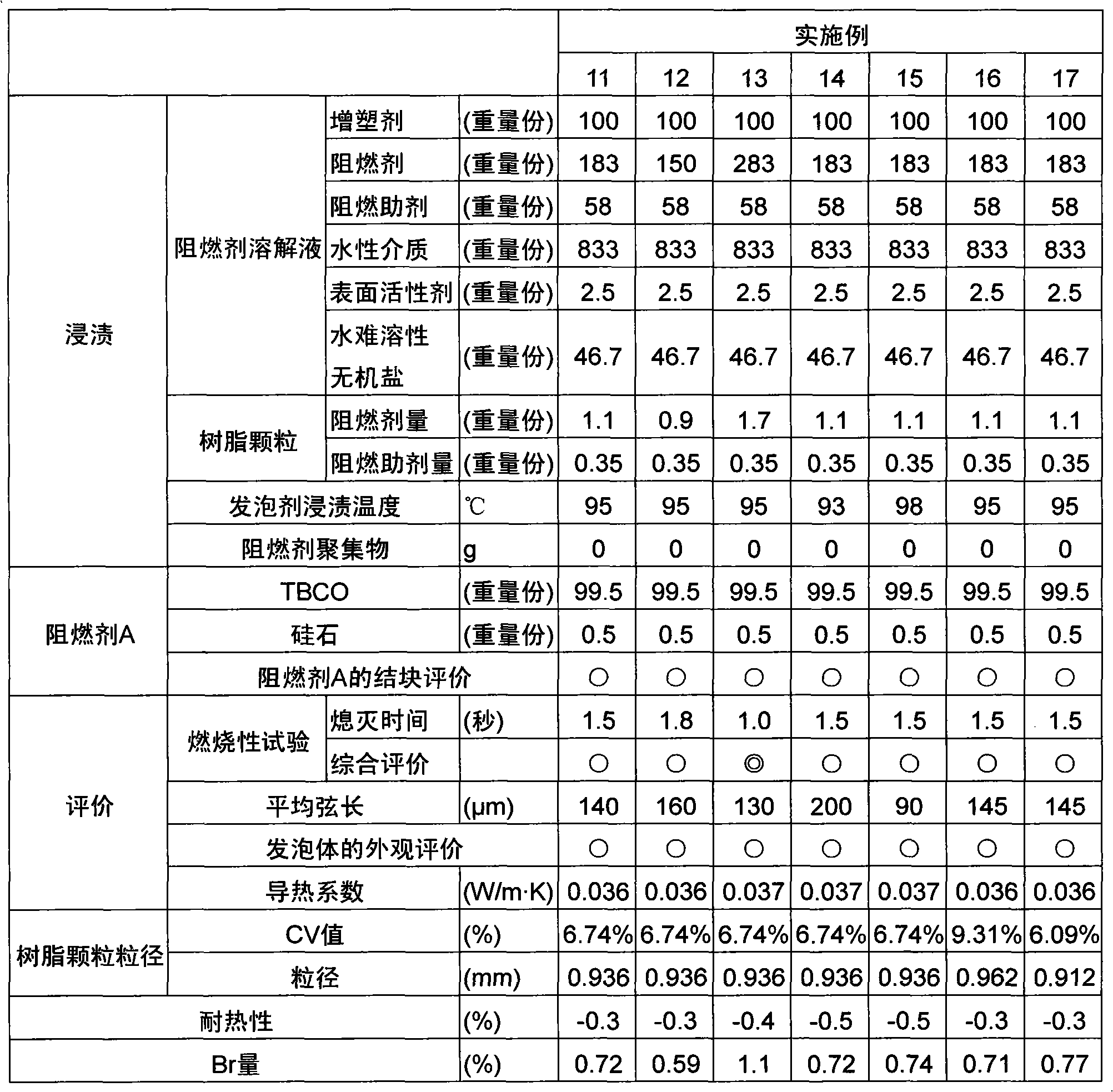

Examples

Embodiment 1

[0145] Supply 120g tricalcium phosphate (manufactured by Daping Chemical Co., Ltd.), 2.4g sodium dodecylbenzenesulfonate, 160g benzoyl peroxide (purity 75% by weight), 30g tert-butyl peroxide-2-ethylhexyl monocarbonate, 40 kg of ion-exchanged water, and 40 kg of styrene monomer were stirred by rotating the stirring blade at a rotation speed of 100 rpm to form an aqueous suspension.

[0146] Then, while the stirring blade was rotated at a rotational speed of 100 rpm to stir the aqueous suspension, the temperature in the autoclave was raised to 90° C. and kept at 90° C. for 6 hours, and the temperature in the autoclave was further raised to 120° C. °C and kept at 120 °C for 2 hours, so that the suspension polymerization of styrene monomer was carried out.

[0147] Then, cool the temperature in the autoclave to 25°C, take out the polystyrene particles from the autoclave, repeat washing and dehydration several times, and after the drying process, classify the polystyrene particles...

Embodiment 2

[0157] 6 g of sodium dodecylbenzenesulfonate and 112 g of magnesium pyrophosphate obtained by the double decomposition method were supplied to 2 kg of ion-exchanged water and stirred, then heated to 50° C. and maintained, while adding 240 g of styrene and 440 g of terrazzo to the above-mentioned ion-exchanged water. Flame retardant A and 140g flame retardant auxiliary agent dicumyl peroxide, use a homomixer (manufactured by Special Machine Chemical Industry Co., Ltd., T.K.Homomixer MARKII fmodel) to stir for 30 minutes at 7000rpm to make flame retardant A and flame retardant auxiliary The flame retardant is completely dissolved therein to form a flame retardant solution, and the flame retardant solution is dispersed in ion-exchanged water to form a dispersion of the flame retardant solution. Next, expandable polystyrene particles were obtained in the same manner as in Example 1, except that the dispersion of the obtained flame retardant solution was supplied into the autoclave ...

Embodiment 3

[0159] Except having changed the flame retardant A to 360 g instead of 440 g, it carried out similarly to Example 2, and obtained the expandable polystyrene-type particle|grains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com