Light source module and adhesive component thereof

An optical component and component technology, which is applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of variation in luminous brightness and chromaticity of phosphor powder distribution, and high manufacturing costs, so as to promote cost reduction, increase photoelectric conversion rate, increase effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

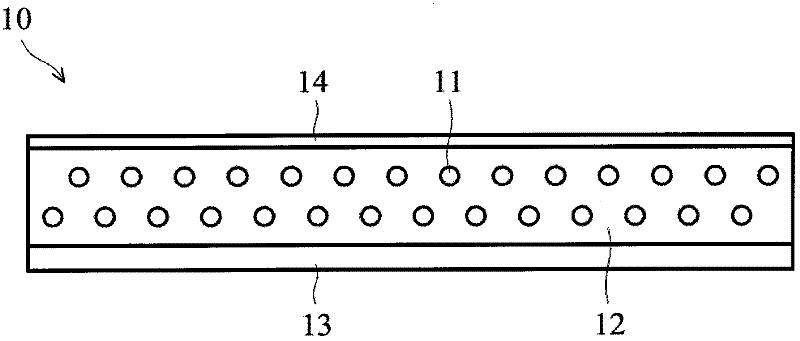

[0047] See first figure 1 , the adhesive member 10 according to an embodiment of the present invention can be set in a light source module, which mainly includes phosphor powder 11 , a glue 12 , a first outer layer 13 and a second outer layer 14 . In this embodiment, the first outer layer 13 is a transparent material, the second outer layer 14 is a release film, and the colloid 12 is located between the first and second outer layers 13, 14. Meanwhile, the phosphor powder 11 is evenly distributed in the colloid 12 . It should be understood that a light source (such as a blue light emitting diode chip) in the light source module can emit light and interact with the fluorescent powder 11 in the colloid 12, so that the light can produce a predetermined color (such as white light ).

[0048] For example, the colloid 12 may contain acrylic, pressure sensitive adhesive (Pressure Sensitive Adhesive, PSA) or optical clear adhesive (Optical Clear Adhesive, OCA) and other materials. In...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap