Through silicon hole structure with step and manufacture process of through silicon hole

A preparation process and technology of through-silicon vias, which are applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as different protrusion heights, different plating rates, and scrapped silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A typical method of carrying out the invention will now be described with reference to the accompanying drawings.

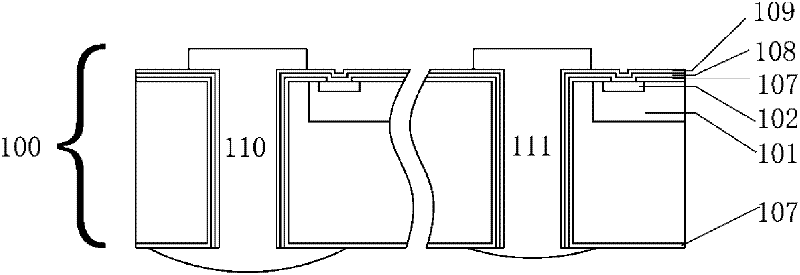

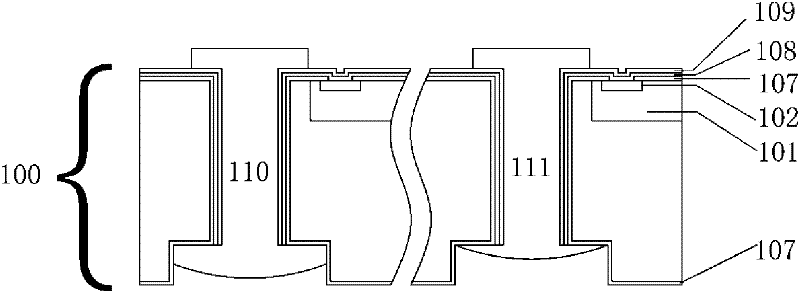

[0027] Such as figure 2 As shown, the structure includes a semiconductor silicon substrate 100 with an integrated circuit 101 (details not shown), integrated circuit pads 102, and two TSV structures formed in the substrate 100 with steps. The TSV structure includes an insulating layer SiO2 107 deposited on the sidewall of the via, a Ti adhesion barrier layer 108 , a copper seed layer 109 , and filling metal copper 110 , 111 . Portions of the copper seed layer 109 on the upper surface of the substrate 100 also serve as lateral interconnects connecting the integrated circuit pads 102 to the fill metal 110 . The copper seed metal layer 109 on the upper surface of the substrate 100 is well bonded to the insulating layer 107 on the substrate through the adhesion barrier layer 108 .

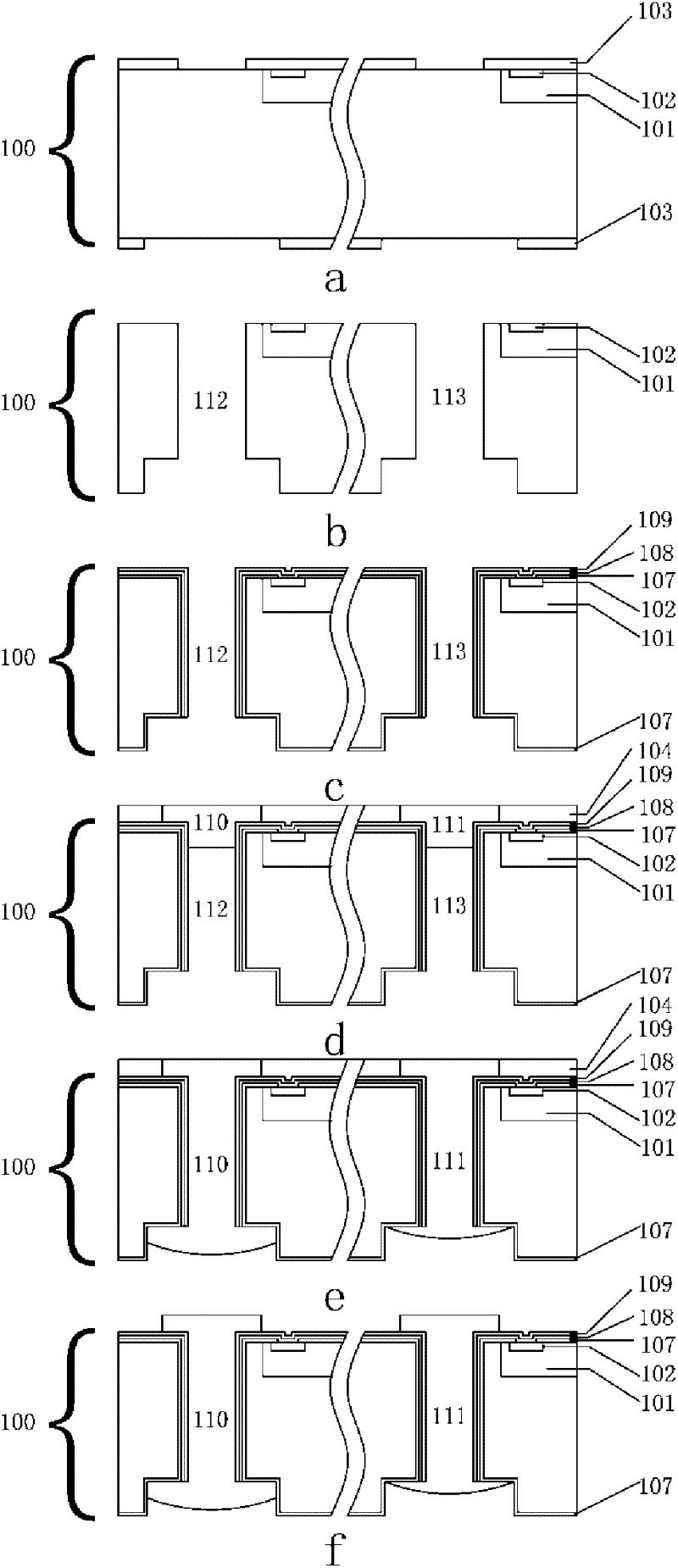

[0028] image 3 A schematic diagram of a typical method for fabricating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com