Dibutyl phthalate molecularly imprinted polymer (DBP-MIP) and preparation method thereof

A technology of dibutyl phthalate and molecular dibutyl phthalate, which is applied in the field of analytical chemistry and can solve the problems of poor specificity of adsorbent and interference detection of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

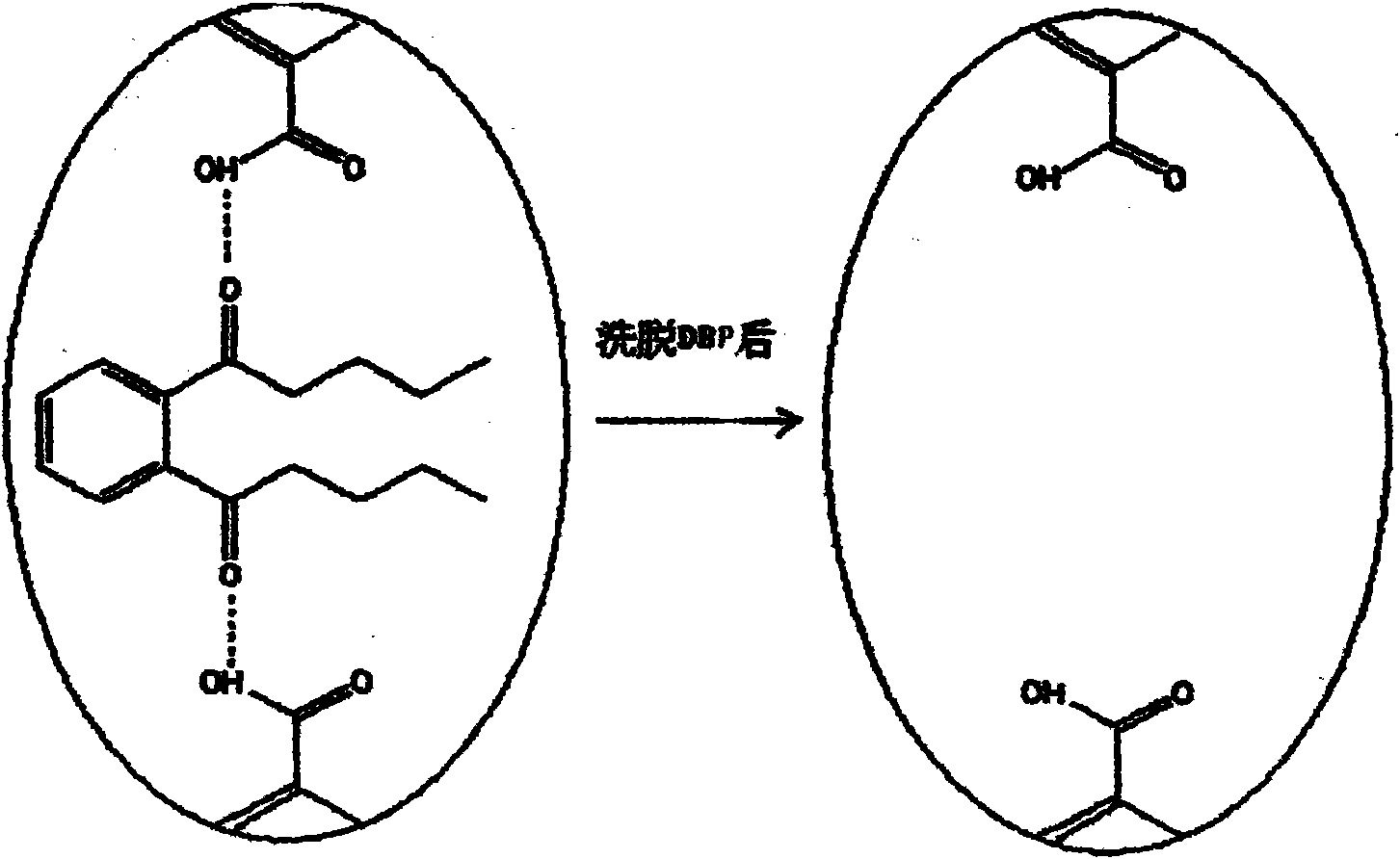

[0028] (1) Synthesis of dibutyl phthalate molecularly imprinted polymer

[0029] (1) Dissolve 0.5mmol of DBP, 2mmol of MMA, 10mmol of EDMA, and 0.05mmol of AIBN in 20mmol of acetonitrile, put the mixed solution in a round-bottomed flask, pre-act 0.5h in an ice-water bath (ultrasonic wave makes various reactants fully mixed Uniform, ice-water bath prevents various reactants from being heated and polymerized in advance during the ultrasonic process, this step is a routine operation method in the laboratory);

[0030] (2) Introduce nitrogen gas for 10 minutes, seal with a rubber stopper, and react in an oil bath at 60° C. for 24 hours to obtain a reaction product. After the reaction, the polymer is ground, sieved, and rinsed with acetone to remove fine particles to obtain a polymer with a particle size of 20-200 μm;

[0031] (3) Use 200 mL of methanol solution containing 10% acetic acid as the extraction agent, perform Soxhlet extraction for 24 hours to remove template molecules...

Embodiment 2

[0041] (1) Synthesis of dibutyl phthalate molecularly imprinted polymer

[0042] (1) Dissolve 0.5mmol of DBP, 2mmol of MMA, 10mmol of EDMA, and 0.05mmol of AIBN in 20mmol of chloroform, put the mixture in a round-bottomed flask, and ultrasonically pre-act for 0.5h in an ice-water bath;

[0043] (2) Introduce nitrogen gas for 10 minutes, seal with a rubber stopper, and react in an oil bath at 60° C. for 24 hours to obtain a reaction product. After the reaction, the polymer is ground, sieved, and rinsed with acetone to remove fine particles to obtain a polymer with a particle size of 20-200 μm;

[0044] (3) Use 200 mL of methanol solution containing 10% acetic acid as the extraction agent, perform Soxhlet extraction for 24 hours to remove template molecules, add the extraction agent once at about 12 hours in the middle, and use 100 mL of methanol to wash after the extraction to remove residual formic acid;

[0045] (4) The molecularly imprinted polymer from which template molecul...

Embodiment 3

[0052] (1) Synthesis of dibutyl phthalate molecularly imprinted polymer

[0053] (1) Dissolve 0.5mmol of DBP, 2mmol of MMA, 10mmol of EDMA, and 0.05mmol of AIBN in 20mmol of acetonitrile, put the mixture in a round-bottomed flask, and pre-act for 0.5h in an ice-water bath;

[0054] (2) Introduce nitrogen gas for 10 minutes, seal with a rubber stopper, and react in an oil bath at 70° C. for 48 hours to obtain a reaction product. After the reaction, the polymer is ground, sieved, and rinsed with acetone to remove fine particles to obtain a polymer with a particle size of 20-200 μm;

[0055] (3) Use 200 mL of methanol solution containing 5% acetic acid as the extractant, perform Soxhlet extraction for 48 hours to remove template molecules, add the extractant once every 12 hours, and wash with 100 mL of methanol to remove residual formic acid after the extraction;

[0056] (4) The molecularly imprinted polymer from which template molecules have been removed is vacuum-dried at 70°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com