Composition for reducing discharge of NOx in regeneration flue gas of fluid catalytic cracking (FCC)

A technology for regenerating flue gas and composition, applied in the direction of chemical/physical process, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of high yield of dry gas and coke, poor performance High-level problems, achieve high conversion rate, low coke and dry gas yield, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of the composition provided by the present invention comprises the following steps: preparing a composition slurry containing macroporous pseudo-boehmite and a rare earth element component, spray-drying the composition slurry and roasting to obtain composition particles, and then mixing with Solution contact impregnation containing IIA, IIB, IVB and VIB group non-noble metal element compounds, and then roasting to obtain the described reduction of FCC regeneration flue gas NO x The discharged composition; a part of which is selected from IIA, IIB, IVB and VIB group non-noble metal element compounds can be introduced into the composition slurry before spray drying. When the prepared composition also contains a metal additive component, the additive is introduced during the preparation of the composition slurry containing the macroporous pseudo-boehmite and the rare earth element component or introduced into the composition particles by impregnation ....

Embodiment 1

[0031] This embodiment illustrates that the present invention reduces NO x Preparation of Emission Composition S1.

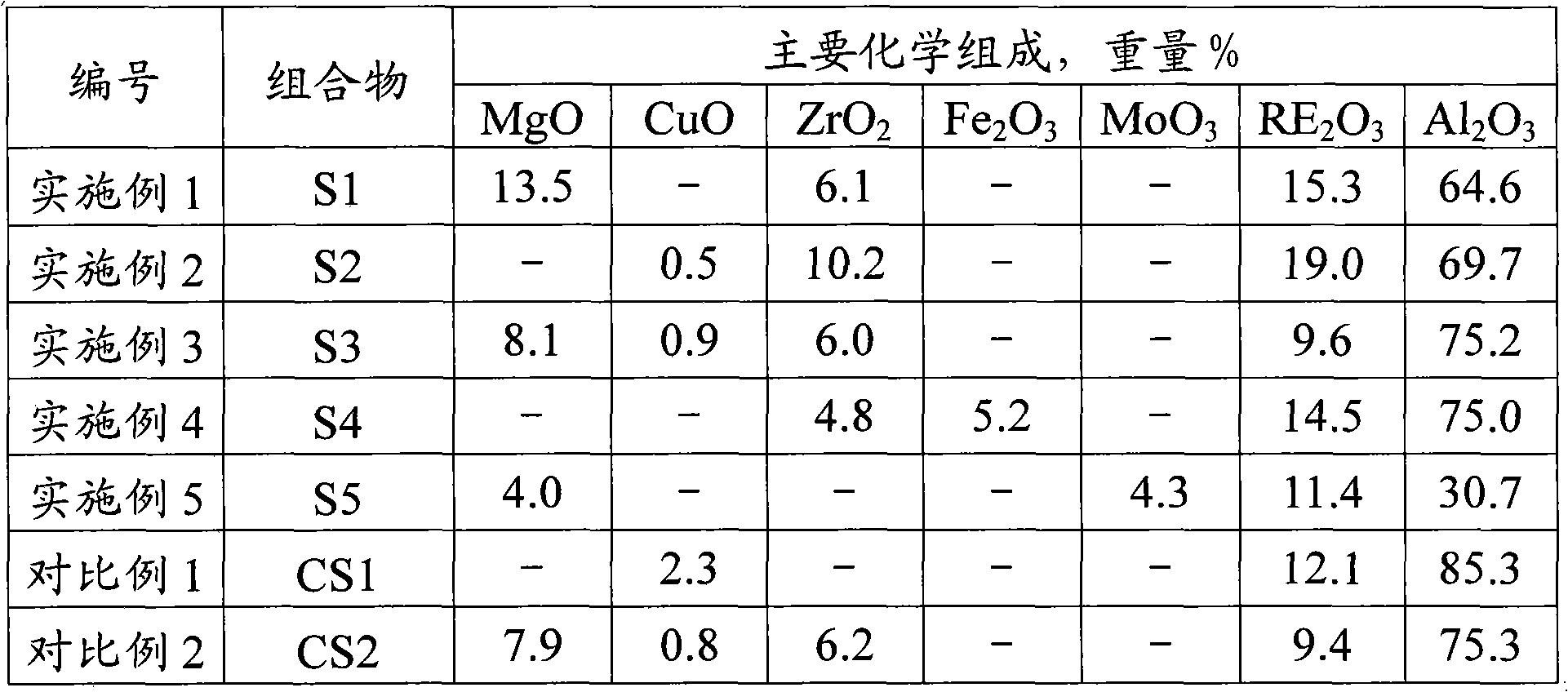

[0032] Based on the weight of oxides, the composition contains 65% by weight of alumina (30% by weight of alumina derived from conventional pseudo-boehmite, 30% by weight of alumina derived from macroporous pseudo-boehmite, Aluminum oxide derived from aluminum sol is 5% by weight), magnesium oxide is 14% by weight, zirconia (as ZrO 2 Meter) 6% by weight, cerium oxide (as CeO 2 Total) 15% by weight.

[0033]Take by weighing 1.48 kilograms of conventional pseudo-boehmite and 1.23 kilograms of large-pore pseudo-boehmite, add to 7.1 liters of deionized water for beating, then add 1200 milliliters of cerium nitrate aqueous solution that is dissolved with 1135 grams of cerium nitrate, and add 400 milliliters of cerium nitrate under stirring Acidify with dilute hydrochloric acid with a mass concentration of 19.8%, then add 698 grams of aluminum sol, stir evenly, the...

Embodiment 2

[0037] This embodiment illustrates that the present invention reduces NO x Preparation of Emission Composition S2.

[0038] Based on the weight of oxides, the composition contains 70% of alumina (30% by weight of conventional pseudo-boehmite, 40% by weight of macroporous pseudo-boehmite), 0.5% by weight of copper oxide, Zirconia (as ZrO 2 meter) 10% by weight, rare earth oxides (in RE 2 o 3 Total) 19.5% by weight.

[0039] Mix 1.48 kg of conventional pseudo-boehmite and 1.64 kg of macroporous pseudo-boehmite with 7.4 liters of deionized water for beating, add 2170 ml of lanthanum-rich mixed rare earth solution to the resulting slurry and stir, then add 450 ml of lanthanum-rich mixed rare earth solution to a concentration of 19.8 Acidify with weight % dilute hydrochloric acid, stir evenly, spray dry, and roast at 600° C. for 1 hour to obtain carrier M2 for use.

[0040] Weigh 10.6 grams of Zr(NO 3 ) 4 ·5H 2 O and 0.5 g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 36 ml of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com