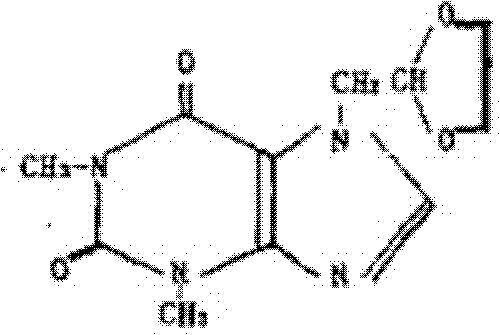

More stable doxofylline compound and pharmaceutical composite thereof

A technology for doxofylline and compound, applied in the field of preparation of pharmaceutical compounds, can solve problems such as more than 0.2%, and achieve the effects of long standing time, high yield and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The doxofylline crude product is dissolved in a mixed solvent of ethyl acetate and methanol=1:2 (v / v) with 8 times its weight, and the gac of about 5% (v / w) weight of the solution volume is added, heated to reflux temperature, continued for 1 hour, placed at room temperature for 24 hours, crystallization was precipitated, crystallization was obtained after suction filtration, and the above steps were repeated to obtain the second recrystallization product, which was washed with ethyl acetate and dried to obtain the pure product of doxofylline. HPLC detection shows that the pure product of doxofylline has a purity of 99.85%, and the content of unknown impurities is less than 0.1%.

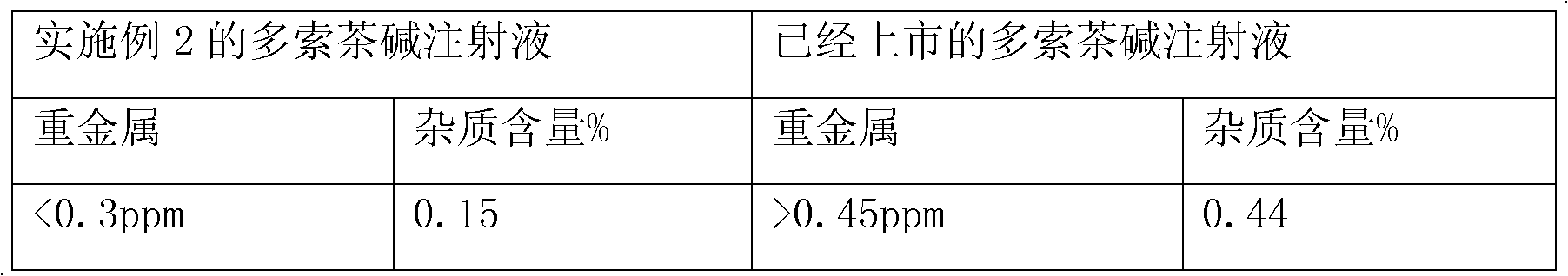

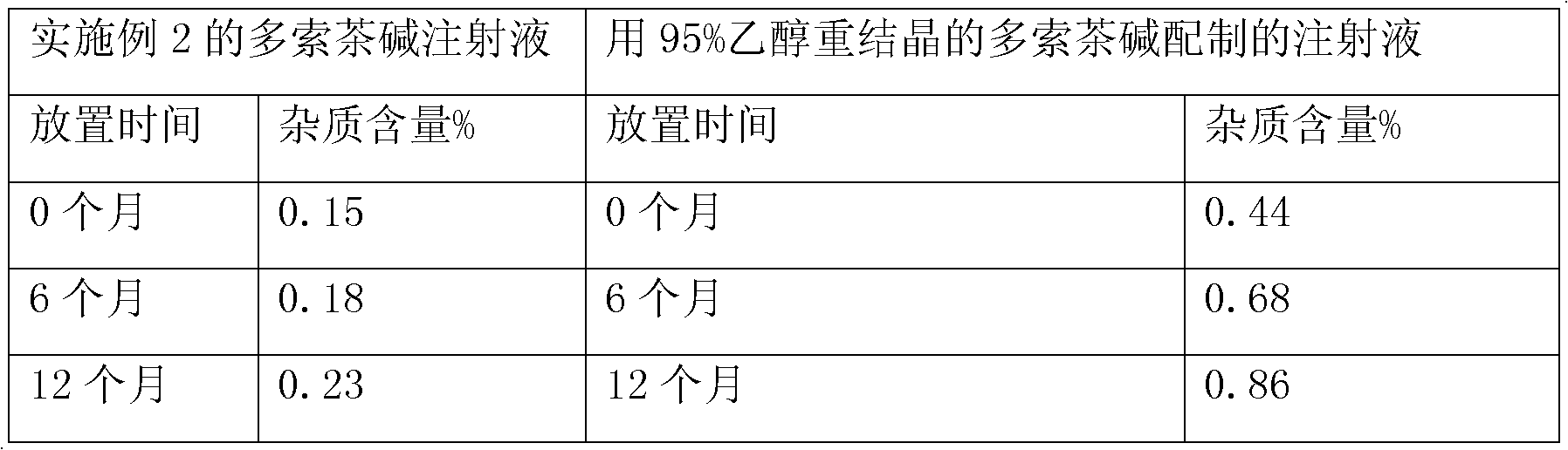

Embodiment 2

[0045] The doxofylline pure product 100g that embodiment 1 obtains

[0047] Edetate Disodium 5g

[0048] PEG-400 50g

[0049] Disodium hydrogen phosphate-sodium dihydrogen phosphate buffer 10L

[0050] Its preparation method is as follows:

[0051] Get doxofylline 100g, mix and grind with PEG-400, dissolve the ground material of doxofylline and PEG-400 with the prepared disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a pH value of 6.5, add 0.5% activated carbon, heated to 80°C and maintained for 15 minutes, filtered to remove carbon, then added sodium bisulfite, disodium edetate, stirred to dissolve, added disodium hydrogen phosphate-sodium dihydrogen phosphate buffer to 10000ml, added 0.5% activated carbon, boiled, finely filtered with a 0.45 μm microporous membrane, and sterilized with a 0.20 μm microporous membrane, canned, sterilized, and labeled.

Embodiment 3

[0053] Doxofylline 100g

[0055] Edetate Disodium 5g

[0056] PEG-400 50g

[0057] Disodium hydrogen phosphate-sodium dihydrogen phosphate buffer 10L

[0058] Its preparation method is as follows:

[0059]Get doxofylline 100g, mix and grind with PEG-400, dissolve the ground material of doxofylline and PEG-400 with the prepared disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a pH value of 6.5, add 0.5% activated carbon, heated to 80°C and maintained for 15 minutes, filtered to remove carbon, then added sodium bisulfite, disodium edetate, stirred to dissolve, added disodium hydrogen phosphate-sodium dihydrogen phosphate buffer to 10000ml, added 0.5% activated carbon, boiled, finely filtered with a 0.45 μm microporous membrane, and sterilized with a 0.20 μm microporous membrane, canned, semi-sealed, put into a freeze-drying box, freeze-dried, sealed, Label it and pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com