Leakage coaxial cable of lapped braided outer conductor and production technology thereof

A technology of leaking coaxial cables and outer conductors, applied in the directions of waveguides, circuits, electrical components, etc., can solve the problems that the bending performance cannot meet the requirements of mine use, the frequency of application is not wide, and the weight of the cable is large, and the frequency of use can be increased. Wide range, low price and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

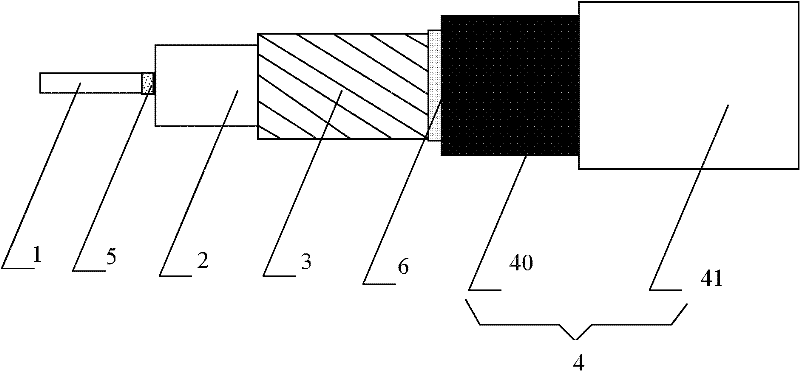

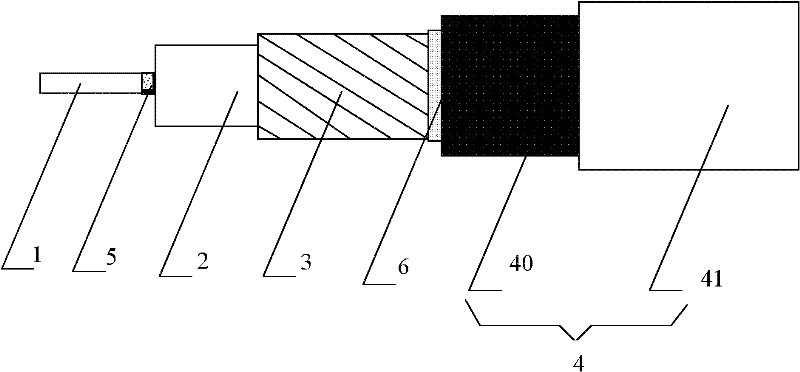

[0030] Such as figure 1 As shown, a leaky coaxial cable with a braided outer conductor is composed of an inner conductor 1, an insulating layer 2, an outer conductor 3 and an outer layer 4 from the inside to the outside to form a multi-layer structure; the inner conductor 1 and the insulation There is also an inner thin layer 5 for bonding the inner conductor 1 and the insulating layer 2 between the layers 2 and has a waterproof and moisture-proof effect; the outer layer 4 is composed of an inner sheath 40 and an outer sheath 41 of a double-layer structure, The inner sheath 40 is made by continuous closed extrusion of a weather-resistant polymer sheath material, and the outer sheath 41 is made by continuous closed extrusion of a flame-retardant polymer sheath material; the inner sheath of the outer layer 4 40 and the outer conductor 3 are also provided with a water-blocking layer 6 that is smoothly wrapped on the outer conductor 3 by a thin layer of polyester film or water-blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com