Pretreatment method of polymer bonded explosive sample

A technology of bonding explosives and polymers, which is applied in the field of explosives and can solve the problems that ultrasonic extraction technology cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

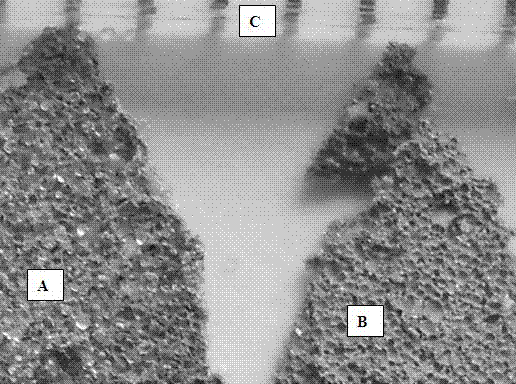

Image

Examples

Embodiment Construction

[0022] According to the technical scheme of the present invention, the pretreatment method of the high polymer bonded explosive sample of the present invention comprises the following steps:

[0023] Step 1, processing the same batch of high polymer bonded explosive samples into sample blocks of suitable size;

[0024] Step 2, weighing 0.5000 g of the prepared sample block, and adding it to a stoppered glass container;

[0025] Step 3, measure 30mL of acetone, and add it into the above-mentioned stoppered glass container;

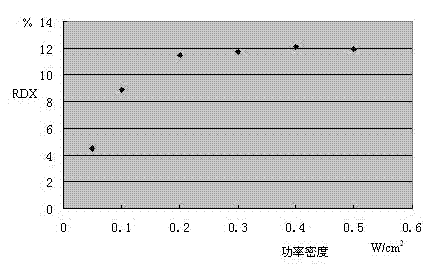

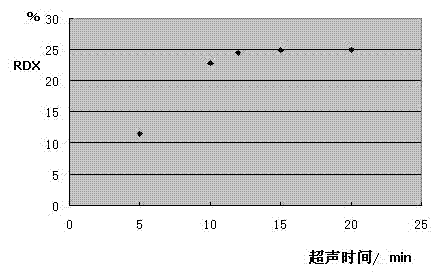

[0026] Step 4, place the stoppered glass container containing the sample and acetone in the ultrasonic instrument, and adjust the power density to not less than 0.2W / cm 2 , not higher than 0.5W / cm 2 , ultrasonic extraction for 15min to 20min;

[0027] Step 5: After the ultrasonic extraction is completed, take out the stoppered glass container to obtain the sample solution; the next step of analyzing the RDX content in the polymer bonded explosive compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com