Hydrophobic nano composite automobile finish and preparation method thereof

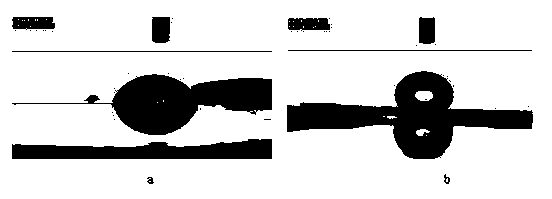

An automotive topcoat and nano-composite technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of unpopular production, poor coating durability, and need for regular replacement, and achieve good mechanical properties, good adhesion, and save on car washing Effects of Water Use and Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

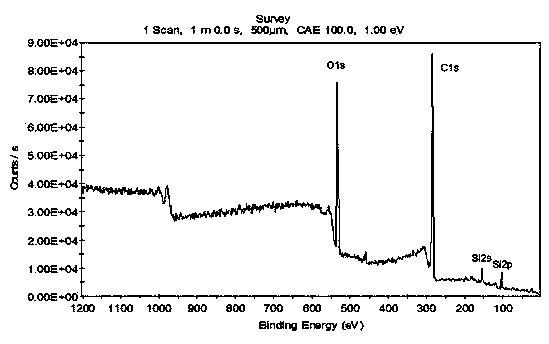

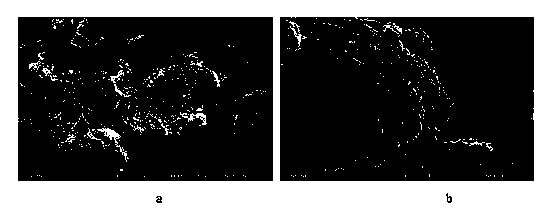

[0023] Put 20g of 3-triethoxysilyl-1-propylamine into the reaction kettle, add 200g ethyl acetate and 170g xylene, stir for 30 minutes (rotational speed is 600 rpm), keep stirring, then add 50g of nano-silica to obtain a nano-silica dispersion; use an ultrasonic nano-material disperser to disperse for 30 minutes at a temperature of 45° C. and an ultrasonic frequency of 30 kHz.

[0024] Add 500g of car topcoat (selected from Reiz Acrylic Car Paint 2k52) into the reactor, control the temperature at 35°C, and stir for 1.5 hours (rotational speed is 400 rpm) to make it fully mixed and the state is uniform and stable. Put the mixed solution in an ultrasonic disperser, disperse with ultrasonic for 60 minutes, at a temperature of 45° C., and an ultrasonic frequency of 30 kHz, and remove the solvent by suction filtration to obtain the hydrophobic topcoat of the present invention.

Embodiment 2

[0026] Put 20g of γ-glycidoxypropyltrimethoxysilane into the reaction kettle, add 400g ethyl acetate, stir for 40 minutes (rotation speed is 400 rpm), keep stirring, then add 50 nanometer silica , To obtain a nano-silica dispersion. Use an ultrasonic nano-material disperser to disperse for 20 minutes at a temperature of 30°C and an ultrasonic frequency of 40 kHz.

[0027] Add 500g of car topcoat (selected from Reiz acrylic type car paint RZ9000) into the reaction kettle, control the temperature at 30°C, and stir for 1 hour (rotational speed is 800 rpm) to make it fully mixed and the state is uniform and stable. Put the mixed solution in an ultrasonic disperser, disperse by ultrasonic for 45 minutes, at a temperature of 30° C., and an ultrasonic frequency of 40 kHz, and remove the solvent by suction filtration to obtain the hydrophobic topcoat of the present invention.

Embodiment 3

[0029] Put 50g of 3-triethoxysilyl-1-propylamine into the reaction kettle, add 500g of xylene, stir for 20 minutes (rotational speed is 800 rpm), keep stirring, then add 55g of nano silica , Obtain the nano-silica dispersion liquid; use an ultrasonic nano-material disperser, disperse for 40 minutes, the temperature is 55 DEG C, the ultrasonic frequency is 20 kHz.

[0030] Add 600g of car topcoat (selected from Reiz Acrylic Car Paint 1KS22B) into the reactor, control the temperature at 40°C, and stir for 2 hours (rotational speed is 300 rpm) to make it fully mixed and the state is uniform and stable. Put the mixed solution in an ultrasonic disperser, disperse with ultrasonic for 90 minutes, at a temperature of 55° C., and an ultrasonic frequency of 20 kHz, and remove the solvent by suction filtration to obtain the hydrophobic topcoat of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com