Preparation method of ceramic wiper plate

A technology for wiper blades and ceramics, which is applied in the field of preparation of ceramic wiper blades, can solve the problems of low hardness of alumina materials, unstable product performance, and uneven seams, so as to achieve precise dimensions and avoid seams Uneven, uniform microstructure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

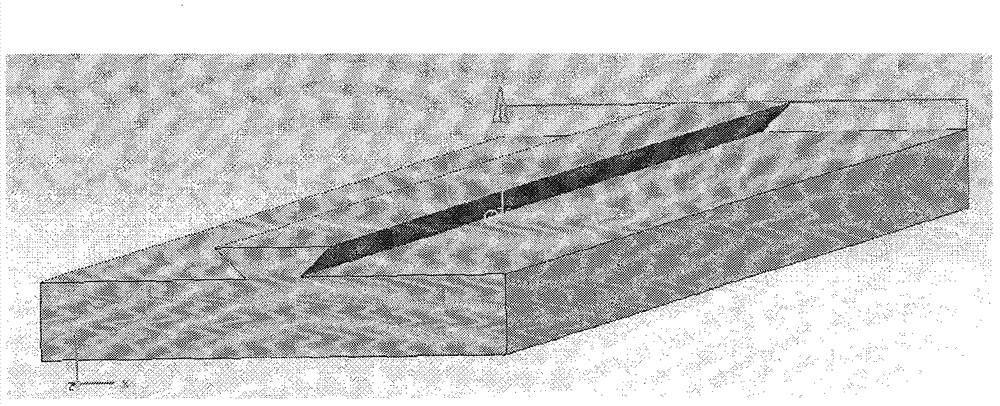

Image

Examples

Embodiment 1

[0011] 1. Forming of extrusion molding body

[0012] Mix silicon carbide powder with a particle size of 0.3 μm, graphite powder with a particle size of 0.3 μm, carbon black with a particle size of 0.5 μm, phenolic resin and liquid paraffin in a weight ratio of 30:20:20:20:10 in a vacuum mud mixer The silicon carbide ceramic plastic mud is made by kneading in the medium, and the above mud is extruded and cut into an extruded body.

[0013] 2. Curing:

[0014] The extruded blank was cured at 90° C. for 8 hours to make a ceramic wiper blank.

[0015] 3. Firing:

[0016] The cured ceramic wiper blade body is fired at room temperature to 100°C for 4 hours, at 100 to 300°C for 10 hours, at 300°C for 8 hours, at a firing temperature of 1500°C, and for 4 hours in a nitrogen atmosphere , and then polished to make ceramic wipers.

[0017] The purity of the batching raw materials used in the experiment is industrial pure.

[0018] The compressive strength of the obtained extruded ce...

Embodiment 2

[0020] 1. Forming of extrusion molding body

[0021] Mix silicon carbide powder with a particle size of 0.1 μm, graphite powder with a particle size of 0.5 μm, carbon black with a particle size of 0.3 μm, phenolic resin and liquid paraffin in a weight ratio of 55:11:11:15:8 in a vacuum mud mixer The silicon carbide ceramic plastic mud is made by kneading in the medium, and the above mud is extruded and cut into an extruded body.

[0022] 2. Curing:

[0023] The extruded blank was cured at 70° C. for 9 hours to make a ceramic wiper blank.

[0024] 3. Firing:

[0025] The cured ceramic wiper blade body is fired at room temperature to 100°C for 5 hours, at 100 to 300°C for 13 hours, at 300°C for 10 hours, at a firing temperature of 1800°C, and for 3 hours in a nitrogen atmosphere , and then polished to make ceramic wipers.

[0026] The purity of the batching raw materials used in the experiment is industrial pure.

[0027] The compressive strength of the obtained extruded ce...

Embodiment 3

[0029] 1. Forming of extrusion molding body

[0030] Mix silicon carbide powder with a particle size of 0.5 μm, graphite powder with a particle size of 0.1 μm, carbon black with a particle size of 0.1 μm, phenolic resin and liquid paraffin at a weight ratio of 80:2:3:10:5 in a vacuum mud mixer The silicon carbide ceramic plastic mud is made by kneading in the medium, and the above mud is extruded and cut into an extruded body.

[0031] 2. Curing:

[0032] The extruded green body was cured at 50° C. for 10 hours to make a ceramic wiper blade green body.

[0033] 3. Firing:

[0034] The cured ceramic wiper blade body is fired at room temperature to 100°C for 6 hours, at 100 to 300°C for 16 hours, at 300°C for 12 hours, at a firing temperature of 2000°C, for 2 hours in a nitrogen atmosphere , and then polished to make ceramic wipers.

[0035] The purity of the batching raw materials used in the experiment is industrial pure.

[0036] The compressive strength of the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com