Continuous uniform rotating illumination device for surface treatment of rubber rollers

A technology for surface treatment and lighting device, applied in the field of continuous and uniform rotating lighting device, can solve the problems of high cost, complicated process, unstable product quality, etc., and achieve the effects of simple operation, uniform illumination and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

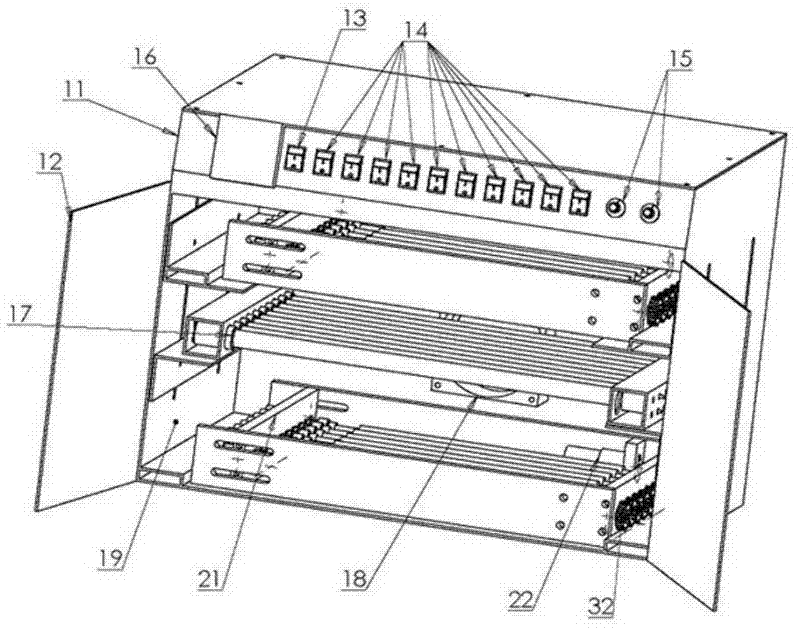

[0018] see figure 1 , The present invention is used for the device of ultraviolet light treatment on the surface of rubber roller, adopts box structure, is made up of box casing 11, light source 17, rubber roller rotating support 21, electrical control part and fan 18 etc.

[0019] Wherein the electrical control part includes switches 13 and 14, a timer 16, a governor 15, and a motor 22.

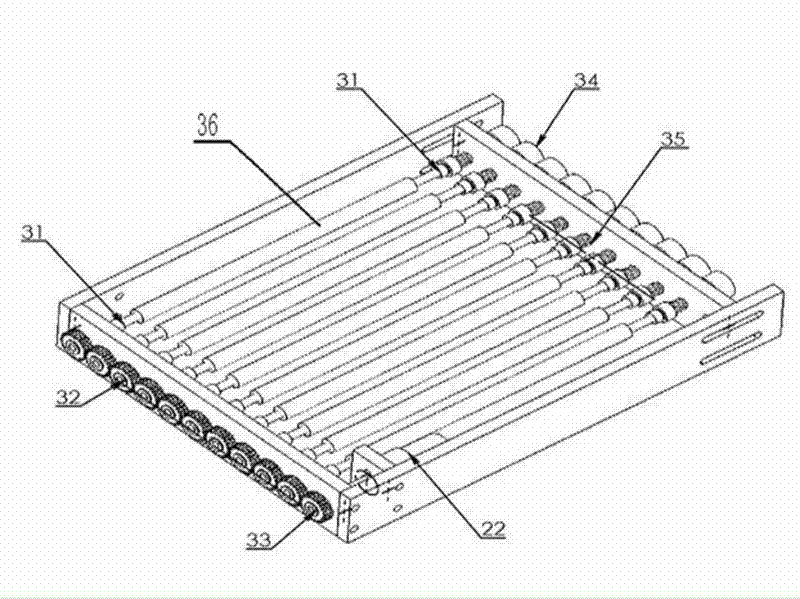

[0020] Switch 13 and 14, timer 16, governor 15 are installed on the upper part of the front side of the casing, and the bottom is the box door 12; the fan 18 is installed in the air outlet in the middle part of the rear side of the casing. The rubber roller rotating bracket 21 is installed inside the casing, and the motor 22 is installed on one end of the rubber roller rotating bracket 21, and is used to drive each rubber roller installed in the rubber roller rotating bracket 21 to rotate when in use. Paste aluminum foil 19 on the inner wall of the shell. The light source 17 adopts a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com