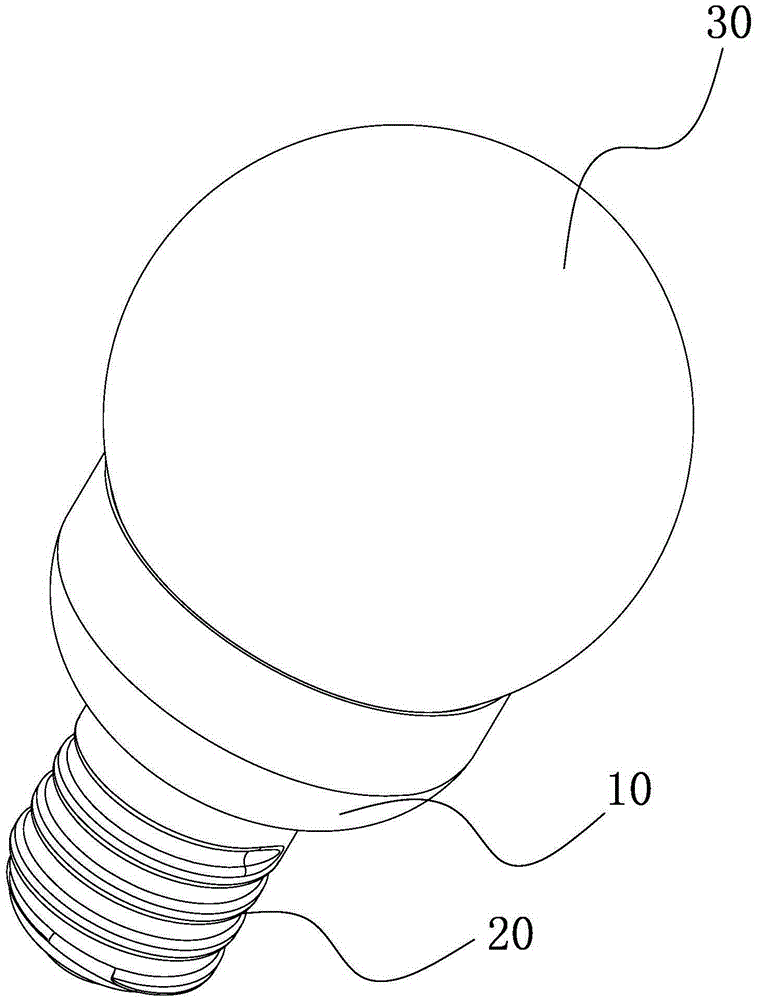

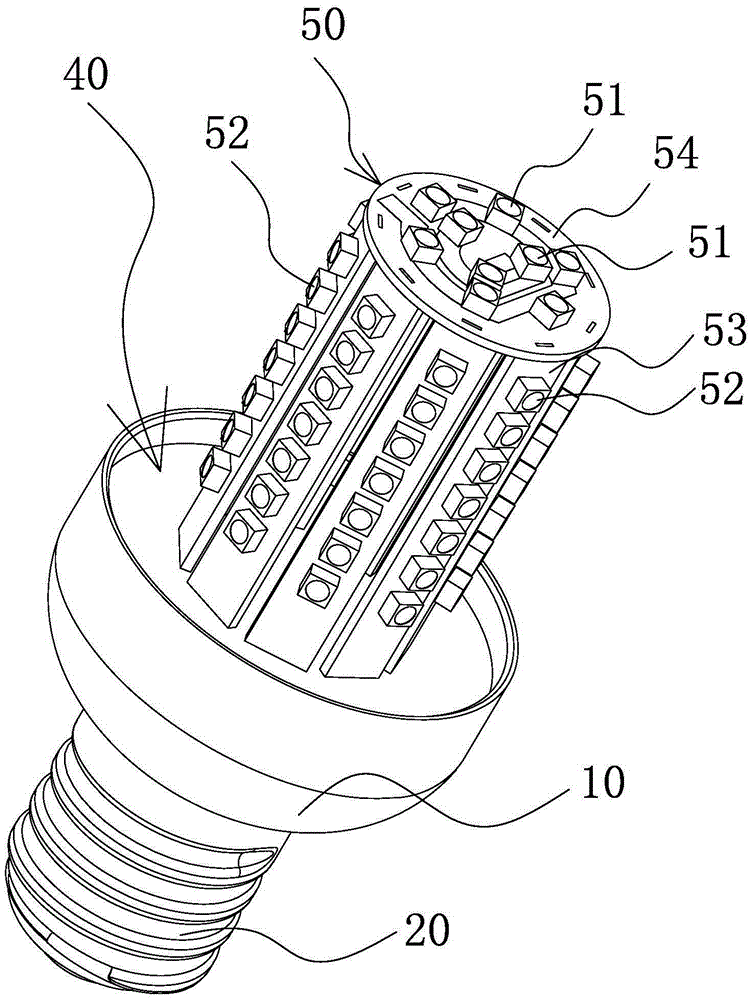

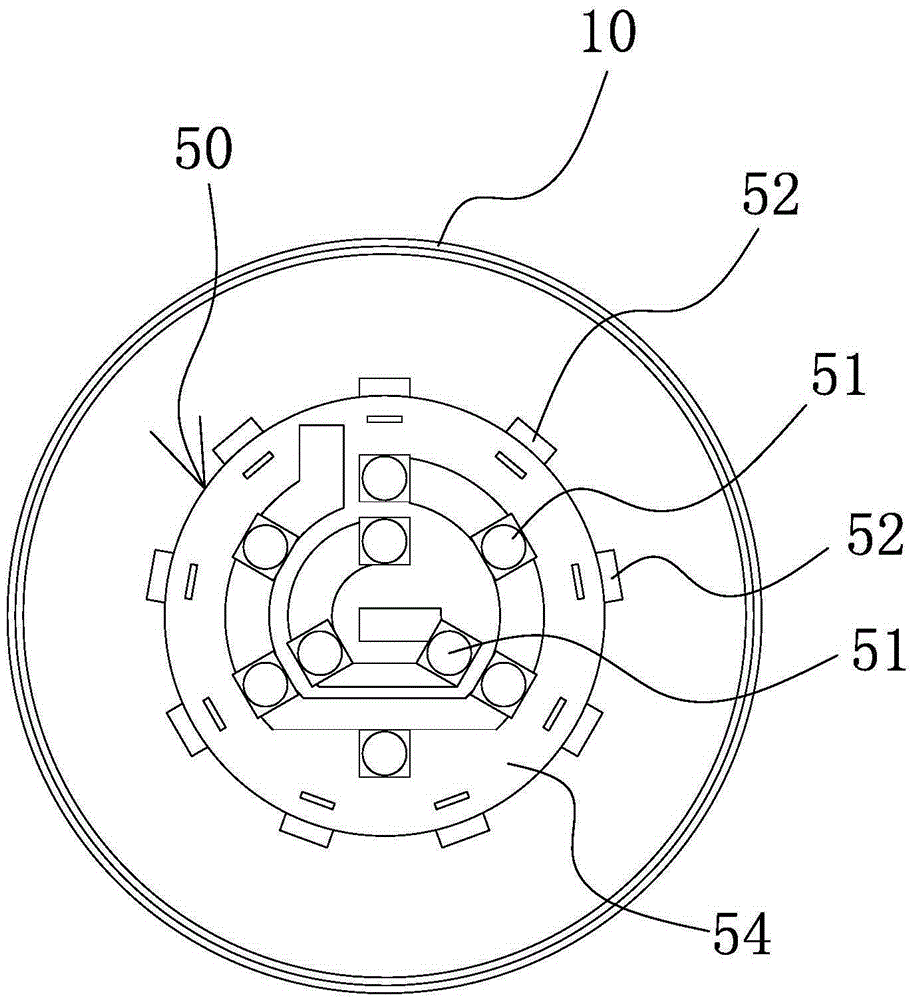

Improved bulb light

A bulb lamp and an improved technology, applied in the field of lighting, can solve problems such as unsatisfactory lighting effects, inability to meet the needs of high-quality life, etc., to achieve ideal lighting effects, reduce stacking and staggered phenomena, and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The tin bronze alloy is composed of the following parts by weight: Sn: 10 parts, P: 15 parts, Zn: 10 parts, Al: 0.03 parts, PbS: 5.5 parts, B: 1 part, Ce: 0.20 parts, Cu: 85 parts .

[0090] Put the above raw materials into the crucible, heat rapidly to 1400°C for smelting, keep it warm for 25 minutes to fully dissolve the alloy; cast the smelted alloy, and extrude the alloy at a temperature of 900°C and a holding time of 75 minutes; then the alloy Carry out cold deformation processing; then, at a temperature of 360°C, the alloy is annealed multiple times; finally, the alloy is stretched and the stretched finished product is passivated for 30s.

Embodiment 2

[0092] The tin bronze alloy is composed of the following parts by weight: Sn: 20 parts, P: 10 parts, Zn: 5 parts, Al: 0.06 parts, PbS: 3.5 parts, B: 0.2 parts, Ce: 0.45 parts, Cu: 95 parts .

[0093] Put the above raw materials into the crucible, heat rapidly to 1500°C for smelting, and keep it warm for 30 minutes to fully dissolve the alloy; cast the smelted alloy into a slab, and extrude the alloy at a temperature of 920°C and a holding time of 85 minutes; then the alloy Carry out cold deformation processing; then, at a temperature of 360°C, the alloy is annealed multiple times; finally, the alloy is stretched and the stretched finished product is passivated for 60s.

Embodiment 3

[0095] The tin bronze alloy is composed of the following parts by weight: Sn: 15 parts, P: 12 parts, Zn: 7 parts, Al: 0.05 parts, PbS: 4.5 parts, B: 0.6 parts, Ce: 0.35 parts, Cu: 90 parts .

[0096] Put the above-mentioned raw materials into the crucible, heat rapidly to 1480°C for melting, and keep it warm for 28 minutes to fully dissolve the alloy; cast the smelted alloy into a slab, and extrude the alloy at a temperature of 950°C and a holding time of 82 minutes; then the alloy Carry out cold deformation processing; then, at a temperature of 360°C, the alloy is annealed multiple times; finally, the alloy is stretched and the stretched finished product is passivated for 45s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com