Intermediate layer assembly for connecting Si3N4 ceramic and stainless steel and connecting method

A connection method and stainless steel technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low joint strength and large residual stress, and achieve the effect of high connection strength, good wetting performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Selection of middle-level components:

[0026] 1. The purity of Ti foil 2 is 99.7% and the thickness is 10μm;

[0027] 2. The composition and content of Ag-Cu solder foil 3 are as follows by mass percentage: Ag: 72.0%, Cu: 28.0%, and a thickness of 150μm;

[0028] 3. The purity of Ni foil 4 is 99.9% and the thickness is 600μm.

[0029] 2. Connection steps and methods:

[0030] (1) The Si to be connected 3 N 4 The end surface of the ceramic 1 sample was polished with 3.5um diamond paste, and Ti foil 2, Ag-Cu solder foil 3, Ni foil 4 and stainless steel 5 were polished with No. 5 metallographic sandpaper. Then put them together in acetone for ultrasonic cleaning for 10 minutes;

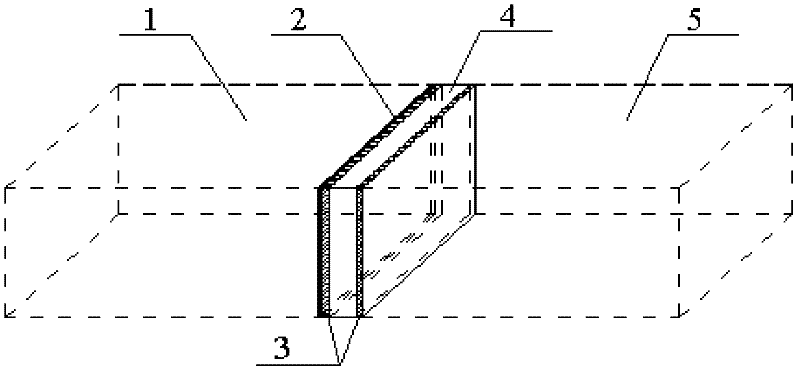

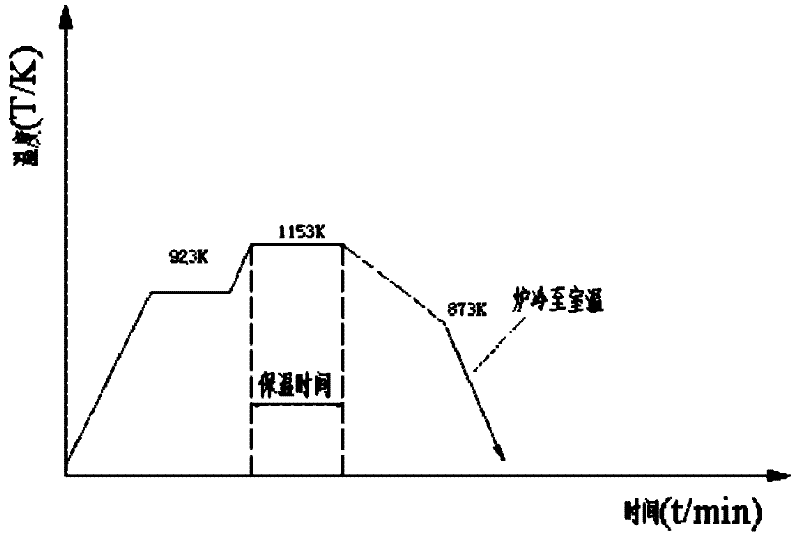

[0031] (2) Combine Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, stainless steel 5 and Si 3 N 4 Ceramic 1 Press Si 3 N 4 The order of ceramic 1, Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, Ag-Cu solder foil 3, and stainless steel 5 are closely mounted in a special fixture, such as figure 1 As shown; at the ...

Embodiment 2

[0035] 1. Selection of middle-level components:

[0036] 1. The purity of Ti foil 2 is 99.7% and the thickness is 5μm;

[0037] 2. The composition and content of the Ag-Cu solder foil 3 are as follows in terms of mass percentage: Ag: 72.0%, Cu: 28.0%, and a thickness of 100 μm;

[0038] 3. The purity of Ni foil is 99.7% and the thickness is 800μm.

[0039] 2. Connection steps and methods:

[0040] (1) The Si to be connected 3 N 4 The end face of the ceramic sample is polished with 3.5um diamond paste, and Ti foil 2, Ag-Cu solder foil 3, Ni foil 4 and stainless steel 5 are polished with No. 5 metallographic sandpaper; then they are placed in acetone for ultrasonic Wash for 10 minutes;

[0041] (2) Combine Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, stainless steel 5 and Si 3 N 4 Ceramic 1 Press Si 3 N 4 The order of ceramic 1, Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, Ag-Cu solder foil 3, and stainless steel 5 are closely mounted in a special fixture, such as figure 1 As shown; at the sa...

Embodiment 3

[0045] 1. Selection of middle-level components:

[0046] 1. The purity of Ti foil 2 is 99.7% and the thickness is 8μm;

[0047] 2. The composition and content of Ag-Cu solder foil 3 are as follows by mass percentage: Ag: 72.0%, Cu: 28.0%, and the thickness is 120μm;

[0048] 3. The purity of Ni foil is 99.7% and the thickness is 600μm.

[0049] 2. Connection steps and methods:

[0050] (1) The Si to be connected 3 N 4 The end face of the ceramic sample is polished with 3.5um diamond paste, and Ti foil 2, Ag-Cu solder foil 3, Ni foil 4 and stainless steel 5 are polished with No. 5 metallographic sandpaper; then they are placed in acetone for ultrasonic Wash for 10 minutes;

[0051] (2) Combine Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, stainless steel 5 and Si 3 N 4 Ceramic 1 Press Si 3 N 4 The order of ceramic 1, Ti foil 2, Ag-Cu solder foil 3, Ni foil 4, Ag-Cu solder foil 3, and stainless steel 5 are closely installed in a special fixture; at the same time, a small weight is placed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com