Guide centering adjustment device

A technology for centering adjustment and guide, applied in the field of rolling equipment, can solve the problems of guide and guide traverse centering deviation, unsatisfactory guide and guide centering rate, batch quality accidents, etc., so as to avoid centering errors and reduce guide and guard. Consumption, the effect of reducing sticking to steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

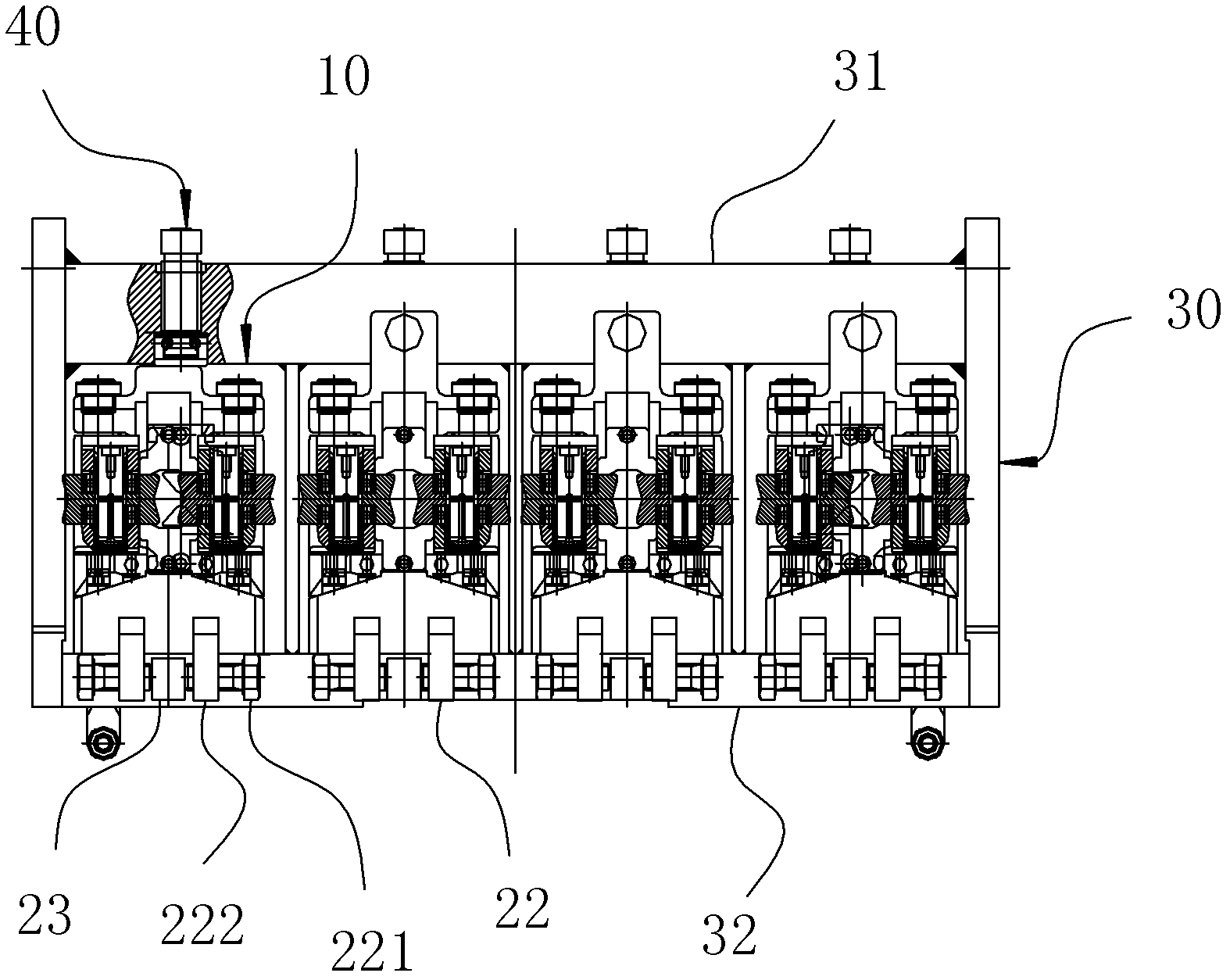

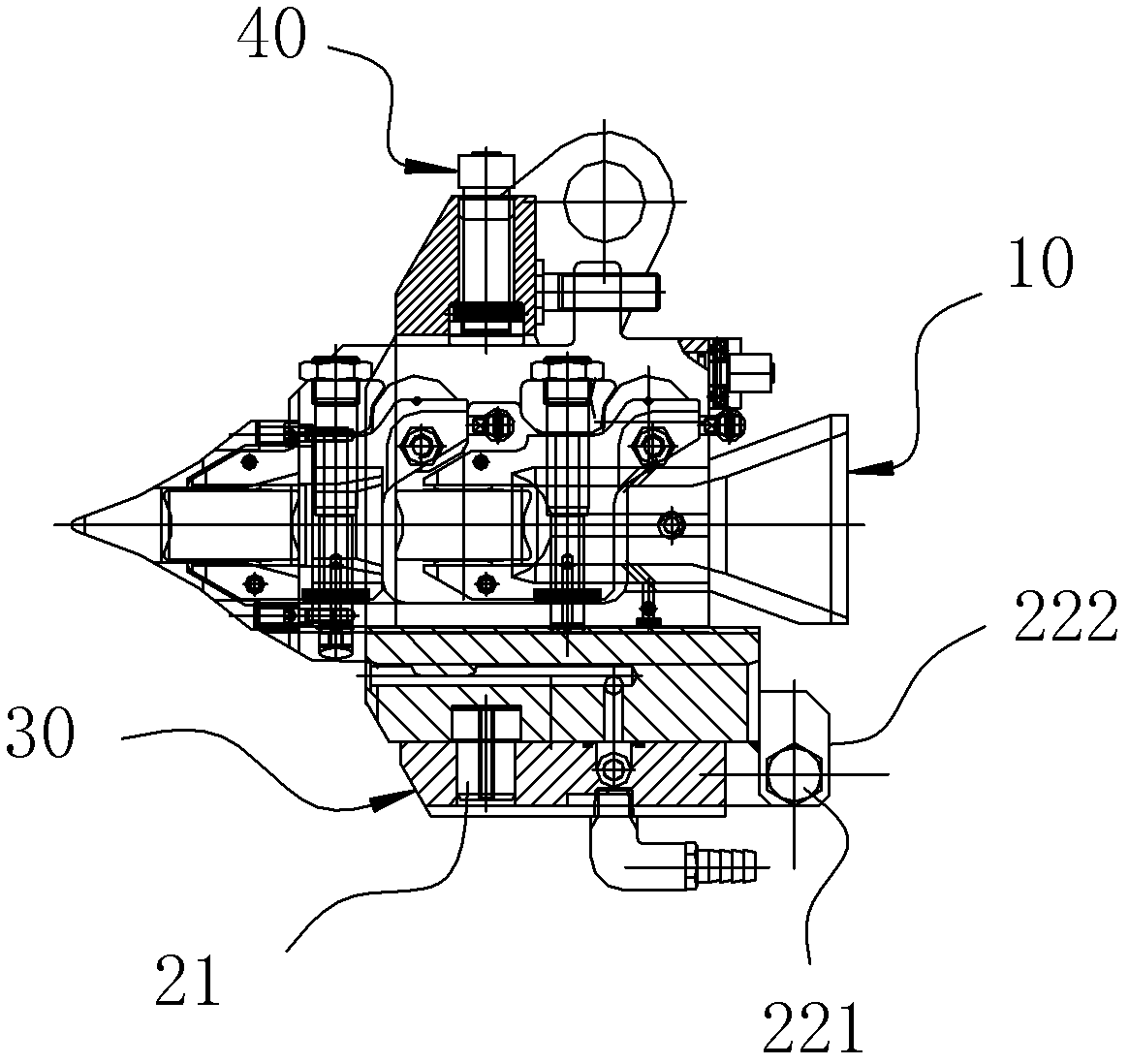

[0009] A centering adjustment device for a guide, comprising a guide body 10 and a base for fixing the guide body 10, the guide body 10 is in conflict with the base, and the centering adjustment device for the guide also includes The adjustment mechanism used to drive the guide body 10 to swing along the mating surface of the base, the swing axis of the adjustment mechanism is located on the passing path of the rolled piece, such as Figure 2-3 shown.

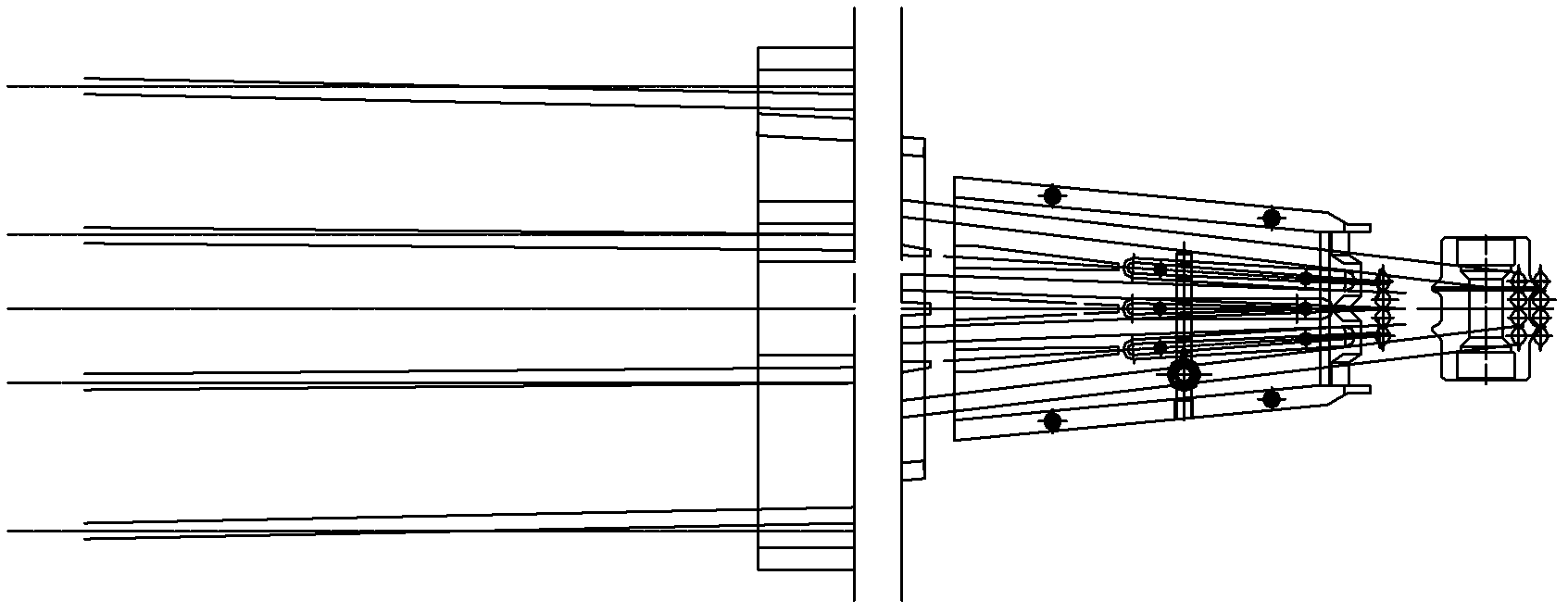

[0010] Such as figure 1 It can be seen from the figure that the actual path of the rolled piece is moving in the split rolling, that is to say, the guide adjustment in its practical application is not suitable for the ordinary translational guide adjustment method with movable beams; due to many Each passing path of a semi-finished rolled piece forms a certain angle with the ideal path, and the deviations of the angles are often different. The lateral movement adjustment of the beam along the frame of the movable beam must not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com