Double-layer flexible circuit board

A flexible circuit board and circuit board technology, which is applied to printed circuit components, electrical connection printed components, etc., can solve the problems of long production time, energy consumption, and high cost, and achieve time saving, process time saving, and drilling reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

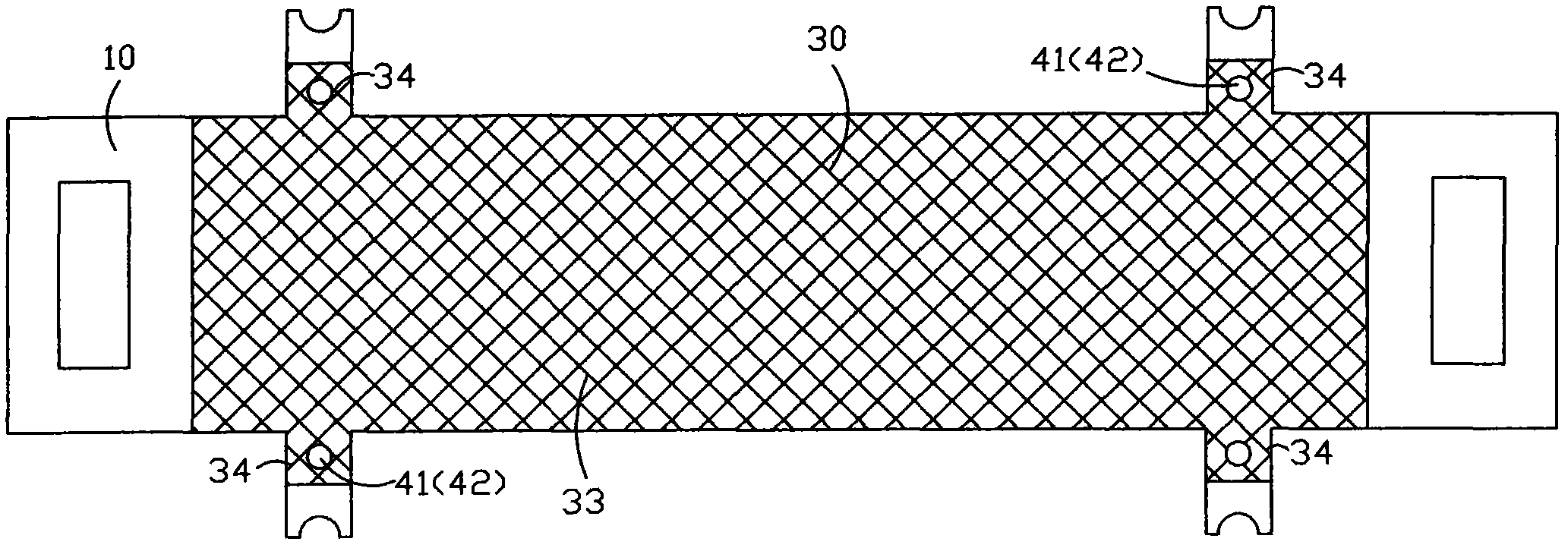

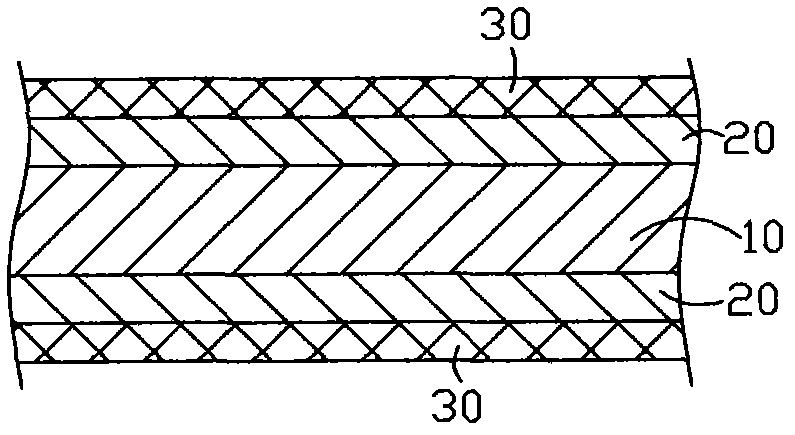

[0019] like Figures 1 to 5 As shown, a double-layer flexible circuit board includes a circuit board base layer 10, a copper foil layer 20 and a shielding layer 30, wherein the circuit board base layer 10 is made of polyimide or polyester film material during specific implementation made.

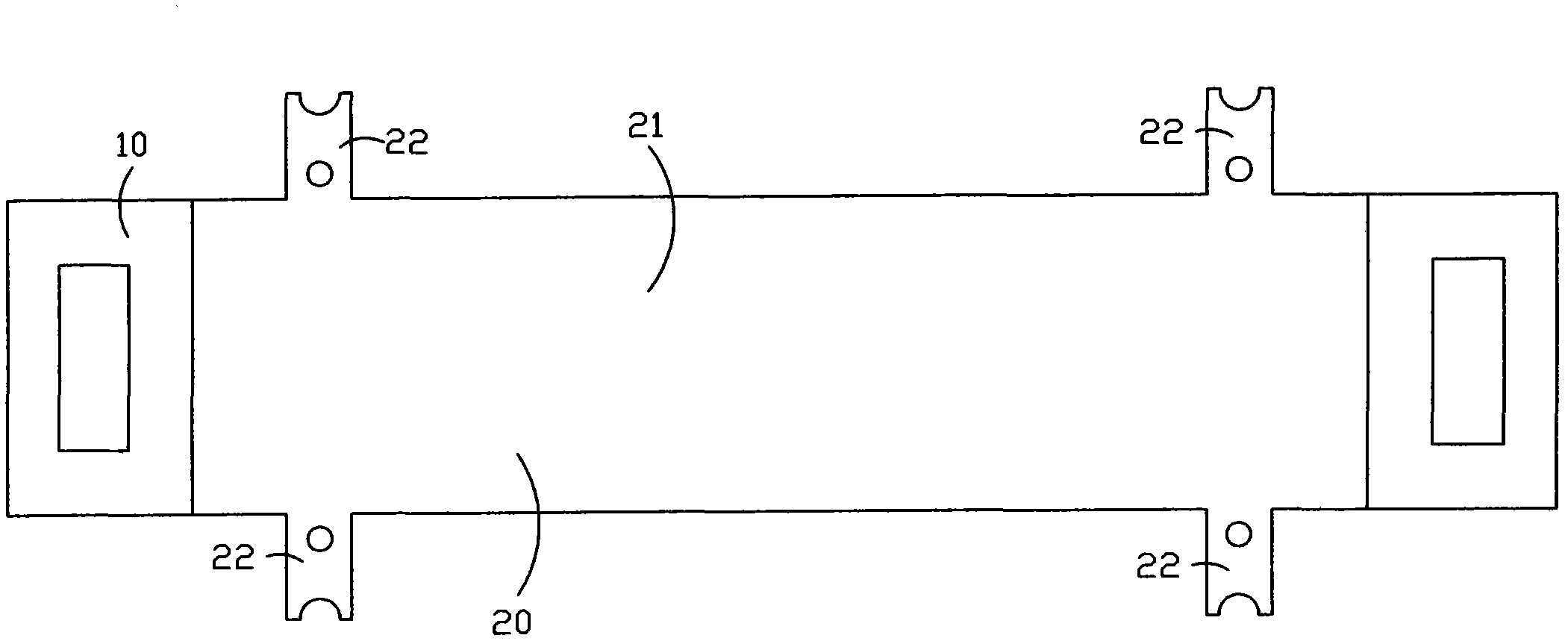

[0020] The circuit board base layer 10 has a top surface and a bottom surface, and the copper foil layer 20 is disposed on the top surface and the bottom surface of the circuit board base layer 10 at the same time.

[0021] In actual implementation, the copper foil layer 20 first needs to be processed by etching and other processes to obtain a specific required circuit, and then the copper foil layer 20 is placed on the top surface and the bottom surface of the circuit board base layer 10 at the same time.

[0022] The copper foil layer 20 includes a circuit part 21 and a circuit board ground metal part 22 , and the circuit part 21 communicates with the circuit board ground metal part 22 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com