A hybrid vehicle internal network architecture

A hybrid vehicle, internal network technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of cumbersome circuits, low reliability, and many wiring harnesses in the vehicle, achieving high efficiency, cost, and improvement. The effect of safety and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

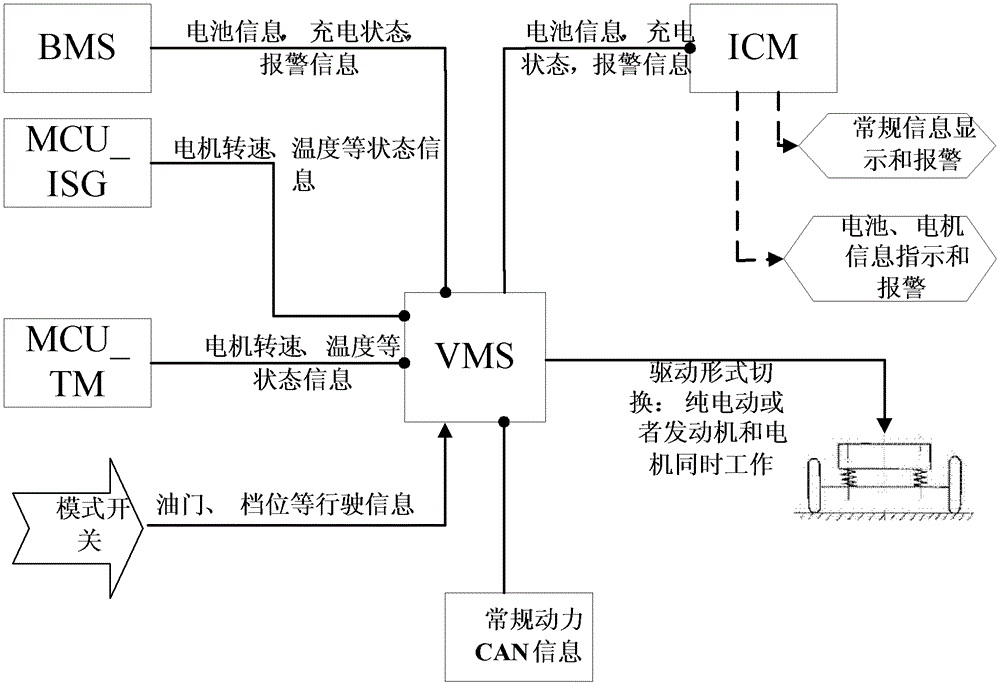

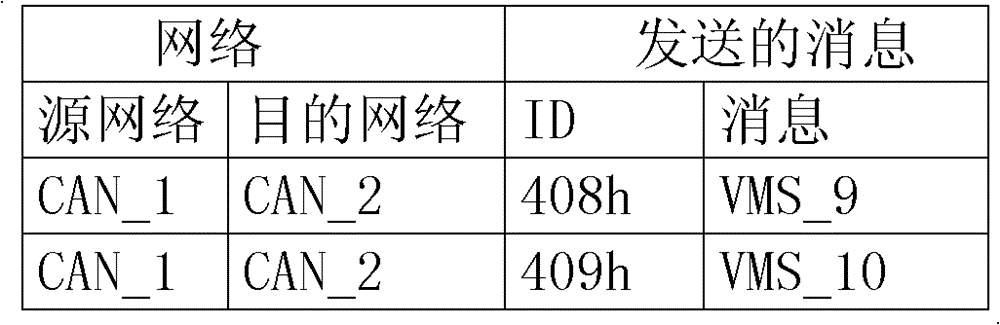

[0023] figure 1 Shown is the hybrid vehicle network system architecture diagram of the embodiment of the present invention, as shown in the figure, the vehicle control network of the present embodiment is composed of two 500KBPS high-speed CAN bus networks, and the nodes on one CAN bus are electrically driven The system forms an electric drive system subnet, also known as the high-speed CAN__1 subnet, and the nodes on the other 500KBPS high-speed CAN bus are traditional power systems to form a traditional power system subnet, called the high-speed CAN__2 subnet. The gateway connecting the traditional power system subnet and the electric drive system subnet is the vehicle controller VMS of the hybrid electric vehicle. The nodes on the traditional power system subnet in this embodiment include: engine control system EMS, brake anti-lock braking system BSM, automatic transmission control system TCU, electric power steering system EPS, air conditioning controller CLM, airbag modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com