Fluorescent powder for white light-emitting diodes (LEDs) and backlight LEDs

A fluorescent powder and backlight technology, applied in the field of fluorescent powder, can solve the problems of low brightness, low color rendering, high color temperature, etc., and achieve the effect of low synthesis temperature, uniform distribution of luminous ions, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

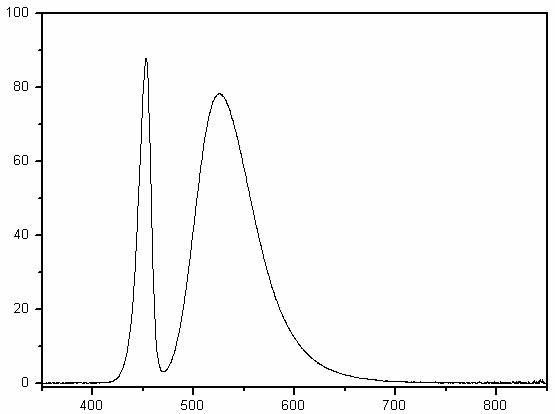

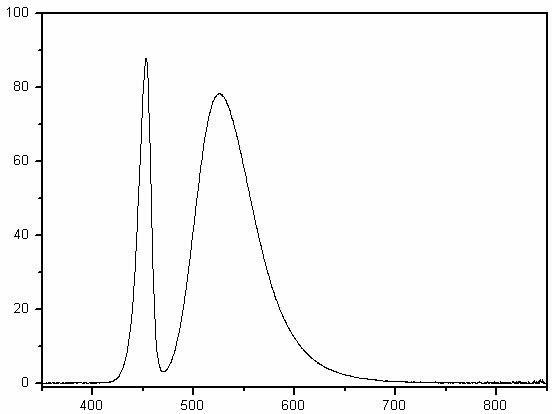

Image

Examples

Embodiment 1

[0015] Example 1 Weigh 0.90 moles of La(NO 3 ) 3 , dissolved in 1000 ml of distilled water, 0.1 mol of Ce(NO 3 ) 3 , 2 moles of Sr(NO 3 ) 2 , 1 mole of Al(NO 3 ) 3 , and stirred for 60 minutes. Add 1.0 mol of oxalic acid, stir for 60 minutes, add 100 ml of ammonia, stir for 30 minutes, add 0.001 mol of BaF 2 Co-solvent, filtered. Constant temperature at 1000°C for 6 hours in a box furnace, broken, put into a crucible, and then constant temperature at 1300°C for 6 hours in a reducing atmosphere, crushed, ball milled, washed, dried at 120°C for 5-10 hours, passed through a 200-mesh drying net , to obtain the phosphor powder.

Embodiment 2

[0016] Example 2 Weigh 0.95 moles of Y (NO 3 ) 3 , dissolved in 1000 ml of distilled water, 0.1 mol of Ce(NO 3 ) 3 , 2 mol Ba(NO 3 ) 2 , 1 mole of Al(NO3)3, stirred for 60 minutes. Add 1.0 mol of oxalic acid, stir for 60 minutes, add 100 ml of ammonia, stir for 30 minutes, add 0.001 mol of SrF 2 Co-solvent, filtered. Keep the temperature at 1000°C for 6 hours in a box furnace, crush it, put it into a crucible, and then keep the temperature at 1300°C for 6 hours in a reducing atmosphere, crush, ball mill, wash, dry at 120°C for 10 hours, and pass through a 200-mesh drying screen to obtain the obtained Phosphor powder.

Embodiment 3

[0017] Example 3 Weigh 0.95 moles of La(NO 3 ) 3 , dissolved in 1000 ml of distilled water, 2 moles of Ca(NO 3 ) 2 , 0.05 mol of Ce(NO 3 ) 2 , 1 mole of Al(NO 3 ) 3 , and stirred for 60 minutes. Add 1.0 mol of oxalic acid, stir for 60 minutes, add 100 ml of ammonia water, stir for 30 minutes, add 0.001 mol of NH 4 Cl co-solvent, filtered. In a box furnace at a constant temperature of 1000 degrees Celsius for 6 hours, broken, put into a crucible, in a reducing atmosphere of 1300 degrees Celsius, kept at a constant temperature for 6 hours, crushed, ball milled, washed, dried at 120 degrees Celsius for 10 hours, passed through a 200-mesh drying net to obtain the described Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com