Low-harm micro-molecular guar gum fracturing fluid

A small molecule, fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large reservoir damage, strong water sensitivity, mismatch between development cost and output economic benefits, etc. To achieve the effect of reducing damage and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

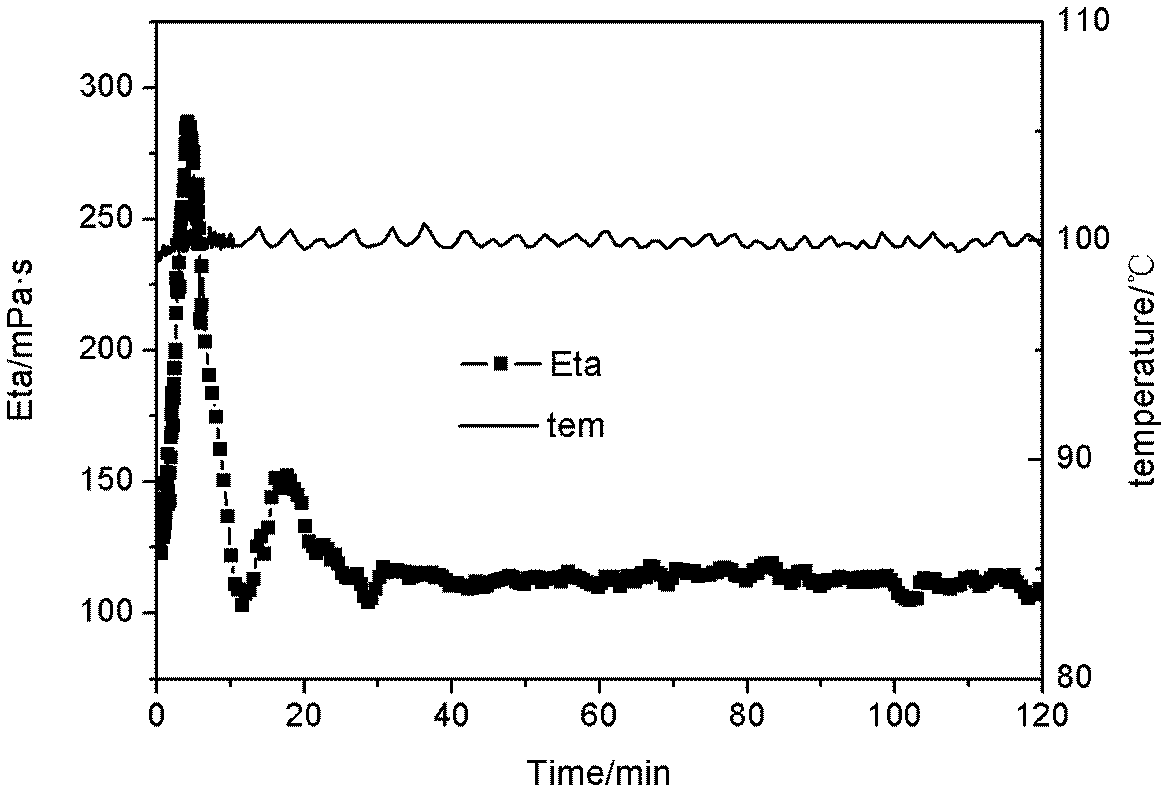

[0021] Add 952.5ml of water into a mixer with a capacity of 2000ml, add 30g of KCl and 1g of formaldehyde under stirring, then weigh 5g of small molecule guar gum, slowly add it into water under stirring, stir at high speed for 5min; then add 0.5g Sodium citrate, 2g sodium carbonate and 10g cetyltrimethylammonium bromide; stir in a mixer for 5min to complete the preparation of the base liquid; take 100ml of the base liquid prepared above, add 0.8g organic Linking agent, continue to stir for 2 minutes, the base liquid and the crosslinking agent react completely to form a jelly that can be hung, and the preparation of the jelly solution is completed; add 0.8g ammonium persulfate to the jelly formed by crosslinking under stirring, ℃ water bath to maintain a constant temperature, after 2h, the jelly is completely broken and hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 50mPa s, and the pH is 14; the rheological properties of the jelly ar...

Embodiment 2

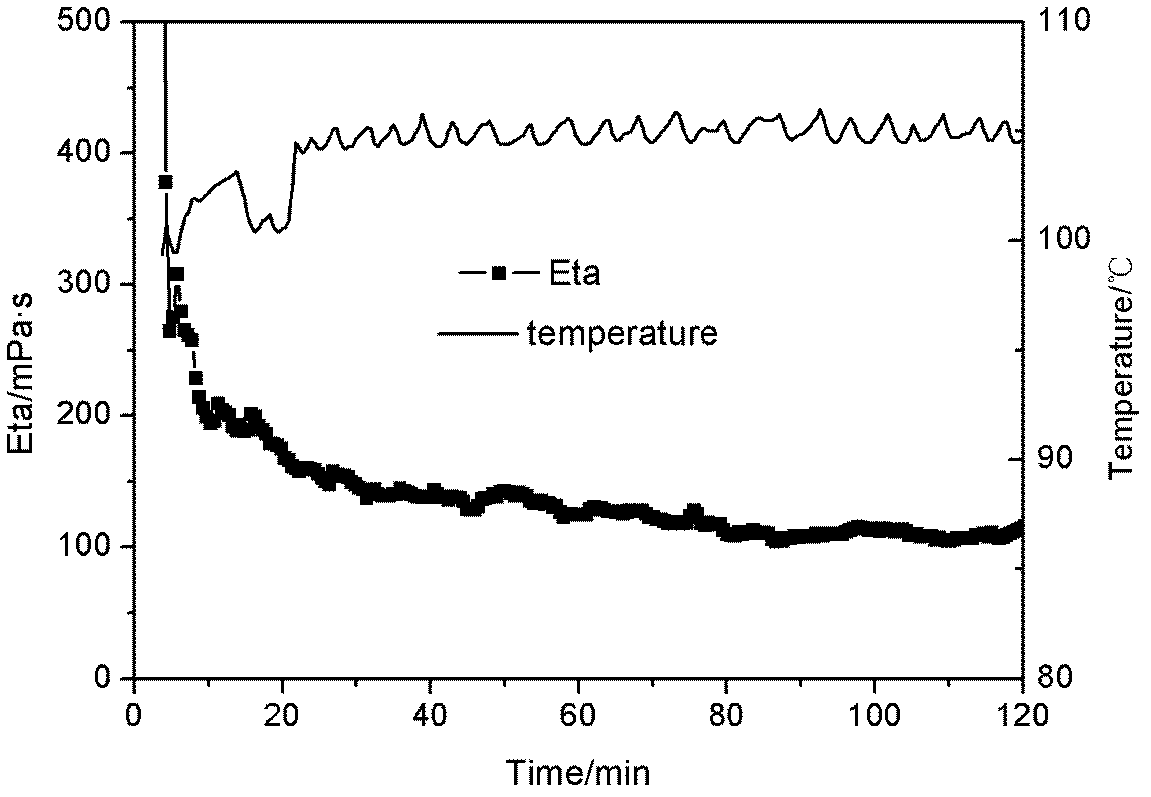

[0023] Add 991.6ml of water into a mixer with a capacity of 2000ml, and add 5g of NH under stirring 4 Cl and 0.1g glutaraldehyde, then weigh 2g of small molecule guar gum, slowly add it into water under stirring, stir at high speed for 5min; then add 0.1g of sodium citrate, 0.2g of sodium hydroxide and 1g of dodecyl Trimethylammonium bromide; stir in a mixer for 5 minutes to complete the preparation of the base liquid; take 100 ml of the base liquid prepared above, add 0.4 g of an organic cross-linking agent under stirring, and continue stirring for 5 min. Add 0.05g of sodium persulfate to the cross-linked jelly under stirring, and keep the temperature in a water bath at 60°C. After 3 hours, the jelly is completely hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 24mPa·s, and the pH is 12; the rheological properties of the jelly are tested with an RS600 rheometer. For the data, see figure 2 ;The viscosity of the gel-breaking solution ...

Embodiment 3

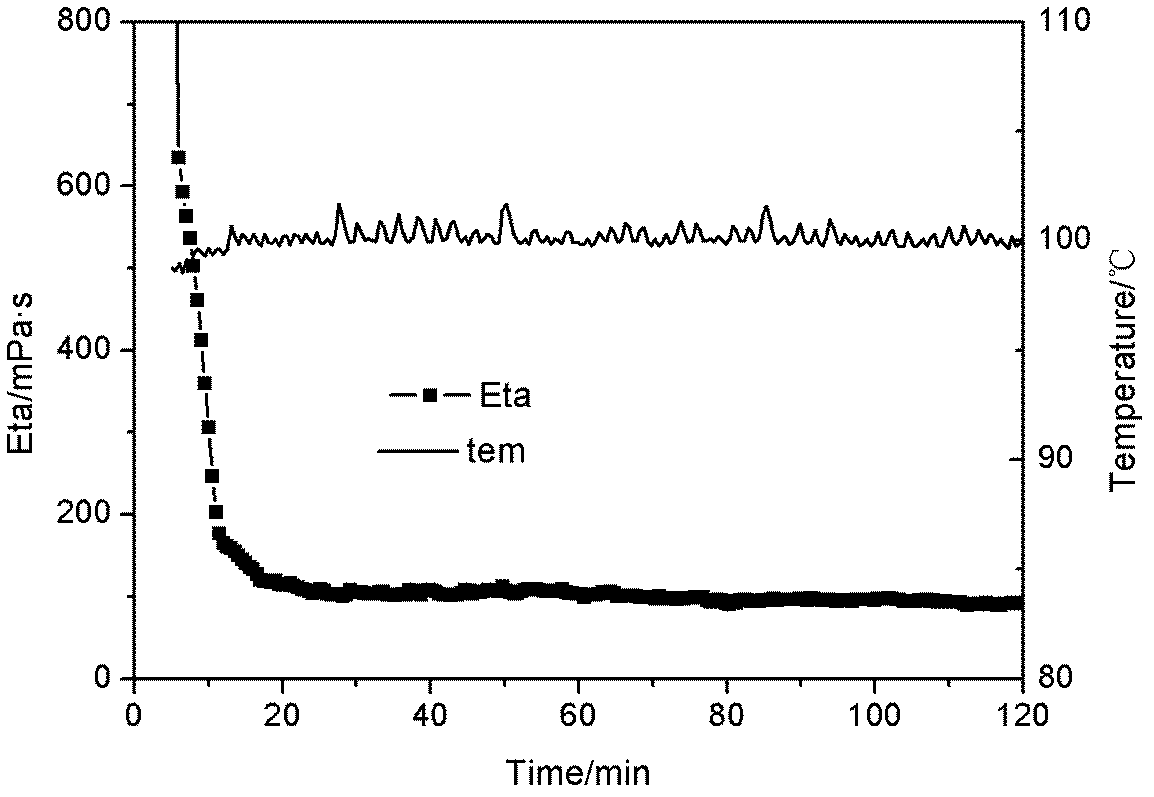

[0025] Add 967.6ml of water into a mixer with a capacity of 2000ml, add 20g of KCl and 0.5g of glutaraldehyde under stirring, then weigh 4g of small molecule guar gum, slowly add it into water under stirring, and stir at high speed for 5 minutes; then Add 0.4g of sodium citrate, 1.5g of ammonia water and 6g of dodecyltrimethylammonium bromide; stir in a mixer for 5min to complete the preparation of the base liquid; take 100ml of the base liquid prepared above, and add 0.6 g organic cross-linking agent, after stirring for 3 minutes, the base liquid and the cross-linking agent completely react to form a jelly that can be hung; Constant temperature, after 1.5h, the jelly is completely hydrated. The apparent viscosity of the base liquid measured with a FANN-35 viscometer is 43mPa·s, and the pH is 13; the rheological properties of the jelly are tested with an RS600 rheometer. For the data, see image 3 ; The viscosity of the gel-breaking fluid measured by a capillary viscometer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com