High-temperature nano-grade anti-carburizing material and coating, and application thereof

An anti-carburization and carbon coating technology, applied in the field of high-temperature resistant materials, can solve the problems of non-wetting, carburization, and air gap generation, and achieve the effects of low cost, high thermal conductivity, and elimination of air gap thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Formula of high-temperature nanometer anti-carburization material (slurry)

[0068] High temperature nanometer anti-carburizing material (slurry) formulations 1 and 2 are shown in Table 1 and Table 2, respectively.

[0069] Table 1 High temperature nanometer anti-carburization material (slurry) formula 1

[0070] raw material name Specifications (mm) content(%) Actual weighed weight (g) Remark Aluminum oxide 0.005 9.86 49.3 Chromium oxide 0.021 12.33 61.65 D01 Powder nanoscale 27.85 139.25 Titanium dioxide nanoscale 0.74 3.7 Silica powder nanoscale 12.33 61.65 liquid water glass industrial grade 20 129.6 sodium tripolyphosphate industrial grade 0.75 3.7 Alcohol Ester-12 industrial grade 13.32 66.6 Propylene Glycol industrial grade 3.82 19.1 Total 100 500

[0071] Note: "D01 powder" in the table refers to one of the se...

Embodiment 2

[0080] Embodiment 2: Nano-scale anti-carburization paint manufacturing process steps

[0081] The production process steps of nanometer anti-carburization coating are as follows:

[0082] According to the dosage of 500g, according to the actual weighing of proportioning 1 to proportioning 7 in the formula table of the above-mentioned embodiment 1, the powder part in various raw materials is weighed;

[0083] Add it to the test-type fine mill, then add zirconia balls with a diameter of 20mm, and discharge after 8 hours of electrified ball milling. The specification of the mixed powder is ≥600 mesh;

[0084] Weigh the mixed powder and liquid water glass, sodium tripolyphosphate, alcohol ester-12 and propylene glycol in proportion, put them into the mixing tank respectively, and use an adjustable stirrer to stir and mix for 30 minutes to form nano-scale anti-carburization Paint, then put into a storage container and ready to use.

Embodiment 3

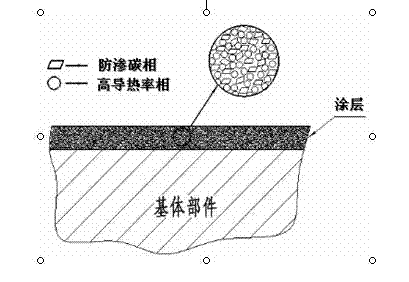

[0085] Embodiment 3: the making of nanometer anti-carburization coating

[0086] 1. Single-coat production

[0087] Coating production: according to the formula table proportioning 1 of the above-mentioned embodiment 1 and the coating production process of the embodiment 2, 500g of the coating is produced;

[0088] Brushing process: Steel pipe blanking—sand blasting—painting with a thickness of 0.1mm—drying at 110°C for 2 hours. The sample is Nano 1#.

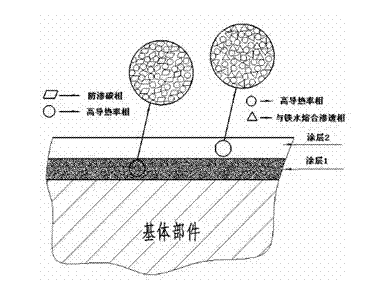

[0089] 2. Double coating production

[0090] Coating production: according to the above-mentioned embodiment 1 formula table proportioning 1, proportioning 2 and embodiment 2 coating production process respectively, make each 500g of coating;

[0091] Brushing process: Steel pipe blanking—sandblasting—brushing ratio 1 paint—3~5h natural drying—brushing ratio 2 paint—drying at 110℃×2h, and the sample is nanometer 2#.

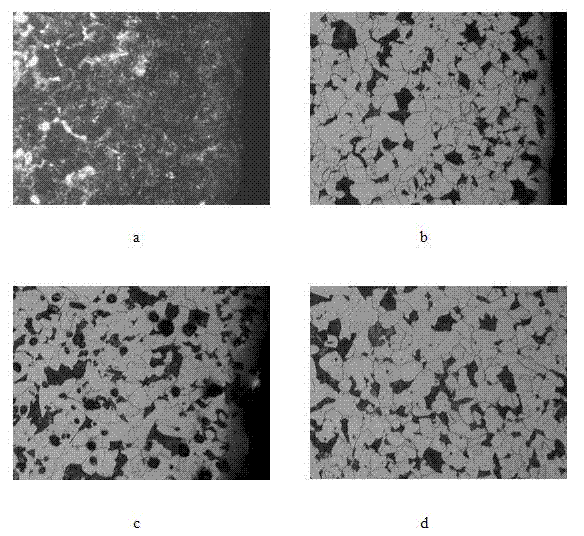

[0092] 3. Anti-carburization experiment

[0093] Install carburizing box—heat carburizing in electric furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com