Natural chlorophyll iron calcium salt and preparation method thereof

A technology of chlorophyll and iron-calcium, which is applied in the field of preparation of natural pigment salts, achieves the effects of wide application, high yield and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

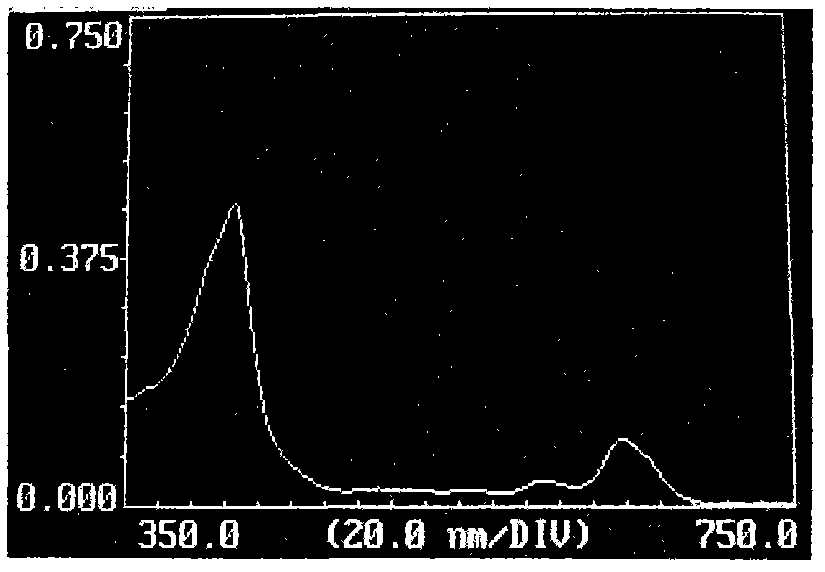

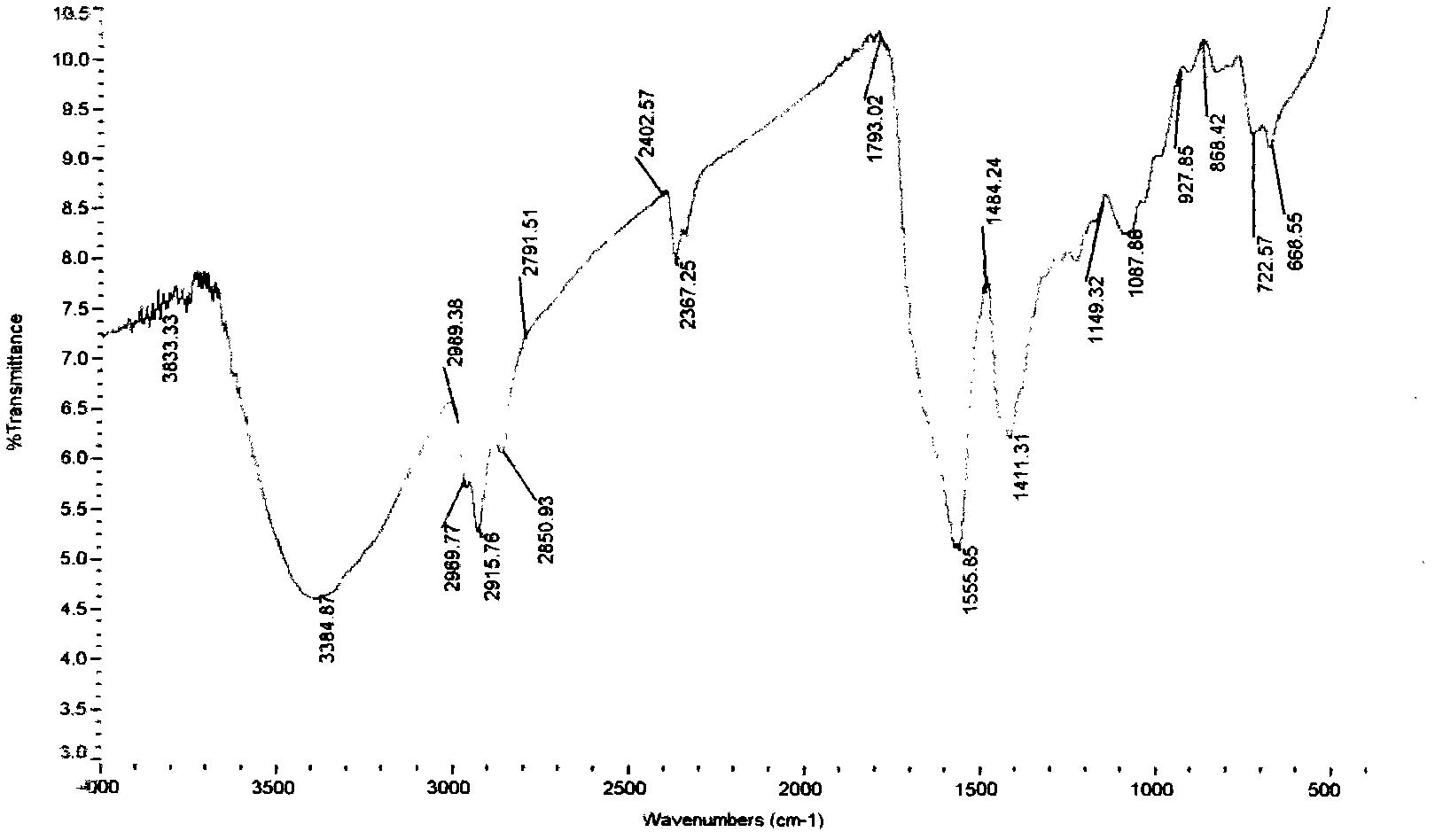

[0026] Chlorophyll iron sodium salt is dissolved in water with a solution concentration of 13g / L and a pH value of 8.2. Calcium acetate is dissolved in water and its solution pH is 5.8 (the solution is ready-to-use). The Ca salt solution was slowly added to the ferric chlorophyllin sodium salt solution. At the same time, magnetically stir at a speed of 1000r / min to make it fully react at room temperature. The aging temperature is 60°C, and the aging time is 15 minutes. Separation by filtration and drying at 80°C to obtain black (dark brown) chlorophyllin iron calcium salt. Carry out the measurement of each index. Wherein, by AVATAR360 type Fourier transform infrared spectrometer and UV7652 spectrophotometer analysis, obtain iron chlorophyllin sodium salt and chlorophyllin iron calcium salt spectrogram (see attached Figure 1~4 ), and analyzed and compared, it was determined that the product was iron chlorophyll calcium salt.

[0027] The calculated yield is 88%

[0028] ...

Embodiment 2

[0037] Sodium iron chlorophyllin is dissolved in water and its solution pH is 9.0. Calcium acetate is dissolved in water and the pH of the solution is 6.8 (the solution is ready-to-use). The Ca salt solution was slowly added to the ferric chlorophyllin sodium salt. At the same time, magnetically stir at a speed of 1000r / min to make it fully react at room temperature. The aging temperature is 70°C, and the aging time is 20 minutes. Separation by filtration and drying at 60°C to obtain black (dark brown) chlorophyllin iron calcium salt.

[0038] The calculated yield is 90%

Embodiment 3

[0040] Sodium ferric chlorophyll is dissolved in water and its solution pH is 8.5. Calcium acetate is dissolved in water and the pH of the solution is 6.5 (the solution is ready-to-use). The Ca salt solution was slowly added to the ferric chlorophyllin sodium salt. At the same time, magnetically stir at a speed of 1000r / min to make it fully react at room temperature. The aging temperature is 80°C, and the aging time is 15 minutes. Separation by filtration and drying at 50°C to obtain black (dark brown) chlorophyllin iron calcium salt.

[0041] The calculated yield was 94%

[0042] Iron chlorophyllin calcium salt traits: small black particles with metallic luster. Insoluble in water and dilute hydrochloric acid, slightly soluble in acetone and ethanol, the solution is yellow-green, soluble in 1:1 hydrochloric acid, easily soluble in alkaline solutions with pH above 12 to obtain a yellow-green solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com