Soil conditioning type controlled release fertilizer special for fruit vegetable in facility, and preparation and application thereof

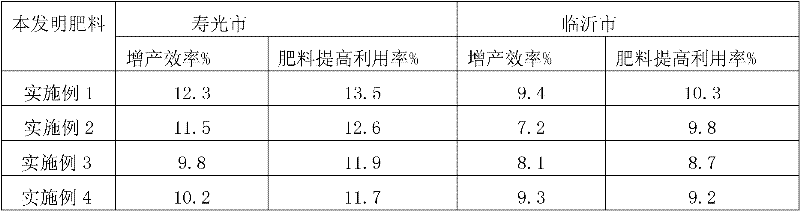

A soil conditioning and controlled-release fertilizer technology, which is applied in the production and application of controlled-release fertilizers, the special controlled-release fertilizers for soil conditioning-type facility fruits and vegetables, and the fields of preparation and application thereof, which can solve the problem that the soil has no conditioning effect and the nutrient controlled-release period is not long. Adaptation, soil differences and other issues, to achieve the effect of improving fertilizer utilization efficiency and increasing vegetable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the special controlled-release fertilizer for conditioning type facility fruits and vegetables of the present invention, the steps are as follows:

[0039] (1) Mix 30-40 parts of peat soil, 20-40 parts of attapulgite soil, and 30-40 parts of biogas residue, and granulate according to the prior art to obtain a soil conditioning composition. The particle size is 2 to 4 mm.

[0040] (2) Soil conditioning composition, sulfur plus high molecular polymer coated urea, 5% humic acid coated urea, 6% recycled thermoplastic resin coated urea, 4% modified epoxy resin coated potassium nitrate of urea primer , urea base coat 4% modified epoxy resin coated diammonium phosphate, 5% humic acid coated diammonium phosphate, 5% humic acid coated potassium nitrate, and potassium sulfate compound fertilizer were put into the mixer and stirred for 5 ~ 8 minutes, mix well and serve. Then the mixed fertilizer is measured and packaged.

[0041] The application of the...

specific Embodiment approach

[0049] The present invention will be further described below in conjunction with the examples, but not limited thereto.

[0050] The amounts and parts of raw materials in the examples are parts by mass, and all percentages are percentages by mass.

[0051] The raw materials in the examples are all commercially available, and can also be prepared according to the prior art, such as CN1246265C (200410024050.X), CN100556866C (200810139610.4) and CN 1246264C (200410024049.7), CN 1257136C (200410035783.3).

[0052] Peat soil: Jilin Hairui Peat Soil Development Company, organic matter content greater than 70%.

[0053] Biogas residue: Biogas residue from the biogas power plant of Mengniu Dairy Group, the main raw material is cow dung.

[0054] Attapulgite: produced by Anhui Mingmei Mineral Co., Ltd., fineness: passed through a 80-mesh sieve.

Embodiment 1

[0055] Embodiment 1: Special controlled-release fertilizer for conditioning type facility fruits and vegetables, the raw material components are as follows:

[0056] Soil conditioning composition 40kg,

[0057] Sulfur plus polymer coated urea 12kg,

[0058] 5% humic acid coated urea 10kg,

[0059] 6% recycled thermoplastic resin coated urea 6kg,

[0060] urea base coat 4% modified epoxy resin coated potassium nitrate 9kg,

[0061] Urea base coat 4% modified epoxy resin coating DAP 5kg,

[0062] 5% humic acid coated diammonium phosphate 3kg,

[0063] 5% humic acid coated potassium nitrate 5kg,

[0064] Potassium sulfate compound fertilizer 10kg.

[0065] Preparation:

[0066] (1) Take 40 kg of peat soil, 20 kg of attapulgite soil, and 40 kg of biogas residue, mix them evenly, and granulate according to the prior art, with a particle size of 2 to 4 mm to obtain a soil conditioning composition.

[0067] (2) The above-mentioned soil conditioning composition, sulfur plus hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com