Surface mortar for outer wall external insulation system using sprayed rigid foam polyurethane

A technology of external wall insulation and rigid polyurethane foam, applied in the field of building materials, can solve the problems of single function, easy cracking, high process cost, etc., and achieve the effect of good filling, not easy to crack, and excellent filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

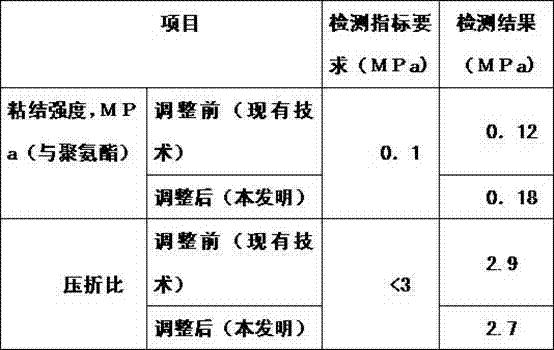

Examples

Embodiment

[0049] Example 1: Spraying the plastering mortar for the external thermal insulation system of rigid polyurethane foam exterior walls, which is made by mixing the following materials in proportion (mass):

[0050] Cement 40%

[0051] Vitrified Beads 30%

[0052] Anti-crack agent 0.15%

[0053] Redispersible rubber powder 0. 5%

[0054] Water retaining agent 0.25%

[0055] Slow drying agent 0.3%

[0056] The balance is filler.

Embodiment 2

[0057] Embodiment 2: Spraying the plastering mortar for the external thermal insulation system of the rigid foam polyurethane exterior wall is mixed in proportion (mass) by the following materials:

[0058] Cement 55%

[0059] Polystyrene particles 30%

[0060] Wood fiber 0.15%

[0061] Redispersible rubber powder 0.8%

[0062] Hydroxypropyl cellulose 0.2%

[0063] Sodium dodecylbenzenesulfonate 0.3%

[0064] The balance is quartz sand.

Embodiment 3

[0065] Embodiment 3: Spraying the plastering mortar for the external thermal insulation system of the rigid foam polyurethane exterior wall, it is formed by mixing the following materials in proportion (mass):

[0066] Cement 58%

[0067] Vitrified microbeads 25%

[0068] Wood fiber 0.15%

[0069] Redispersible rubber powder 0.4%

[0071] Sodium dodecylbenzenesulfonate 0.3%

[0072] Quartz sand 15.85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com