Method for preparing membrane on glass substrate and glass substrate and membrane system structure

A technology of glass substrate and laminated structure, which is applied in the direction of glass/slag layered products, chemical instruments and methods, layered products, etc., which can solve the problems of weak wear resistance and scratch resistance of the protective screen, and failure to meet product quality requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

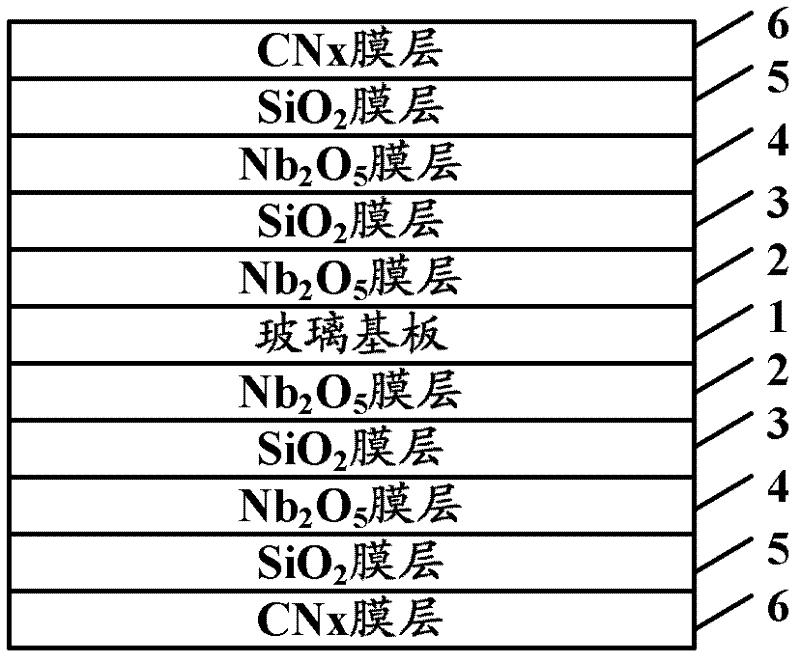

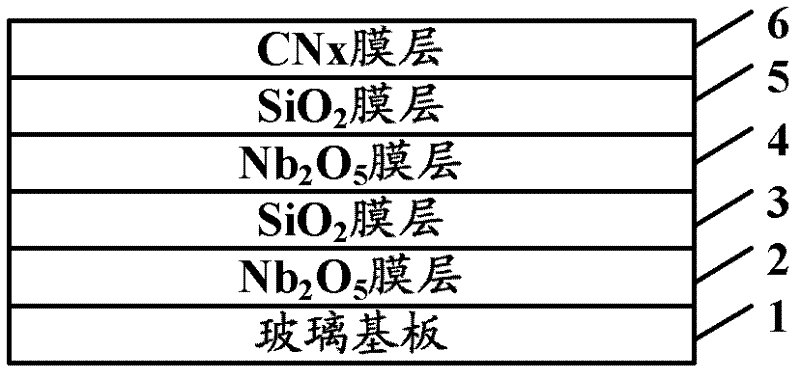

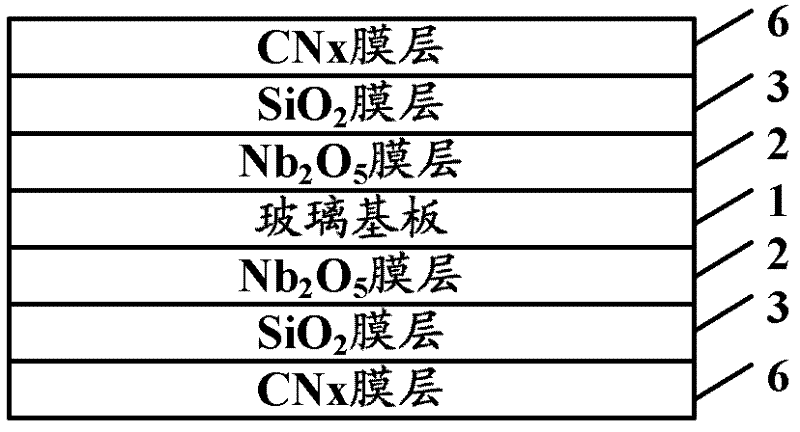

[0018] refer to figure 1 The glass substrate coated with the film layer in the embodiment of the present invention includes a glass substrate 1, an AR mixed film layer formed on both sides of the glass substrate 1 by magnetron sputtering, and an AR mixed film layer formed on both sides of the glass substrate 1 by magnetron sputtering. On the other side, a carbon nitride film layer is generated, wherein the AR mixed film layer is a laminated structure of a low refractive index film layer and a high refractive index film layer, specifically, the low refractive index film layer is silicon dioxide (SiO 2 ) film layer, the high refractive index film layer is niobium pentoxide (Nb 2 o 5 ) film layer, the carbon nitride compound film layer is a CNx film layer, and the first Nb is sequentially arranged on the glass substrate 1 2 o 5 Film layer 2, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com