Semiconductor nanocrystalline composite chalcogenide glass ceramic material and preparation method thereof

A technology of nanocrystalline composite and chalcogenide glass, which is applied in the field of chalcogenide glass-ceramic materials, can solve the problems of performance and preparation of composite materials, and achieve the effect of improving thermodynamic stability and environmental impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

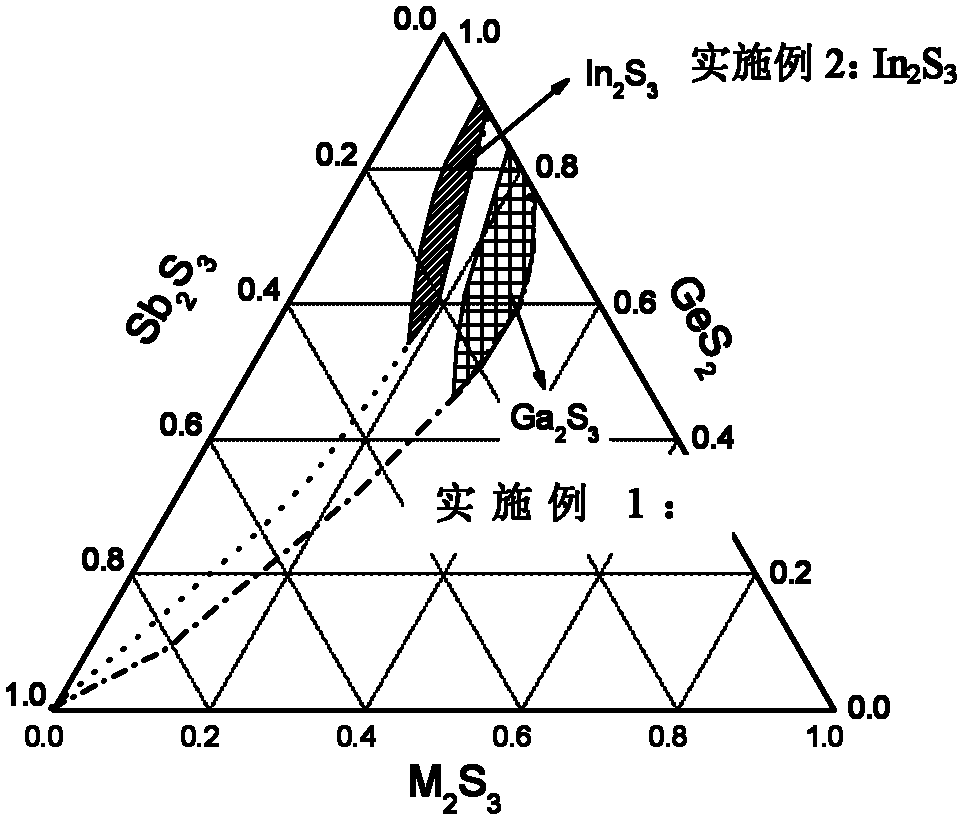

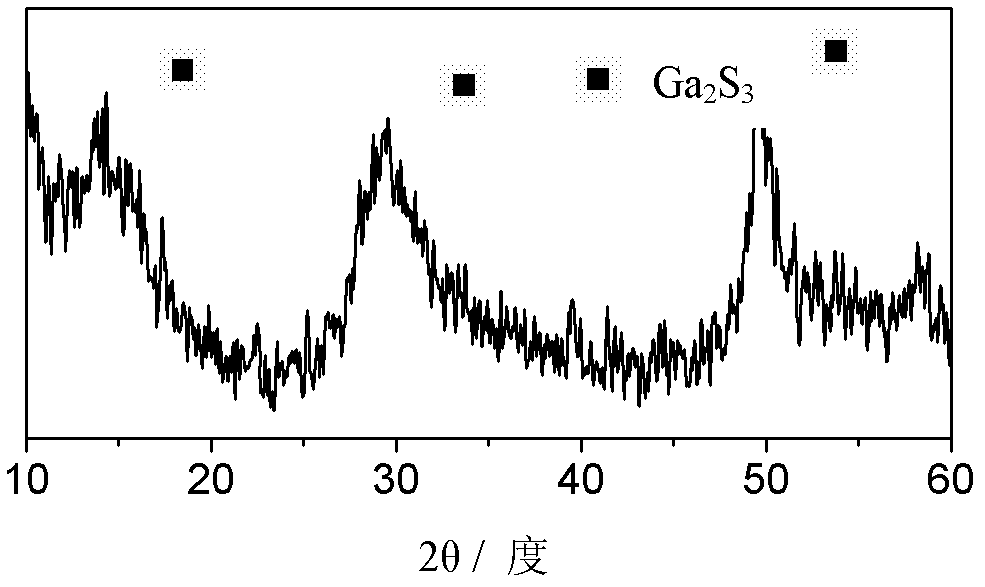

[0028] An infrared transparent Ga 2 S 3 Nanocrystalline composite chalcogenide glass-ceramic material, its molar composition is expressed as: 0.62GeS 2 0.13Sb 2 S 3 0.25Ga 2 S 3 , at figure 1 Ga shown 2 S 3 The glass composition range in which the crystals are precipitated.

[0029] The specific preparation method is as follows:

[0030] (1) Composition selection: such as figure 1 As shown, according to the crystal phase precipitated as needed (Ga 2 S 3 or In 2 S 3 ), determine the corresponding quasi-binary or quasi-ternary glass system such as GeS 2 -Ga 2 S 3 、GeS 2 -Sb 2 S 3 -Ga 2 S 3 or GeS 2 -In 2 S 3 、GeS 2 -Sb 2 S 3 -In 2 S 3 The range of glass formation, and then select the glass composition that is rich in the composition of the crystal phase to be precipitated at the edge of the formation range, so as to determine the molar composition chemical formula (1-x-y)GeS 2 · xSb 2 S 3 ·yM 2 S 3 Medium x and y values, rich in the crystal phas...

Embodiment 2

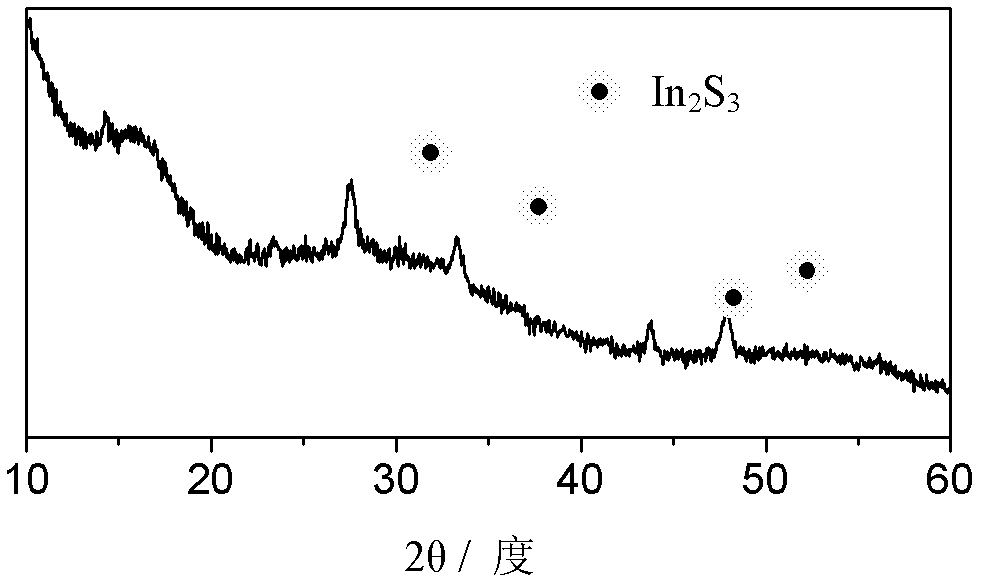

[0038] An infrared-transmitting In 2 S 3 Nanocrystalline composite chalcogenide glass ceramics, its molar composition is expressed as: 0.65GeS 2 0.20Sb 2 S 3 0.15In 2 S 3 , at figure 2 Shown In 2 S 3 The glass composition range in which the crystals are precipitated.

[0039] The specific preparation method is as follows:

[0040] (1) Composition selection: such as figure 1 As shown, according to the crystal phase precipitated as needed (Ga 2 S 3 or In 2 S 3 ), determine the corresponding quasi-binary or quasi-ternary glass system such as GeS 2 -Ga 2 S 3 、GeS 2 -Sb 2 S 3 -Ga 2 S 3 or GeS 2 -In 2 S 3 、GeS 2 -Sb 2 S 3 -In 2 S 3 The range of glass formation, and then select the glass composition that is rich in the composition of the crystal phase to be precipitated at the edge of the formation range, so as to determine the molar composition chemical formula (1-x-y)GeS 2 · xSb 2 S 3 ·yM 2 S 3 Medium x and y values, rich in the crystal phase comp...

Embodiment 3-4

[0048] In the following examples, the preparation methods of glass and glass ceramics are the same as in Example 1, and the different glass compositions and performance test results used are listed in Table 1 and Table 2, respectively.

[0049] The glass composition of table 1 embodiment 3-4

[0050] serial number

GeS 2

Sb 2 S 3

Ga 2 S 3

Example 3

0.70

0.10

0.20

Example 4

0.79

0.05

0.16

[0051] The performance test result of the base glass and glass-ceramic of table 2 embodiment 3-4

[0052]

[0053] Note: The second harmonic signal strength in the table is the ratio of Y-cut quartz crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com