Polypyrrole/titanium dioxide composite adsorbent, its preparation, application and regeneration methods

A technology of titanium dioxide and composite adsorption, which is applied in the direction of chemical instruments and methods, separation methods, filter regeneration, etc., to achieve the effects of easy regeneration, easy availability of raw materials, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

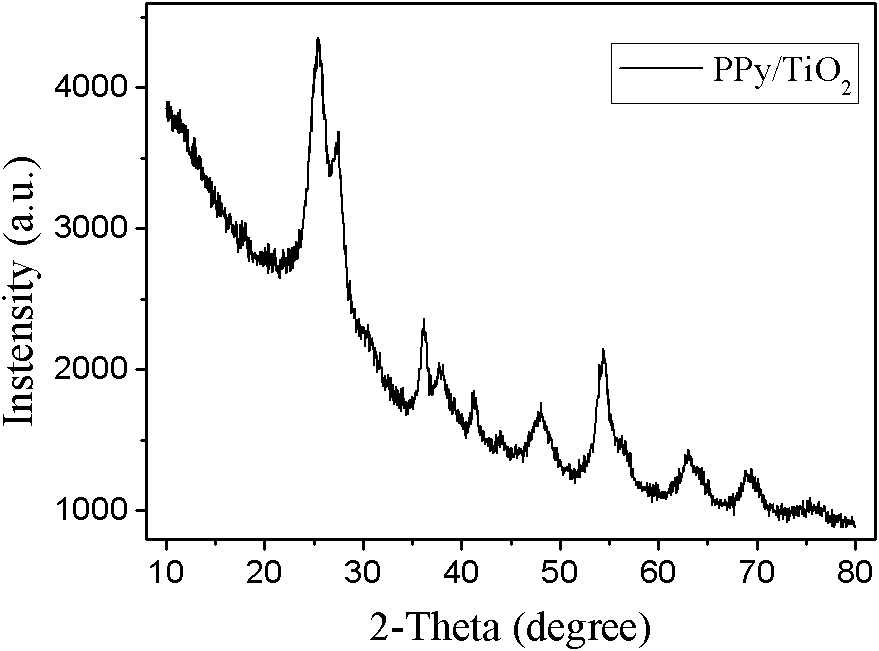

specific Embodiment 1

[0039] preparation:

[0040](1) Take 20 mL of butyl titanate and 20 mL of n-propanol to prepare the alcohol solution of butyl titanate; under vigorous stirring, slowly add the alcohol solution of butyl titanate until the pH is 1 and the temperature is Hydrolyze in 400 mL of nitric acid solution at 100°C and stir for 5 hours to obtain a transparent titanium dioxide sol.

[0041] (2) Add 0.10 mL of pyrrole monomer to the obtained sol at -20~10 °C, mix and stir for 0.5 h, then add 20 mL, 1 mol L -1 The ferric chloride solution was used as an oxidant to realize oxidative polymerization. After the dropwise addition, it was left to stand at this temperature for more than 20 h. After filtering and drying, a black product was obtained, which was the polypyrrole composite nano-titanium dioxide adsorption material.

[0042] application:

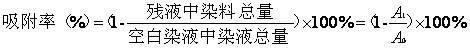

[0043] (3) The prepared adsorbent was used to remove the anionic dye acid red G in the solution. Add an initial concentration of 500 mg L to a dark...

specific Embodiment 2

[0046] preparation:

[0047] (1) Take 10 mL of butyl titanate and 10 mL of isopropanol to prepare an alcohol solution of butyl titanate; under vigorous stirring, slowly add the alcohol solution of butyl titanate until the pH is 2 and the temperature is Hydrolyze in 100 mL of nitric acid solution at 80°C and stir for 5 hours to obtain a transparent titanium dioxide sol.

[0048] (2) Add 5.0 mL of pyrrole monomer to the obtained sol at 10-25 °C, mix and stir for 0.5 h, then add 10 mL, 1 mol L -1 The ferric chloride solution was used as an oxidant to realize oxidative polymerization. After the dropwise addition, it was left to stand at this temperature for more than 20 h. After filtering and drying, a black product was obtained, which was the polypyrrole composite nano-titanium dioxide adsorption material.

[0049] application:

[0050] (3) The prepared adsorbent was used to remove acid red G in the solution. Add an initial concentration of 500 mg L to a darkened brown bottle...

specific Embodiment 3

[0053] preparation:

[0054] (1) Take 10 mL of butyl titanate and 20 mL of absolute ethanol to prepare an alcohol solution of butyl titanate; under vigorous stirring, slowly add the alcohol solution of butyl titanate until the pH is 2 and the temperature is Hydrolyze in 100 mL of nitric acid solution at 25 °C and stir for 5 hours to obtain a transparent titanium dioxide sol.

[0055] (2) Add 30 mL of pyrrole monomer to the obtained sol at 50-75 °C, mix and stir for 0.5 h, then add 150 mL, 1 mol L -1 The ammonium persulfate solution was used as an oxidant to realize oxidative polymerization. After the dropwise addition, the reaction was continued at this temperature for more than 20 h. After filtration and drying, a black product was obtained, which was the polypyrrole composite nano-titanium dioxide adsorption material.

[0056] application:

[0057] (3) The prepared adsorbent is used to remove methylene blue in the solution. Add an initial concentration of 500 mg L to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com