Manufacture method for low-voltage electric power cable used for nuclear power station

A low-voltage electric power and cable manufacturing technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problem that cables cannot meet high insulation and high flame retardancy at the same time, and achieve high friction and high Insulation, high shear force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

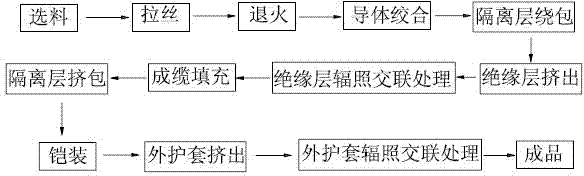

[0026] Manufacturing method of low-voltage power cables for nuclear power plants, including material selection—drawing—annealing—conductor stranding—isolation layer wrapping—insulation layer extrusion—insulation layer irradiation cross-linking treatment—cable filling—isolation layer extrusion—armoring— Outer sheath extrusion - outer sheath irradiation crosslinking treatment - finished product step;

[0027] Insulation layer extrusion: The insulation layer is extruded by double-layer co-extrusion, the inner layer is made of PE screw, extruded with irradiated cross-linked polyethylene, and the processing temperature is 125°C; the outer layer is made of semi-extruded mold with a compression ratio of 1.25:1 The equal-depth and equal-distance screw is insulated from the inner layer while extruding a low-smoke, halogen-free thermosetting polymer to form an insulating layer. The processing temperature is controlled at 110°C, and the cooling water temperature is 25°C;

[0028] Insulat...

Embodiment 2

[0041] Manufacturing method of low-voltage power cables for nuclear power plants, including material selection—wire drawing—annealing—conductor stranding—isolation layer wrapping—insulation layer extrusion—insulation layer irradiation cross-linking treatment—cable filling—isolation layer extrusion—armoring— Outer sheath extrusion - outer sheath irradiation crosslinking treatment - finished product step;

[0042] Insulation layer extrusion: The insulation layer is extruded by double-layer co-extrusion, the inner layer is made of PE screw, extruded with irradiated cross-linked polyethylene, and the processing temperature is 145°C; the outer layer is made of semi-extruded mold with a compression ratio of 1.5:1 The equal-depth and equal-distance screw is insulated from the inner layer while extruding a low-smoke, halogen-free thermosetting polymer to form an insulating layer. The processing temperature is controlled at 130°C, and the cooling water temperature is 30°C;

[0043] Ins...

Embodiment 3

[0056] Manufacturing method of low-voltage power cables for nuclear power plants, including material selection—drawing—annealing—conductor stranding—isolation layer wrapping—insulation layer extrusion—insulation layer irradiation cross-linking treatment—cable filling—isolation layer extrusion—armoring— Outer sheath extrusion - outer sheath irradiation crosslinking treatment - finished product step;

[0057] Insulation layer extrusion: The insulation layer is extruded by double-layer co-extrusion, the inner layer is made of PE screw, extruded with irradiated cross-linked polyethylene, and the processing temperature is 165°C; the outer layer is made of semi-extruded mold with a compression ratio of 1.8:1 The equal-depth and equal-distance screw is insulated from the inner layer while extruding a low-smoke, halogen-free thermosetting polymer to form an insulating layer. The processing temperature is controlled at 150°C, and the cooling water temperature is 35°C;

[0058] Insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com