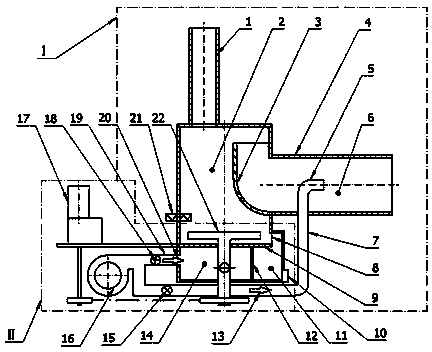

Biomass particle combustion apparatus and combustion method for same

A biomass particle and combustion device technology, which is applied in the combustion method, combustion equipment, solid fuel combustion and other directions, can solve the problems of insufficient combustion of biomass particle fuel, easy slagging and particle ash corrosion of equipment, and high soot content. Achieve the effect of small transformation, flexible layout, and easy slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Cotton stalk pellets are used as fuel. During the operation of the biomass pellet combustion device, the temperature of the hot gas is controlled between 500°C and 650°C. The volume ratio of the primary air to the secondary air is 4:6. Fork, and control the speed of gray fork to 0.85r / min, the output flame temperature is 1010°C after detection.

Embodiment 2

[0044] Using wood pellets as fuel, during the operation of the combustion device, the temperature of the hot gas is controlled between 600°C and 750°C, the volume ratio of the primary air to the secondary air is 7:13, and the ash fork with three levers is used to control The speed of the gray fork is 0.7r / min, and the output flame temperature is 1090°C after detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com