Method for preparing porous magnetic and catalytic double-functional one-dimensional composite material

A composite material and dual-function technology, applied in the direction of spinning solution preparation, fiber treatment, fiber chemical characteristics, etc., to achieve high photocatalytic activity, strong ferromagnetism, and uniform product distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

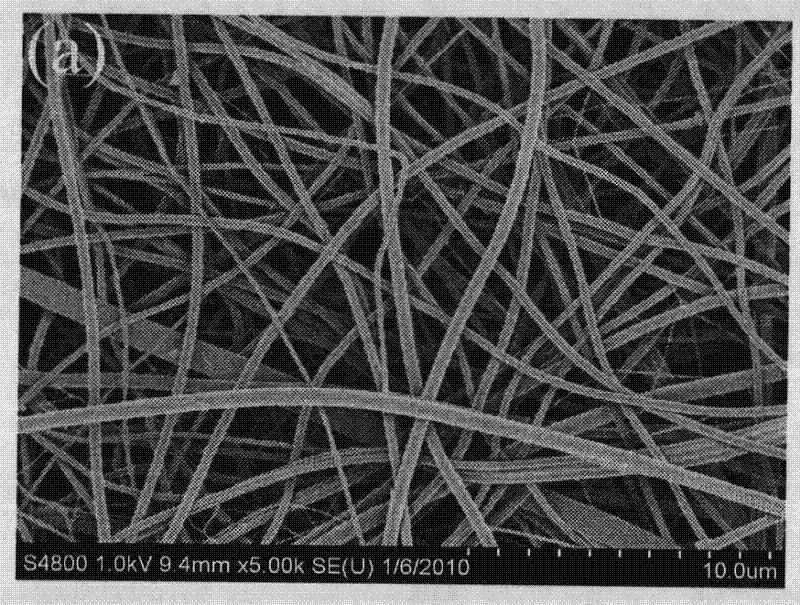

[0044] Example 1: Preparation of one-dimensional metal salt / PVP precursor.

[0045] (1) 1.8mmolZn(Ac) 2 2H 2 O, 1.8mmol Fe(NO 3 ) 3 9H 2 O and 0.1 mmol AgNO 3 Dissolve in 1 g of distilled water and 1 g of absolute ethanol, and stir magnetically for 2 hours at room temperature to fully dissolve to obtain solution a.

[0046] (2) Slowly add 1200mg of polyvinylpyrrolidone (PVP) into 10g of absolute ethanol, and magnetically stir for 2 hours to completely dissolve it to form a transparent solution b,

[0047] (3) Finally, solution b was slowly added to solution a, and magnetic stirring was continued for 2 hours to obtain a yellow viscous solution c.

[0048] (4) Finally, the solution c is spun by an electrospinning device to obtain a one-dimensional fiber. The electrospinning parameters are as follows: the solution flow rate is 0.6-1.2mLh -1 , the distance between the nozzle and the ground plate is 15cm, and the voltage is 20-25kV. The obtained fibers were dried in an oven...

Embodiment 2

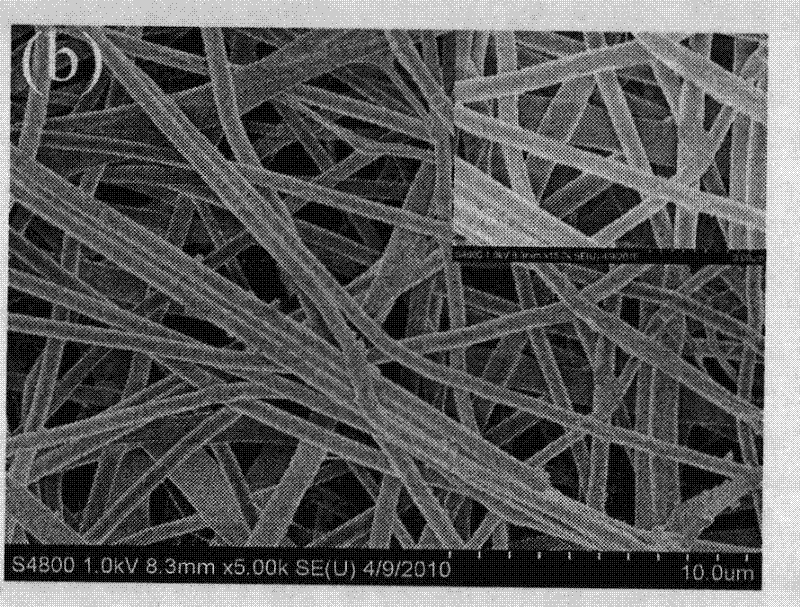

[0050] Embodiment 2: preparation of ZnFe with different Ag loads 2 o 4 / Fe 3 o 4 / Ag mesoporous carbon fibers.

[0051] (1) 1.8mmolZn(Ac) 2 2H 2 O, 1.8mmol Fe(NO 3 ) 3 9H 2 O and 0~0.2mmolAgNO 3 Dissolve in 1g of distilled water and 1g of absolute ethanol, stir magnetically at room temperature for 2 hours to fully dissolve to obtain solution a;

[0052] (2) Slowly add 1200mg of PVP into 10g of absolute ethanol, and magnetically stir for 2 hours to completely dissolve it to form a transparent solution b;

[0053] (3) Finally, solution b is slowly added to solution a, and magnetic stirring is continued for 2 hours to obtain a yellow viscous solution c;

[0054] (4) Finally, the solution c is spun by an electrospinning device to obtain a one-dimensional fiber. The electrospinning parameters are as follows: the solution flow rate is 0.6mLh -1 , the distance between the nozzle and the ground plate is 15cm, and the voltage is 20kV. The obtained fibers were dried in an ov...

Embodiment 3

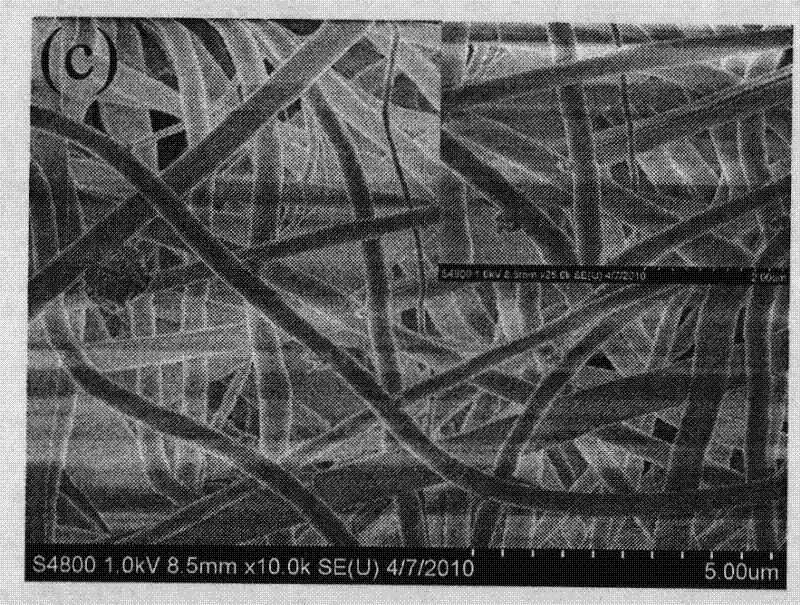

[0060] Embodiment 3: preparation ZnFe 2 o 4 / ZnO / Ag one-dimensional composites.

[0061] (1) 1.8mmolZn(Ac) 2 2H 2 O, 1.8mmol Fe(NO 3 ) 3 9H 2 O and 0.1 mmol AgNO 3 Dissolve in 1g of distilled water and 1g of absolute ethanol, and stir magnetically for 2 hours at room temperature to fully dissolve (1).

[0062] (2) Slowly add 1200mg of PVP into 10g of absolute ethanol, and magnetically stir for 2 hours to completely dissolve it to form a transparent solution (2),

[0063] (3) Finally, the solution (2) was slowly added to the solution (1), and magnetic stirring was continued for 2 hours to obtain a yellow viscous solution (3).

[0064] (4) Finally, the solution (3) is spun by electrospinning equipment to obtain one-dimensional fibers. The electrospinning parameters are as follows: the solution flow rate is 0.6mLh -1 , the distance between the nozzle and the ground plate is 15cm, and the voltage is 20kV. The obtained fibers were dried in an oven at 60 °C for 12 h.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com