Method for preparing single-phase polycrystalline bismuth molybdate by using solid-phase reaction method and application

A solid-state reaction method, bismuth molybdate technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of long time consumption, low yield, unsuitable for large-scale production, etc., and achieve the preparation process Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Bismuth powder (purity 99.999%) and molybdenum trioxide (purity 99.5%) are mixed in a molar ratio of 1:5, and a total of 2 g is mixed in a mortar.

[0024] (2) Place the well-mixed mixture in a 100ml stainless steel ball mill tank, vacuumize it, and fill it with argon protection; the mixture and agate balls are mixed in a mass ratio of 1:20, and 10ml of absolute ethanol (analytical grade, mass Score greater than 99.7%), ball milling with 450 rev / min rotating speed for 40 hours.

[0025] (3) The ball-milled powder is washed with absolute ethanol (analytical grade, mass fraction greater than 99.7%), dried, pressed into tablets (20 MPa), and calcined in a vacuum atmosphere at 700° C. for 10 hours.

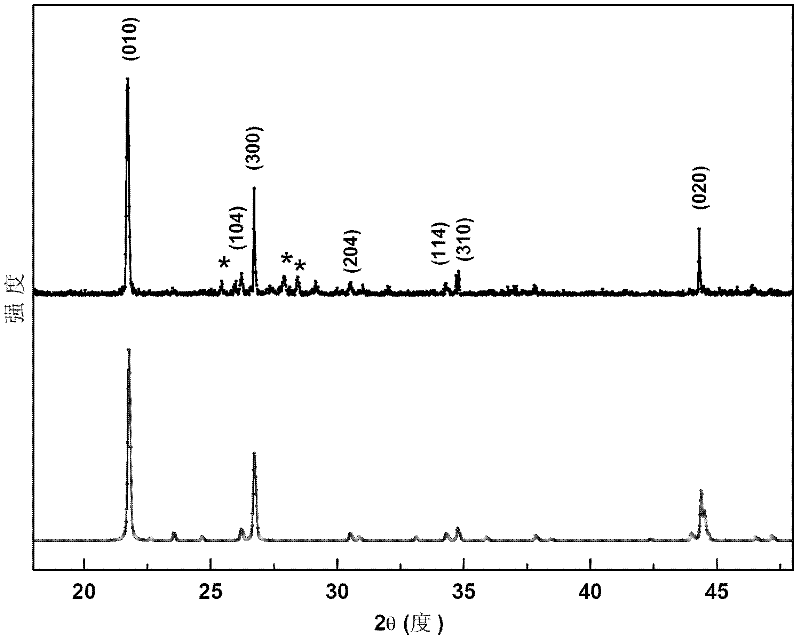

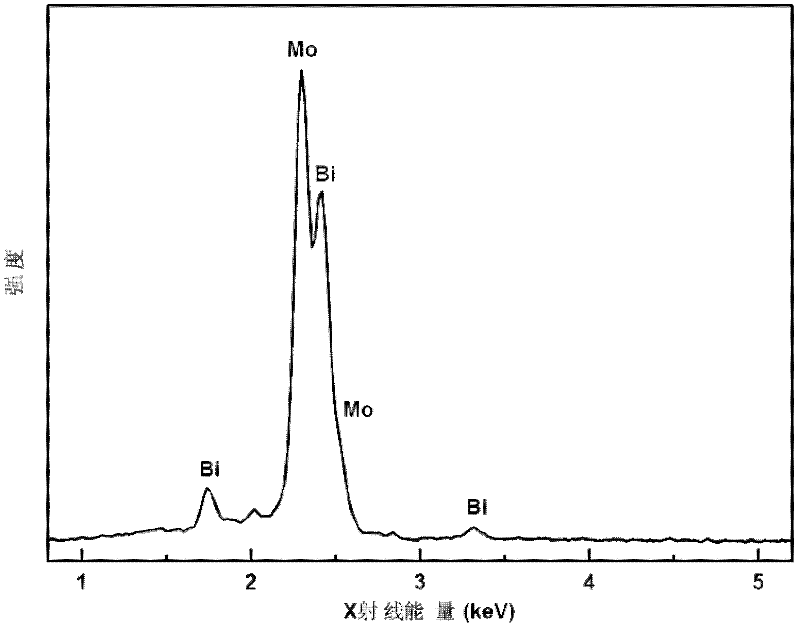

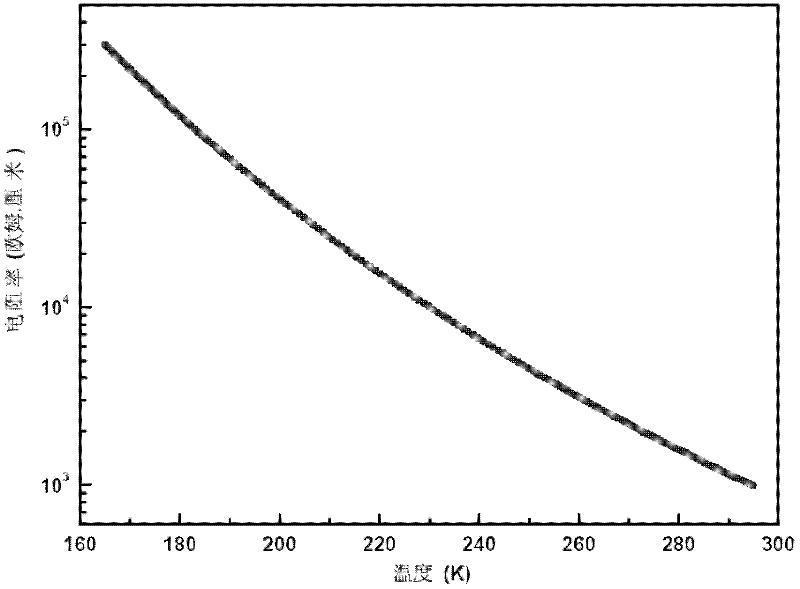

[0026] (4) adopt XRD to carry out phase analysis to final product and find: sample crystallization is good (results such as figure 1 shown); EDS analysis shows that the ratio of Bi and Mo elements is about 0.14:1 (the results are as follows figure 2 shown); comprehensive...

Embodiment 2

[0029] (1) Bismuth powder (purity 99.999%) and molybdenum trioxide (purity 99.5%) are mixed in a molar ratio of 1:5, and a total of 2 g is mixed in a mortar.

[0030] (2) The mixture was pressed into tablets (20 MPa), and calcined in a vacuum atmosphere at 700° C. for 10 hours.

[0031] (3) XRD was used to analyze the phase of the final product, and it was found that the product was impure and had many impurity phases; it indicated that mechanical ball milling was very critical for the solid-phase synthesis of single-phase bismuth molybdate.

Embodiment 3

[0033] (1) Bismuth powder (purity 99.999%) and molybdenum trioxide (purity 99.5%) are mixed in a molar ratio of 1:5, and a total of 2 g is mixed in a mortar.

[0034] (2) Place the well-mixed mixture in a 100ml stainless steel ball mill tank, vacuumize it, and fill it with argon protection; the mixture and agate balls are mixed in a mass ratio of 1:20, and 10ml of absolute ethanol (analytical grade, mass Score greater than 99.7%), ball milling with 450 rev / min rotating speed for 40 hours.

[0035] (3) The ball-milled powder is washed with absolute ethanol (analytical grade, mass fraction greater than 99.7%), dried, pressed into tablets (20 MPa), and calcined in a vacuum atmosphere at 680° C. for 10 hours.

[0036] (4) XRD was used to analyze the phase of the final product, and it was found that the sample crystallized better, but the single-phase property was worse than that of the product calcined at 700°C for 10 hours; it shows that choosing an appropriate calcination temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com