Solid fermentation method of fragrant white spirit

A technology of solid-state fermentation of Luzhou-flavor liquor, applied in the field of wine making, can solve the problems of reducing production, reducing, and consuming ethanol, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment one uses the scheme of prior art method to ferment and produce wine

[0019] The number of retorts in the selected cellar is 10 retorts, and the capacity of each retort is 2.0m 3 .

[0020] Ingredients to moisten the grain and mix grains: take 200kg of sorghum and mix evenly, then add water to moisten the grain. The temperature of the moistening water is between 90°C and boiling temperature, and the amount of moistening water is 150kg. The sorghum crushing degree is 6-8 cloves / grain. 50 minutes before the retort, use a rake to dig out a retort of Luzhou-flavored cellar-exiting wine grains from the dross dam, pour the moistened sorghum, then stir twice, and pour 50kg of bran husks. The bran is mixed 15 minutes before the steamer, and it is required to mix the grain powder, grains, and bran shells evenly. Among them, the auxiliary material bran husk is steamed before use, the steam pressure is 0.1Mpa, and steamed for 30 minutes after round steaming.

[0021]...

Embodiment 2

[0024] Embodiment two ferments with prior art method and prolongs the scheme of fermentation time

[0025] The process is the same as in Example 1, and the fermentation time is 12 months.

[0026] After distillation, the base wine was evaluated comprehensively. The evaluation personnel consisted of 10 professional wine tasters above the provincial level, and the numbered secret evaluation method was adopted. The evaluation and other quality parameters are shown in Table 2.

[0027] Embodiments three, four, and five only adjust the concentration of ethanol and do not feed air into the scheme

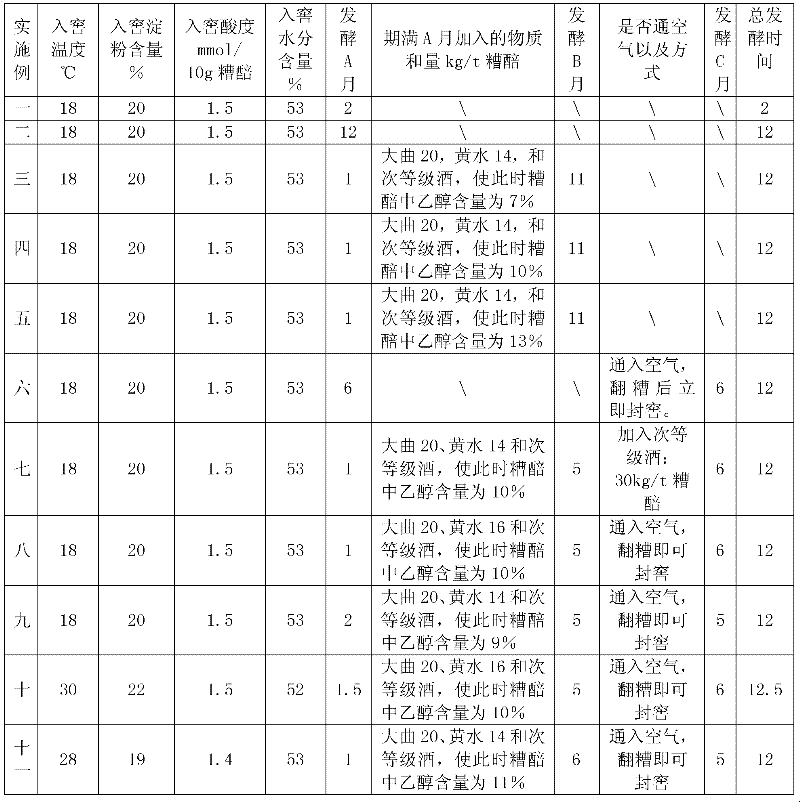

[0028] The bad unstrained spirits are fermented in the cellar according to the prior art method, and the parameters in the cellar are shown in Table 1.

[0029] After the fermented grains were sealed and fermented in the cellar for 1 month, Daqu, yellow water and low-grade wine were added, and the concentration of ethanol was controlled. Example 3 made the content of ethanol in the grain...

Embodiment 4

[0030] Embodiment 4 is the scheme of the present invention. After the fermented grains are sealed and fermented in a cellar for 1 month, Daqu, yellow water and low-grade wine are added, and the ethanol concentration is controlled so that the content of ethanol in the fermented grains is 10% by weight at this time. Sealed and fermented for another 11 months, the fermentation is completed, the cellar is opened, and the steps of mixing the grains and distilling are repeated.

[0031] After distillation, the base wine was evaluated comprehensively. The evaluation personnel consisted of 10 professional wine tasters above the provincial level, and the numbered secret evaluation method was adopted. The evaluation and other quality parameters are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com