Cooling method for 60-100mm performance-guaranteed thick steel plate after rolling

A cooling method and thick steel plate technology, applied in the direction of metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve problems such as mixed crystals, coarse grains, and backlog of steel plates, and achieve low requirements for process components and process operations The effect of simplicity and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

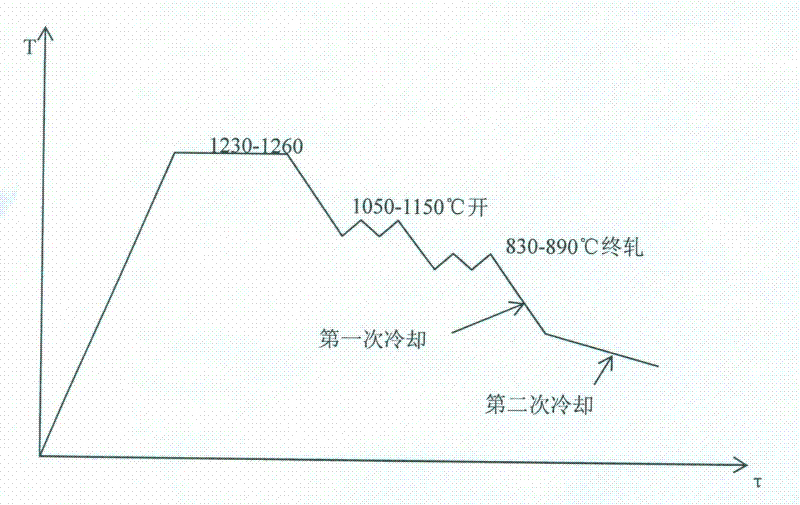

[0013] The cooling method of the 60-100mm thick steel plate after rolling of the present invention is to cool the extra-thick steel plate twice. The rapid cooling is used for the first time in the two cooling process, and the surface cooling rate of the steel plate is controlled above 12°C / s. Cooling time is 8~15s; the cooling rate of the second cold steel plate surface is controlled at 4~8℃ / s, and the second cooling time is calculated according to the redness temperature after the first cooling and the steel grade's requirements for the final redness temperature .

[0014] The ultra-thickness of the present invention is 60mm, 80mm, 100mm, low-alloy high-strength Q460C for performance and flaw detection. The steel plate contains the following chemical components (unit, wt%):

[0015] C: 0.08~0.16, Si: 0.20~0.50, Mn: 1.15~1.60, P: ≤0.020, S: ≤0.010, microalloying elements (Nb+V+Ti): ≤0.15, Als: ≤0.050, others are Fe and residual elements.

[0016] Steel rolling process point contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com