Porcelain composite insulator and manufacturing method thereof

A technology of porcelain composite insulators and insulating cylinders, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of low yield of high-voltage grades, high production costs, poor aging resistance, etc., and achieve improved pollution flashover resistance , Overcoming pollution flashover and high electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

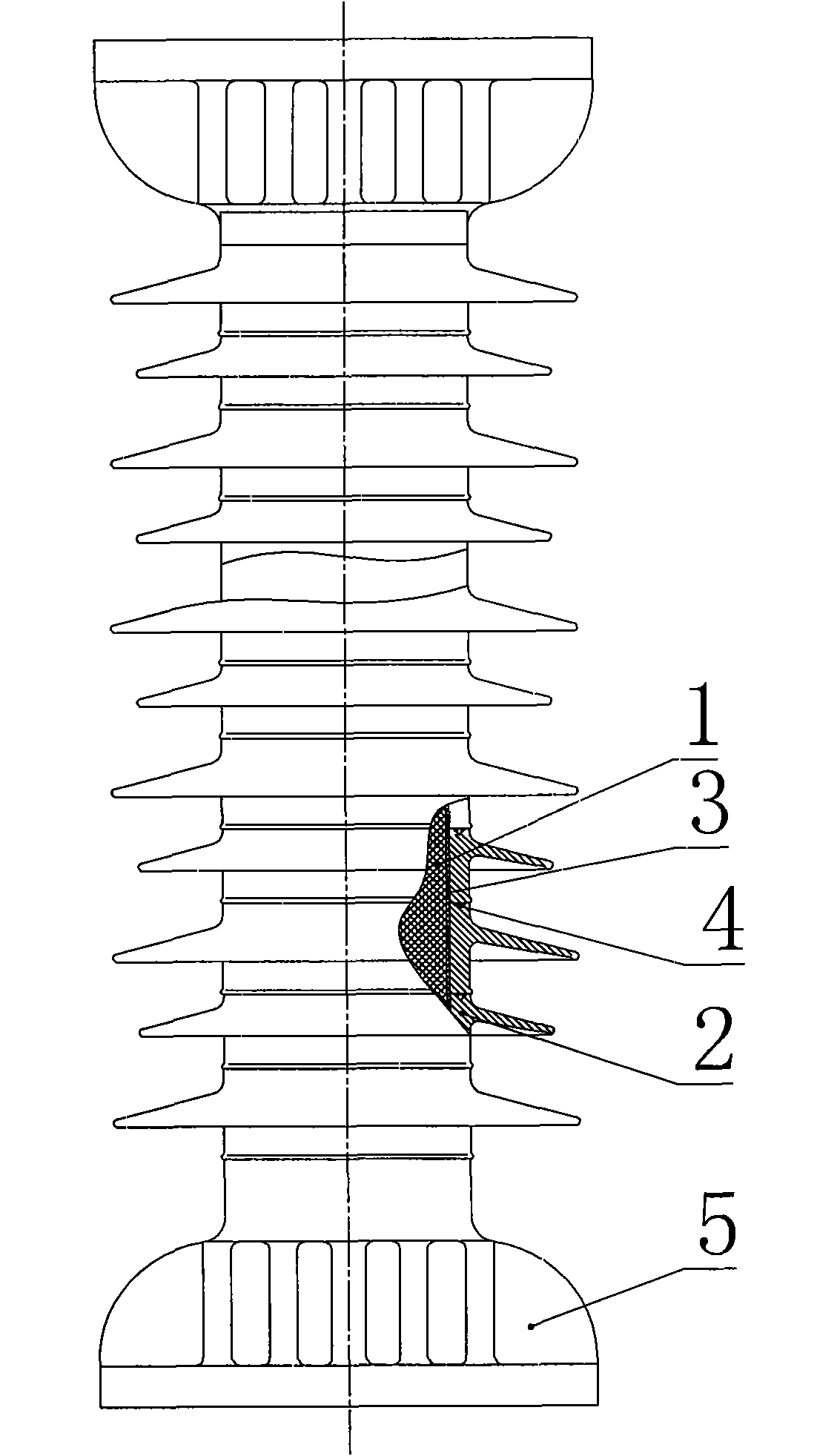

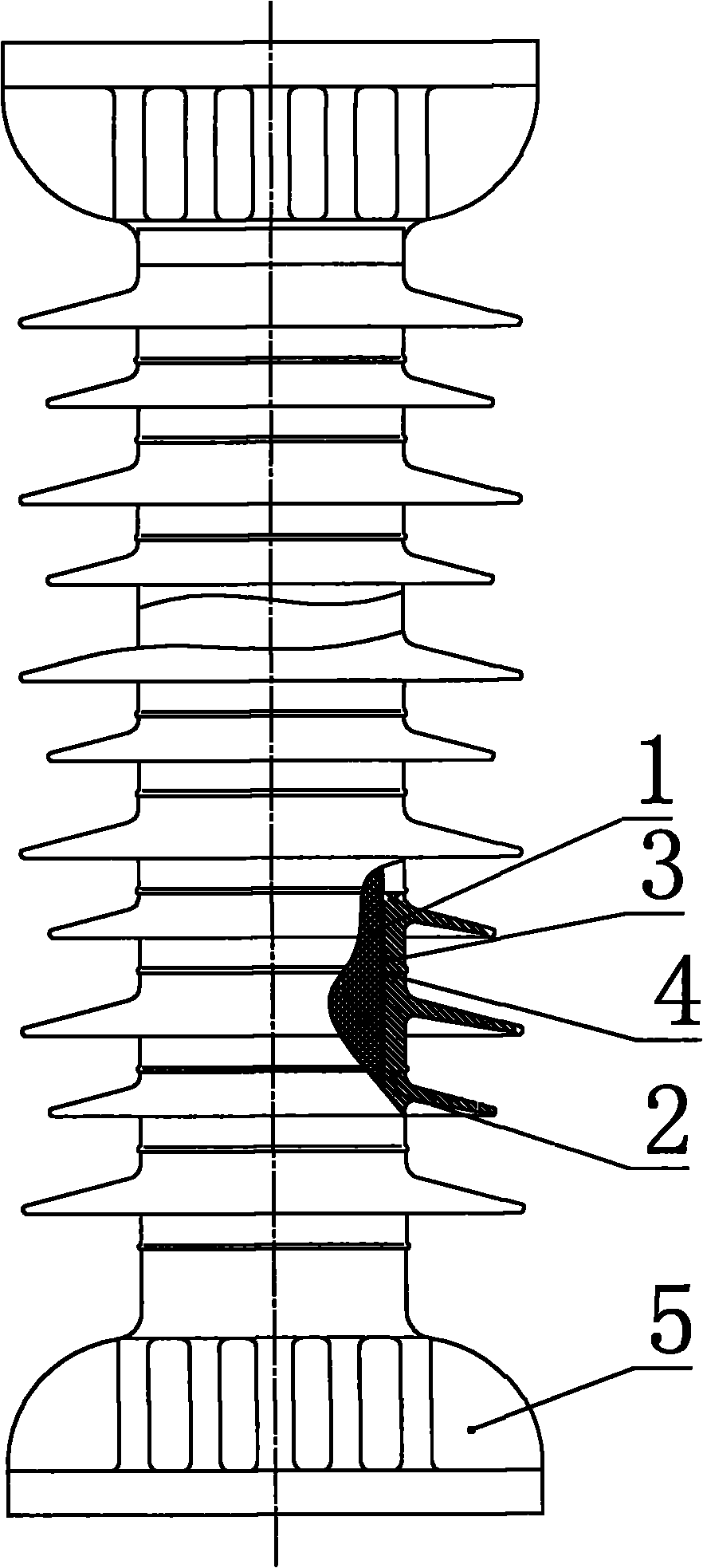

[0012] figure 1 The structure of the porcelain composite insulator of the present invention is shown. The insulating cylinder 1 is a glass fiber-wound reinforced epoxy cylinder with flanges 5 fixed at both ends. The insulating cylinder 1 is covered with a porcelain shed. There is an epoxy colloid 3 for bonding the two.

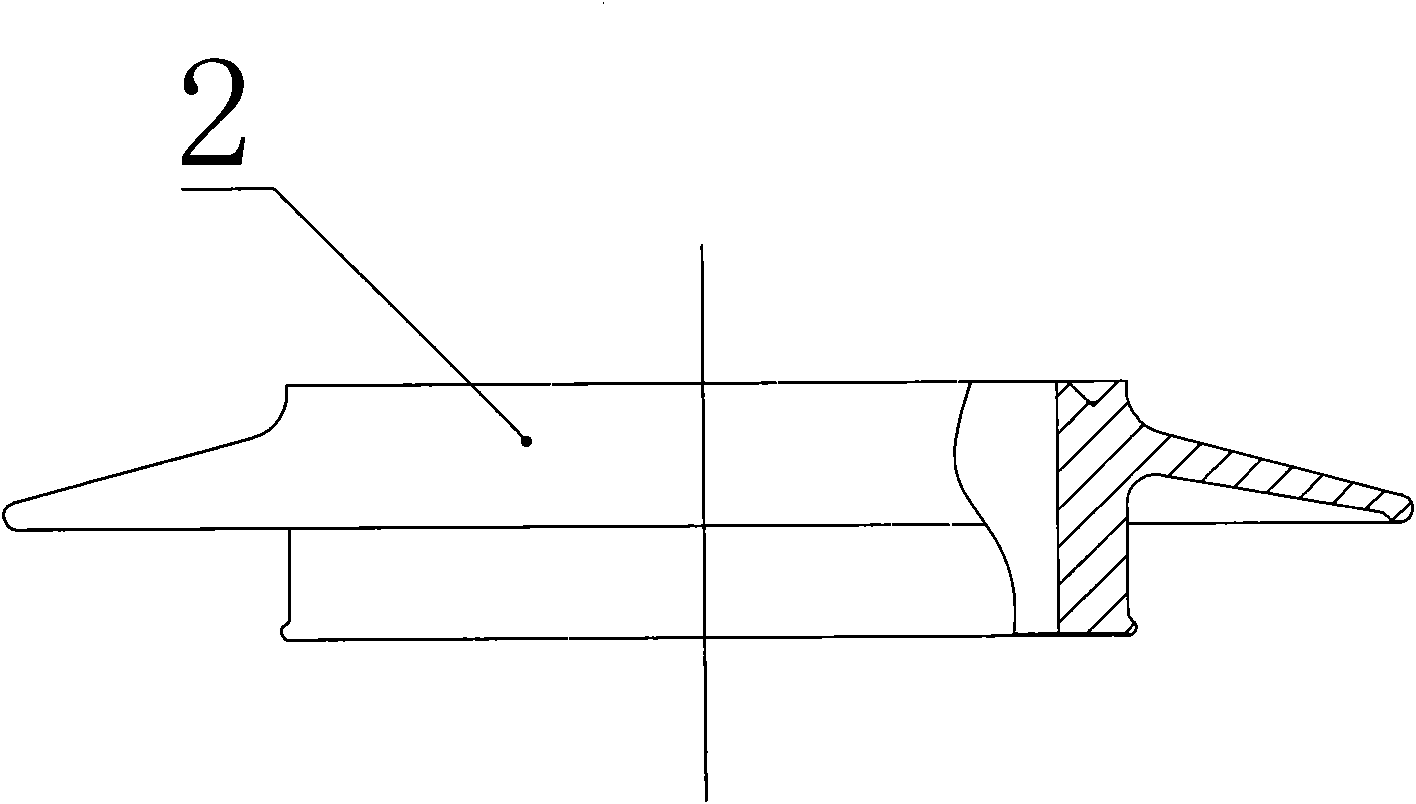

[0013] The porcelain umbrella skirt is composed of two or more sets of porcelain umbrella skirt segments connected in series, such as figure 2 As shown, there is a sealing groove at the connection of the ceramic shed segments 2 in series, and a sealing ring 4 can be embedded in the sealing groove to ensure the sealing and insulation effect when the ceramic shed segments 2 are connected in series.

[0014] When manufacturing the porcelain composite insulator of the present invention: firstly glue one end of the insulating tube 1 to the flange 5 and then fix two or more porcelain shed segments 2 in series on the insulating tube 1 from the end to the end. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com