Machining process for magnetic shoe

A processing technology and magnetic tile technology, applied in the field of magnetic tile processing, can solve the problems of energy waste, low product qualification rate, environmental pollution, etc., and achieve the effect of overcoming the low product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

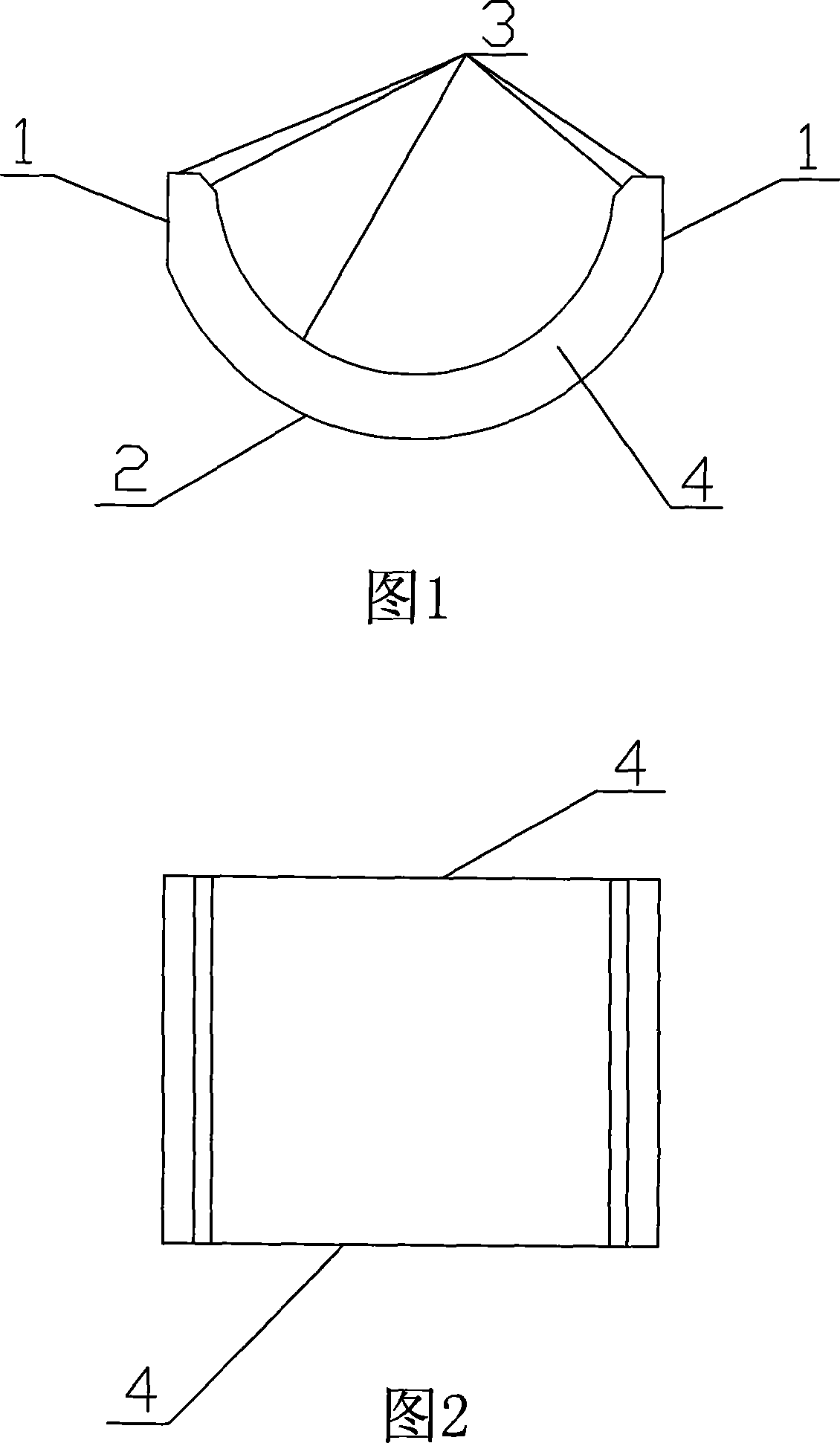

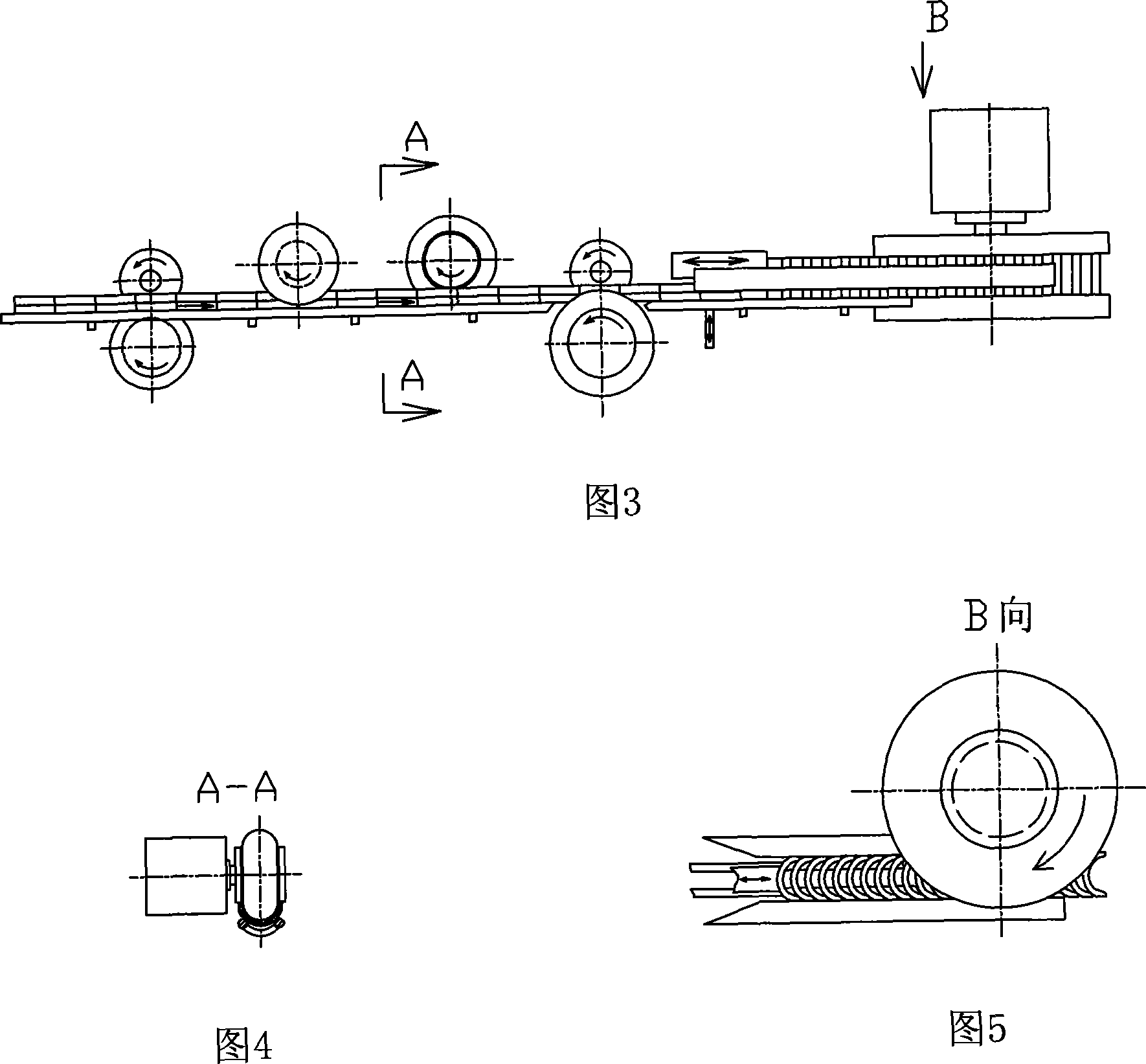

[0016] A processing technology for magnetic tiles, which has the process of die-casting magnetic tiles with rare earth materials and grinding the surface of blanks to form finished products. The surface grinding process of magnetic tiles is the process of grinding with shaped grinding wheels that match the structure and shape of the outer surface of magnetic tiles. And the surface of the magnetic tile is divided into four components such as the inner concave surface 3, the outer convex surface 2, the two side surfaces 1 and the two end surfaces 4 of the accompanying drawings 1 and 2, and are respectively ground by a corresponding shaped grinding wheel. The set guide rails are successively ground by four shaped grinding wheels through the conveying device to form finished products, as shown in Figure 3.

[0017] Still as shown in accompanying drawing 3, the grinding of the two sides 1, the inner concave surface 3, and the outer convex surface 2 of the magnetic tile is successive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com