Chip component mounting structure, chip component mounting method and liquid crystal display device

一种安装结构、部件的技术,应用在用电元件组装印刷电路、电气元件、电固体器件等方向,能够解决不合格、不能达成产品质量稳定化等问题,达到防止横向偏移的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described below with reference to the drawings. In addition, the same reference numerals are used for the same components, and detailed descriptions are appropriately omitted.

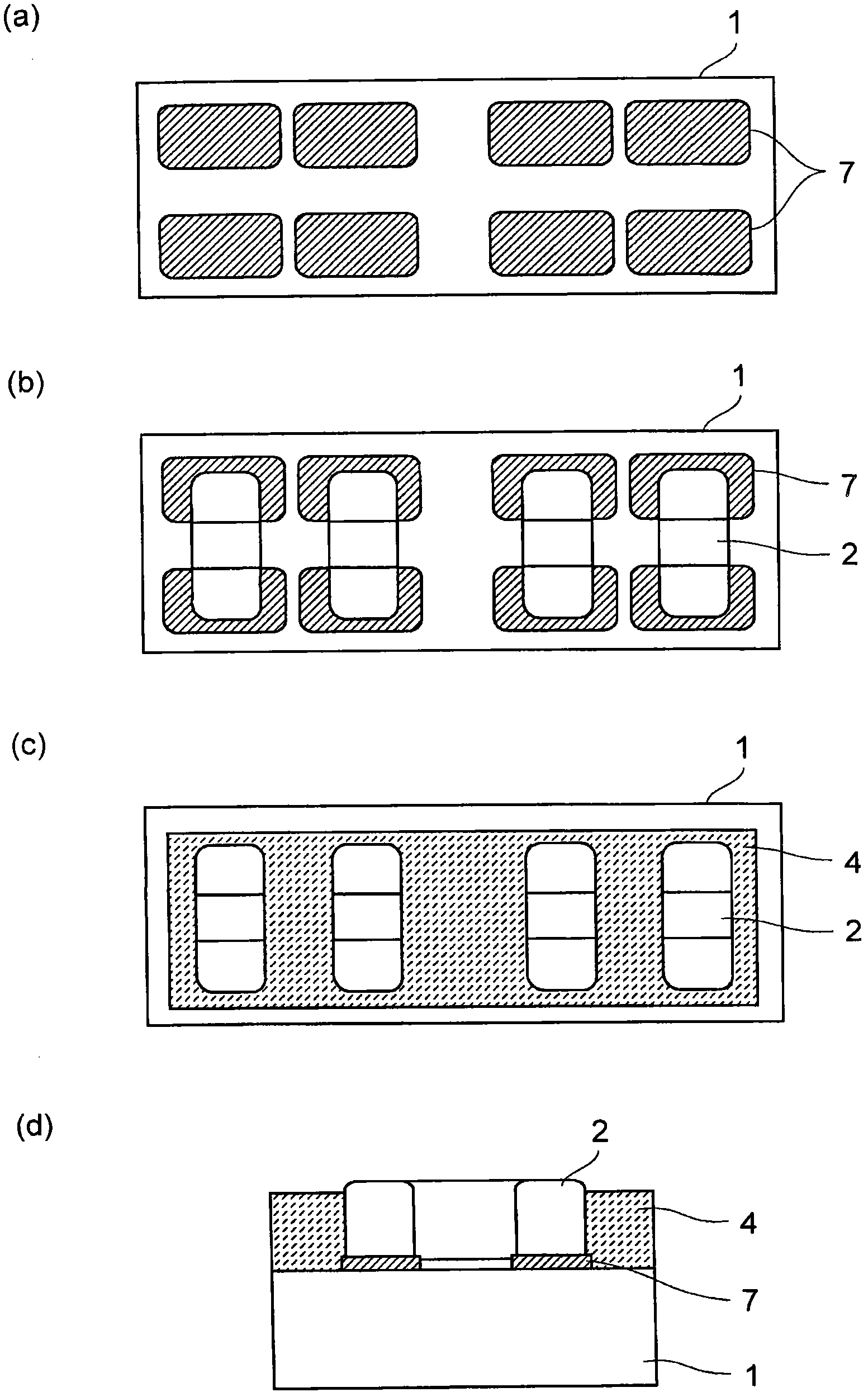

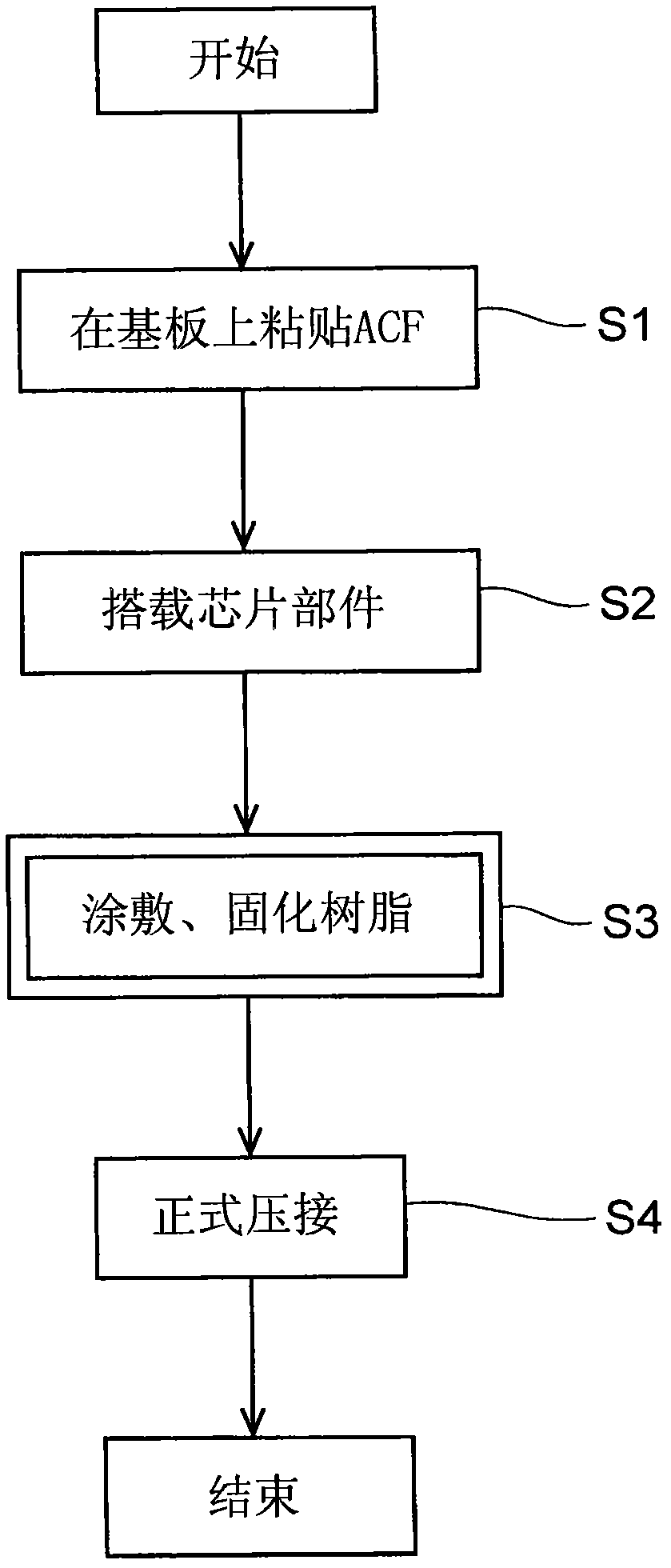

[0043] First, use figure 1 and figure 2 The chip component mounting method of this embodiment is demonstrated.

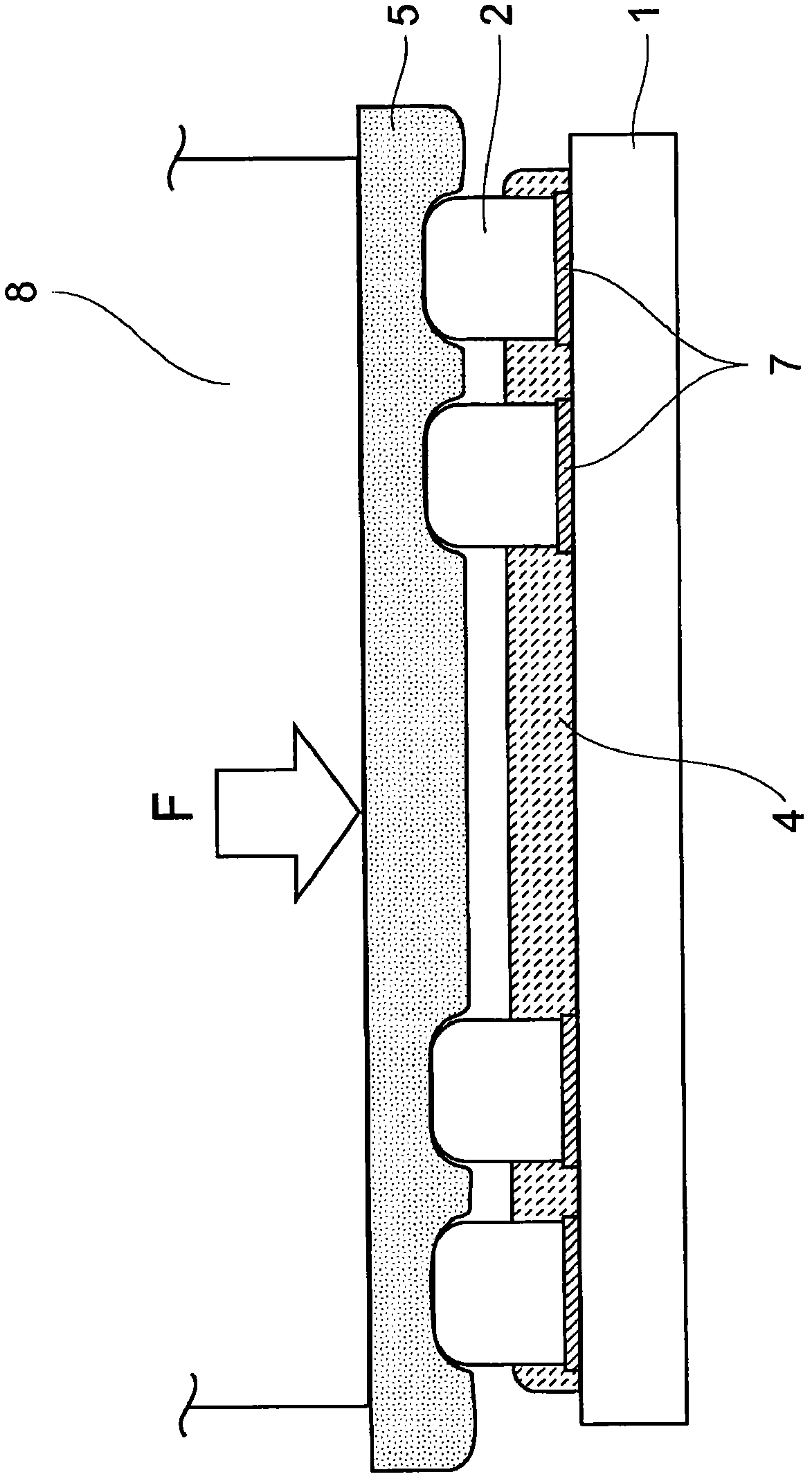

[0044] Such as figure 1 As shown, the chip component mounting method of the present embodiment is a chip component mounting method in which when a plurality of chip components 2 are mounted on a substrate 1 on which predetermined wirings are formed, predetermined electrodes, The anisotropic conductive film 7 is pasted on the connecting portion such as the connection pad, the chip component 2 is mounted on the anisotropic conductive film 7, and the chip component 2 is heated at a predetermined temperature through the elastic sheet 5. The crimping head 8 is pressurized with a predetermined pressure F for uniform crimping.

[0045] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com