Open type TBM (Tunnel Boring Machine) fullface synchronous lining trolley for hydraulictunnel

A hydraulic tunnel and lining trolley technology, which is applied in tunnel lining, shaft lining, tunnel, etc., can solve the problems of low hole forming speed, unfavorable tunnel safety and quality, etc., and achieve the effect of ensuring safety and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

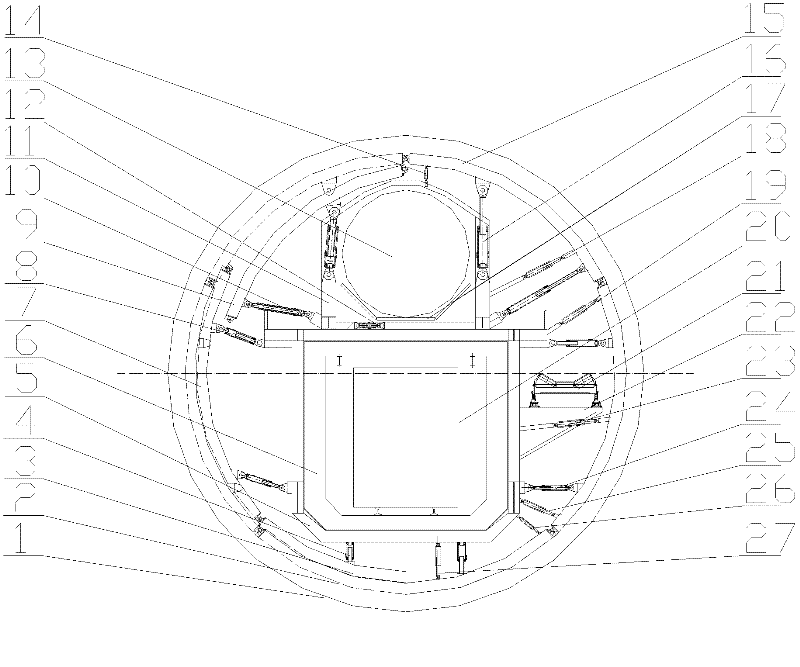

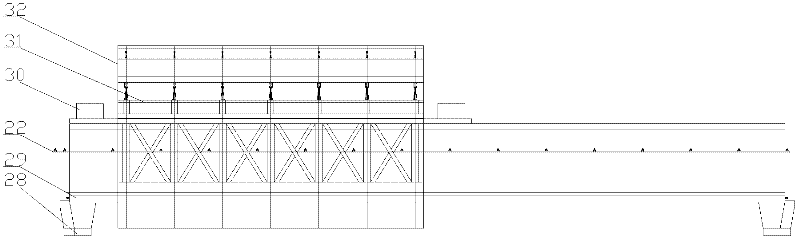

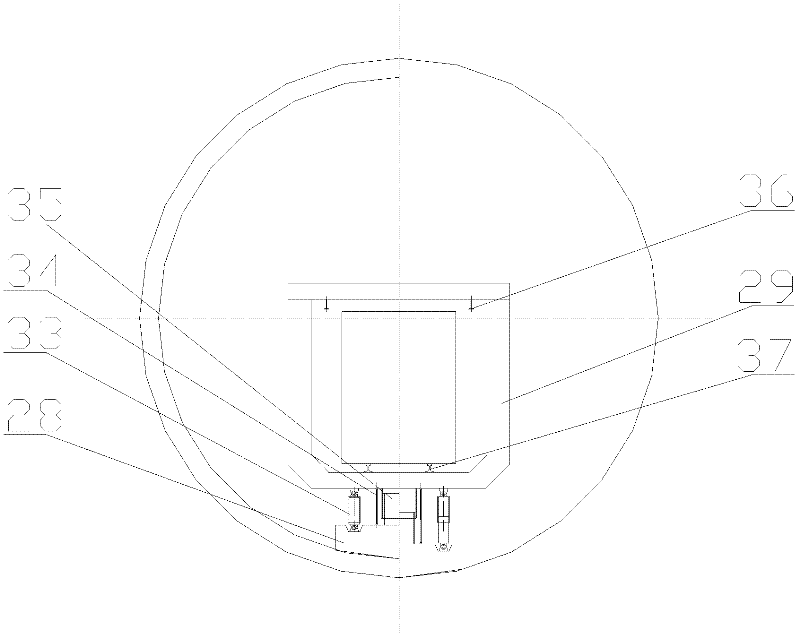

[0041] 1. If figure 1 and figure 2 As shown: the top mold (9, 15), the side mold (7), and the bottom mold (3) are a total of 5 groups of templates that together form a full-section template assembly (32), and the circumferential direction connection mode between each template is hinged, The axial connection mode is a bolt connection, and the hinge pin between the top form (9,15) and the side form (7) can be conveniently dismantled and installed, so as to be beneficial to demoulding and vertical formwork.

[0042] 2, the full-section template assembly (32) is a circular section, so it is impossible to realize variable diameter.

[0043] 3, stand assembly (31) is made up of top stand (11) and bottom stand (5).

[0044] 4. The upper platform (11) is a truss-type hollow structure, and there is enough space in the middle to facilitate the large-diameter ventilation hose (13) to pass through the trolley, and at the same time to minimize the resistance when the ventilation hose pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com