Positioning buckle column and heat dissipating device using the same

A technology of heat dissipation device and positioning buckle, applied in elastic/clamping device, circuit arrangement on support structure, cooling/ventilation/heating transformation, etc., can solve problems such as mistakes made by assemblers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

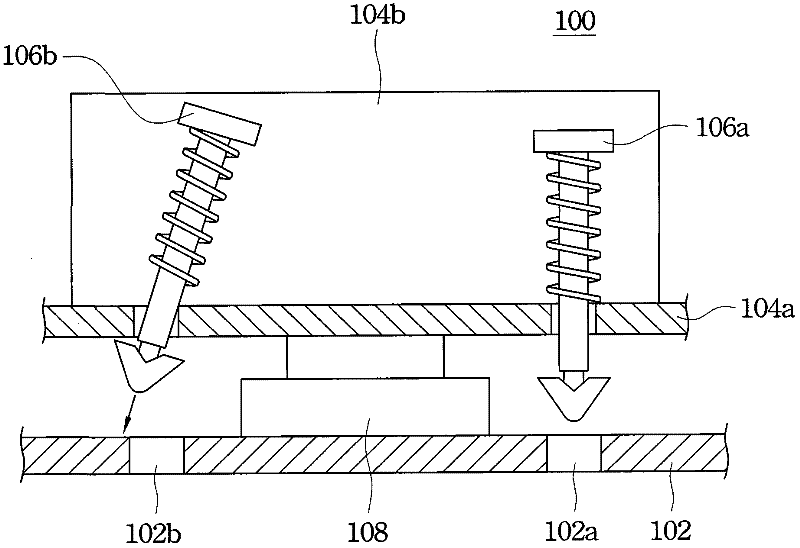

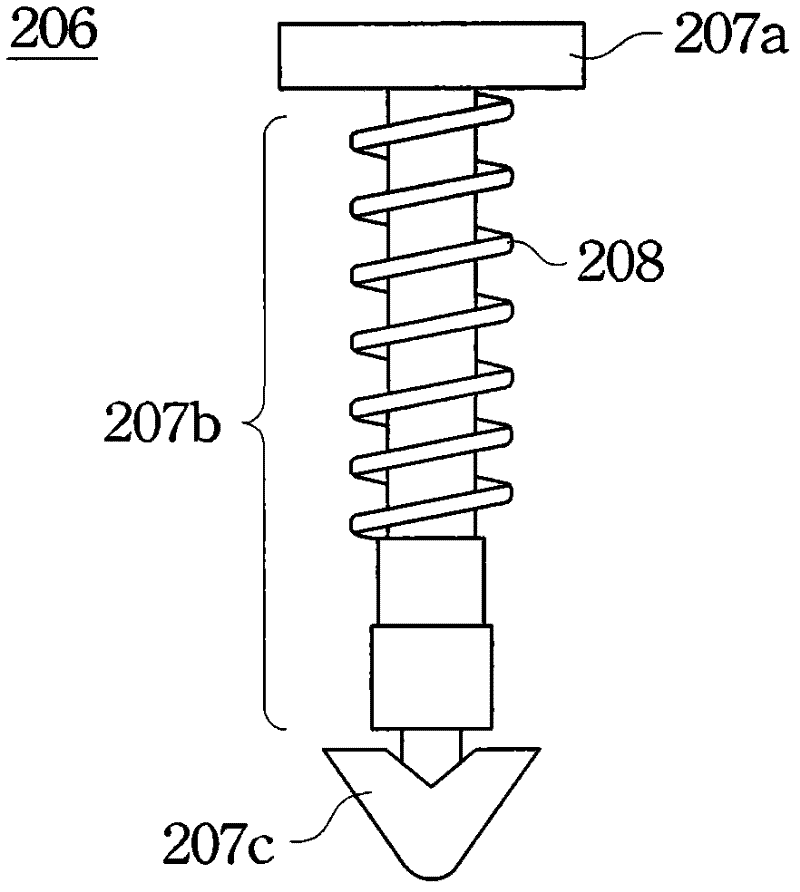

[0054] As mentioned above, the present invention provides a positioning buckle, which can control the distance that the locking portion of the bottom end protrudes from the bottom surface of the device to be fixed. The implementation details of applying the positioning studs to the heat sink will be described below with reference to the accompanying drawings.

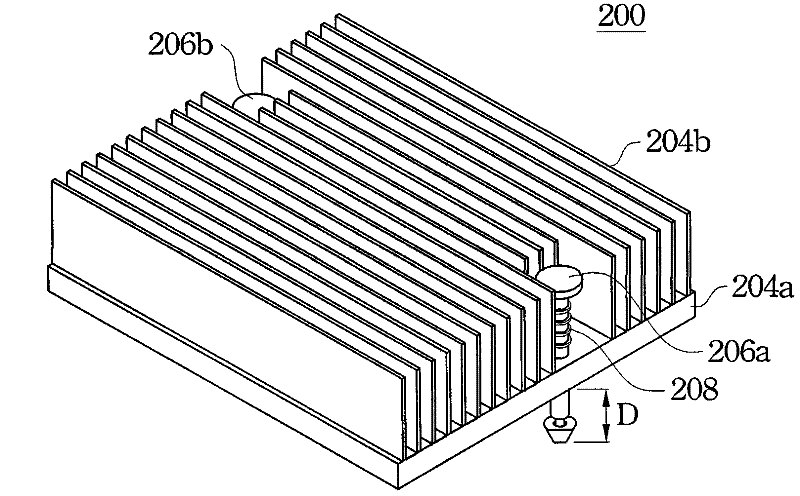

[0055] Please refer to figure 2 , which shows a perspective view of a heat dissipation device according to an embodiment of the present invention. The heat dissipation device 200 has a base plate 204a, a plurality of heat dissipation fins 204b and positioning pins (206a; 206b). The heat dissipation fins 204b and the base plate 204a may be an integrally formed heat dissipation structure of extruded aluminum or other heat dissipation structures of high thermal conductivity materials. The base plate 204a has a through hole through which a plurality of positioning buckle posts (such as the positioning buckle posts 206a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com