A kind of self-compacting concrete and preparation method thereof

A self-compacting concrete and mixture technology, which is applied in the field of self-compacting concrete and its preparation, can solve problems such as poor compacting effect, and achieve the effects of good gap passage, good segregation resistance, and shrinkage relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0018] Embodiment 1-3: a kind of self-compacting concrete, it is prepared by following method:

[0019] (1) mixing polycarboxylate high-performance water reducer with a small amount of water to obtain a mixture of polycarboxylate high-performance water reducer and water;

[0020] (2) Add water to cement, fly ash, and mineral powder to mix, then add acetonitrile and PAA aqueous solution, mix well, add medium sand with a fineness modulus of 3.0-2.3 and stone with a particle size of 15-20mm, mix ; Then add the mixture of polycarboxylate high-performance water reducer and water that step (1) obtains, mix homogeneously;

[0021] In step (2), in terms of parts by mass, the consumption ratio of cement and acetonitrile is 100: 2; in adding the mixture of sand, stone, polycarboxylate high-performance water reducer and water and the subsequent mixing process, acetonitrile gradually Volatile.

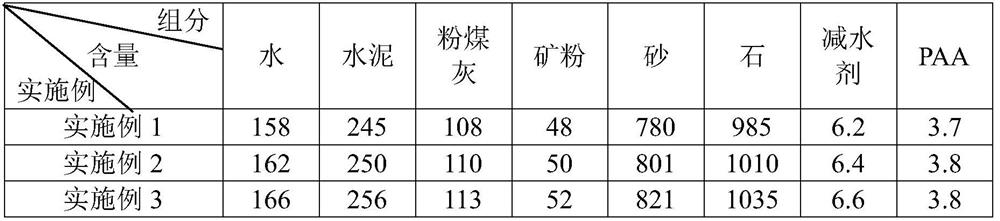

[0022] The formula of embodiment 1-3 is as shown in table 1.

[0023] The formula of table ...

Embodiment 4

[0025] Embodiment 4: A kind of self-compacting concrete, the difference with embodiment 2 is that in step (2), after adding water in the crushed cement, fly ash, ore powder, no acetonitrile is added.

Embodiment 5

[0026] Embodiment 5: a kind of self-compacting concrete, the difference with embodiment 2 is, in step (2), after adding water in the cement after pulverizing, fly ash, slag, the acetonitrile amount that adds is cement's 5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com