Algae clay mineral environmentally-friendly inner wall coating

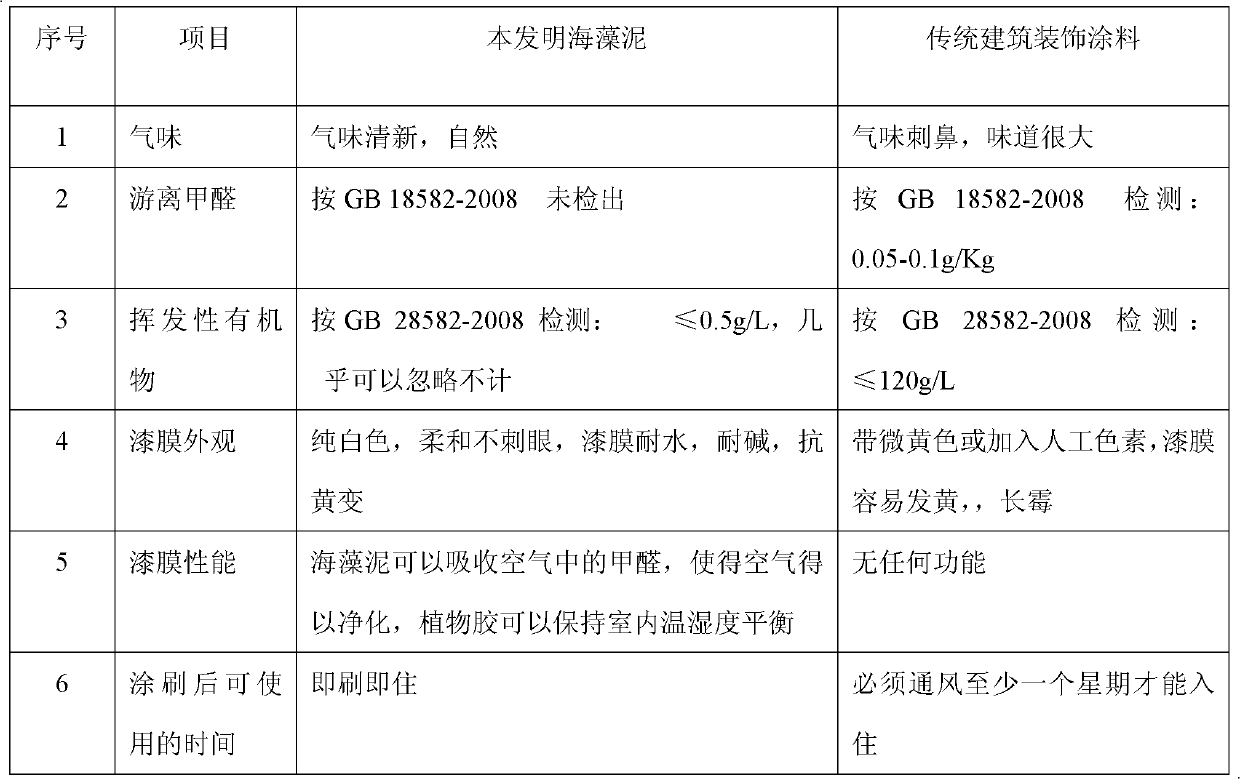

A technology for interior wall coatings and seaweed mud, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., which can solve the problems of water resistance, lack of stain resistance, no consumer, fading and discoloration, etc. problems, achieve strong stain resistance, improve storage stability and leveling, and high hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of decolorized seaweed mud powder:

[0043] ① Install a double-leaf agitator in the dispersion tank, put activated carbon at the bottom of the dispersion tank, and install a 100-mesh screen in the middle of the dispersion tank;

[0044] ②Secondly, pour 1 / 2 water into the dispersion tank, pour the seaweed mud from the deep sea of Hokkaido, Japan into the upper part of the dispersion tank (above the screen), start the double-bladed mixer, stir the seaweed mud or stir the seaweed mud and activated carbon at the same time , After stirring for 4h, let stand for 24h.

[0045] ③Then turn on the water, and the seaweed mud on the screen is decolorized seaweed mud powder. Before use, it can be dried to remove moisture, and the following examples all adopt the decolorized seaweed mud powder after drying.

Embodiment 1

[0047]Firstly, add 250.16kg of water, 1.00kg of ephedrine, 5.03kg of dispersant SN5040, 1.58kg of wetting agent CF-10, and 0.98kg of defoamer NXZ into the reaction kettle in sequence. Disperse (5~25)min, then add 150.00kg decolorized seaweed mud powder, 201.71kg R-902 titanium dioxide, 50.00kg talc powder, disperse (20~40)min at the speed (1000~1500)r / min, pass Sanding until the fineness of the material is ≤50μm; after sanding until the fineness of the material is ≤50μm, add 229.34kg of pure acrylic emulsion (ELASTENE TM (Erenda TM ) 3131NG), 40.61kg aloe vera plant glue, 14.21kg glycerin, 2.03kg fungicide ethanol (75%), 0.97kg defoamer NXZ, 0.91kg British Saul RS preservative, at a speed of (300-900) r / Disperse in min (10-30) min. Finally, use 9.84kg vegetable glue and 41.69kg water to adjust the viscosity, so that the viscosity is (100±5) KU at (25±1)°C, and a white flowing liquid is obtained after passing through a 200-mesh sieve, which is the invention product. Product ...

Embodiment 2

[0049] First add 232.34kg of water, 0.97kg of ephedrine, 4.92kg of dispersant SN5040, 1.37kg of wetting agent CF-10, and 1.02kg of defoamer NXZ into the reactor in sequence, disperse at a medium speed for 5-10min, and then add 163.51kg Decolorized seaweed mud powder, 219.64kg R-902 titanium dioxide, 48.93kg talcum powder, disperse at high speed for 10-15min, and then add 212.62kg of pure acrylic emulsion (ELASTENE TM (Erenda TM ) 3131NG), 37.41kg vegetable gum, 13.70kg glycerin, 1.86kg fungicide ethanol (75%), 0.95kg defoamer NXZ, 0.94kg fungicide RS, disperse at medium speed for 10-15min. Finally, adjust the viscosity with 11.63kg aloe vera plant glue and 40.58kg water, so that the viscosity is (100±5) KU at (25±1)°C. After passing through a 200-mesh sieve, a white flowing liquid is obtained, which is the invention product. See Table 1 for performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com