Cefetamet pivoxil hydrochloride capsule and preparation method thereof

A technology for preparing ceftamet pivoxil hydrochloride and capsules, which can be used in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., and can solve problems such as easy aggregation of ceftamet pivoxil hydrochloride, long process flow, and large amount of excipients , to achieve the effect of reducing agglomeration, low moisture, promoting dissolution and release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

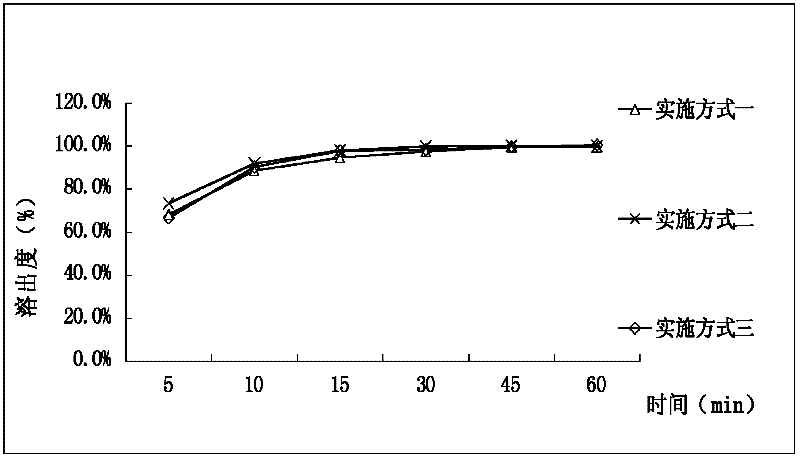

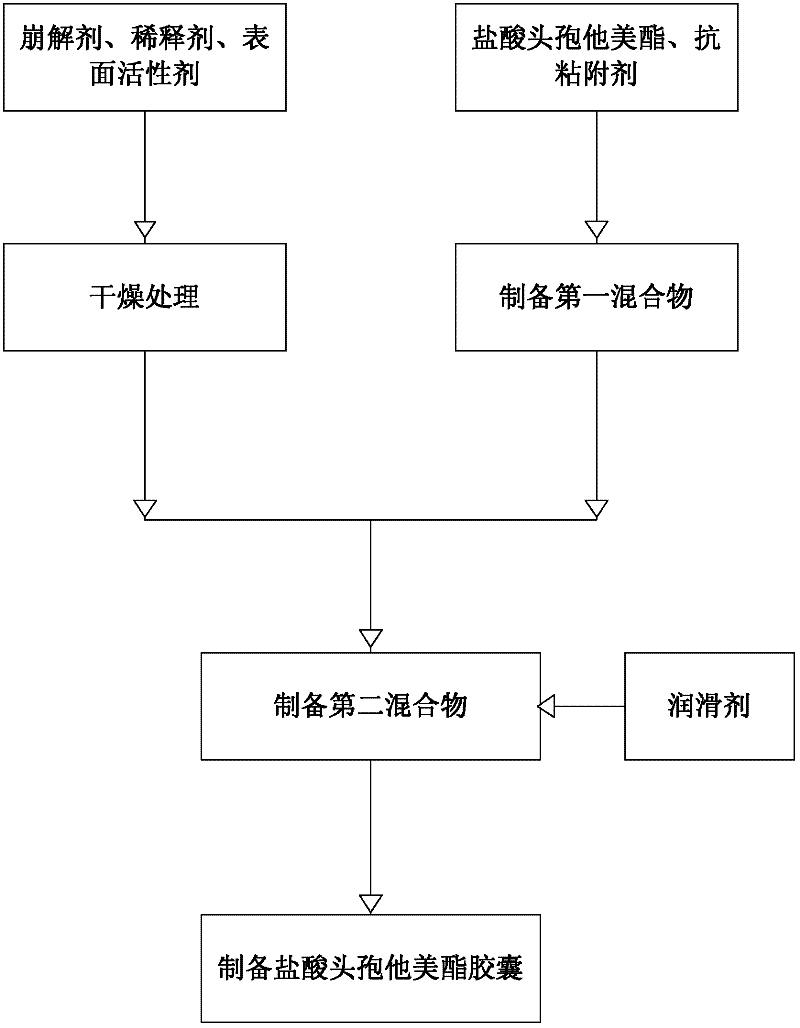

[0031] see figure 2 , figure 2 Show the embodiment of the present invention ceftazidime pivoxil hydrochloride capsule preparation method principle diagram, comprise the steps:

[0032] Step S01, drying process:

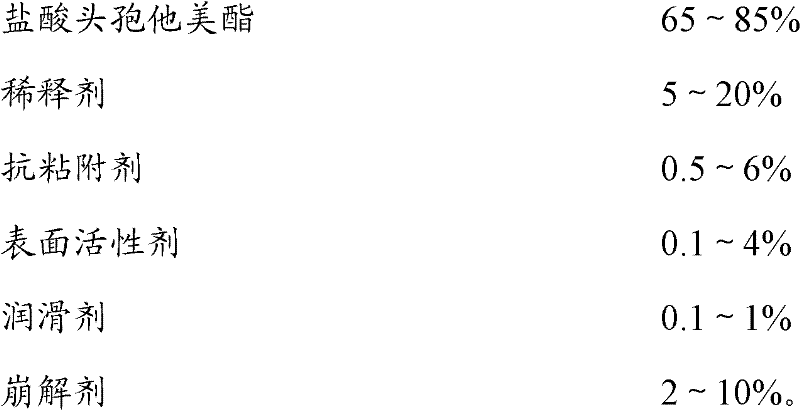

[0033] The components in the following weight percentages are dried separately:

[0034] Thinner 5~20%

[0035] Surfactant 0.1~4%

[0036] Disintegrant 2~10%;

[0037] Step S02, preparing the first mixture:

[0038] The components in the following weight percentages are mixed to obtain the first mixture:

[0039] Ceftazidime pivoxil hydrochloride 65~85%

[0040] Anti-adhesive agent 0.5-6%;

[0041] Step S03, preparing the second mixture:

[0042] mixing the first mixture, the dried diluent, surfactant and disintegrant, adding a lubricant with a weight percentage of 0.1 to 1%, and stirring to obtain a second mixture;

[0043] Step S04, preparing ceftazidime hydrochloride capsules:

[0044] The second mixture was filled into capsules to obtain ceftazidime h...

Embodiment 1

[0051] The ceftazidime hydrochloride capsule of the present embodiment one has the following components in weight percentage:

[0052]

[0053]

[0054] The preparation method of ceftazidime hydrochloride capsules of the present invention comprises the following steps:

[0055] (1), get cefetamet pivoxil hydrochloride 1212.18g, colloidal silicon dioxide N 20 62.3g, microcrystalline cellulose 272.18g, starch 50g, low-substituted hydroxypropyl cellulose 92.56g, crospovidone 71.2g, poloxamer 1.78g, magnesium stearate 17.8g;

[0056] (2), drying of auxiliary materials:

[0057] Dry the microcrystalline cellulose, starch, low-substituted hydroxypropyl cellulose, crospovidone and poloxamer in the above (1) at 105°C until the moisture content is 1%, and pass through a 80-mesh sieve respectively ;

[0058] (3), mixing:

[0059] Ceftazidime hydrochloride and colloidal silicon dioxide N in the above-mentioned (1) 20 Mix, cross 80 mesh sieves, obtain the first mixture;

[0060]...

Embodiment 2

[0064] The ceftazidime hydrochloride capsule of the present embodiment two has the following components in weight percentage:

[0065]

[0066]

[0067] The preparation method of ceftazidime hydrochloride capsules of the present invention comprises the following steps:

[0068] (1), get cefetamet pivoxil hydrochloride 1276.26g, colloidal silicon dioxide N 20 80.1g, microcrystalline cellulose 178g, pregelatinized starch 71.2g, crospovidone 129.94g, poloxamer 35.6g, talc 8.9g;

[0069] (2), drying of auxiliary materials:

[0070] Dry the microcrystalline cellulose, precrosslinked starch, crospovidone and poloxamer in the above (1) at 105° C. until the moisture content is 1%, and pass through 80-mesh sieve respectively;

[0071] (3), mixing:

[0072] Ceftazidime hydrochloride and colloidal silicon dioxide N in the above-mentioned (1) 20 Mix and pass through an 80-mesh sieve to obtain the first mixture;

[0073] (4), add microcrystalline cellulose, starch, low-substitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com