Highly flexible cable utilized by rail transit vehicle

A rail transit vehicle, highly flexible technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of molecular mobility and air heat loss, high temperature sensitivity, easy to harden materials, etc. High hardness and toughness, good electrical properties, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

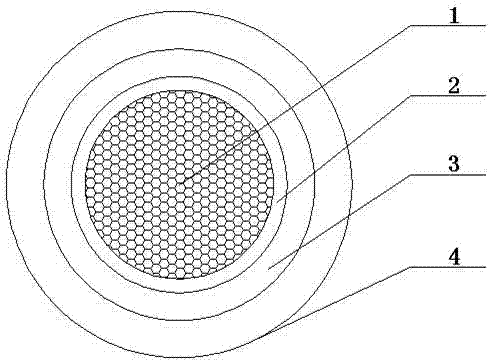

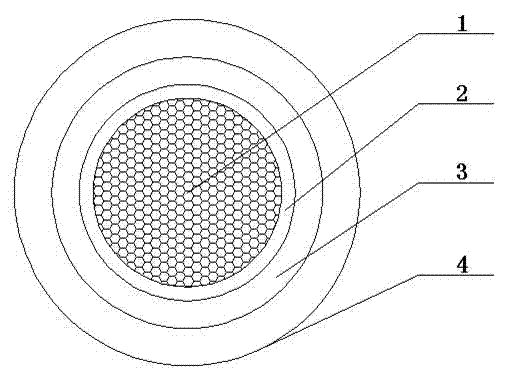

[0017] See figure 1 , the present invention includes a cable core conductor 1, and the outside of the cable core conductor 1 is provided with an inner lining layer 2, an insulating layer 3, and an outer sheath 4 sequentially from the inside to the outside. The cable core conductor 1 is made of tinned copper monofilament bundles according to left-hand normal twisting. Alternatively, the outermost two layers of the cable core conductor 1 are formed by normal left-hand twisting of tinned copper wires, and the remaining layers are formed by left-hand normal twisting of tinned copper wires.

[0018] The bundled wires composed of the above-mentioned tinned copper wires are stranded in the left direction or tinned copper wires in the left direction. Arrange 6 bundled wires or tinned copper wires, and then add 6 bundled wires or tinned copper wires for each layer when going outward. 9, 11, 13, 15.... The number of layers (or cross-sectional area of the cable core conductor) and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com