Method for preparing high-purity porous iron film by adopting electrochemical method

A porous iron and thin film technology, applied in electroforming, electrolysis process, etc., can solve the problems of poor iron oxidation resistance, etc., achieve high porosity, wide application range, and simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

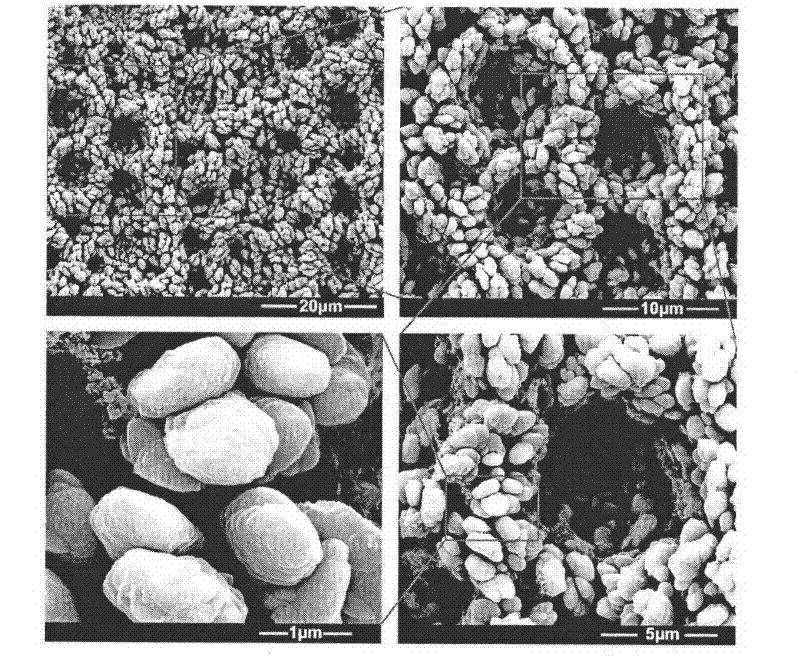

[0027] The electroplating solution is composed of: ferrous chloride 0.1-0.3M, hydrochloric acid to control the pH of the electroplating solution 0-2, sodium dodecylbenzenesulfonate 0.05-0.5wt%, and the current density is selected to be 1-3A / cm 2 . Plating time 10 ~ 30s. The obtained high-purity porous iron film has a pore size of about 5 μm and a good microscopic appearance.

Embodiment 2

[0029] The electroplating solution is composed of: ferrous ammonium sulfate 0.1-0.3M, sulfuric acid controls the pH of the electroplating solution 0-2, sodium dodecyl sulfate 0.05-0.5wt%, and the current density is selected to be 1-3A / cm 2 . Plating time 10 ~ 30s. The pore size of the obtained high-purity porous iron film is about 3 μm, and the pore wall structure is good.

Embodiment 3

[0031] The electroplating solution is composed of: ferrous acetate 0.1-0.3M, carboxylic acid to control the pH of the electroplating solution 0-2, OP-10 surfactant 0.05-0.5wt%, the current density selection 1-3A / cm 2 . Plating time 10 ~ 30s. The pore size of the obtained high-purity porous iron film is about 5 μm, and the particles constituting the pore wall structure are relatively small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com